The Long Span Roll Forming Machine Revolutionizing Metal Fabrication

In the realm of modern manufacturing, innovation is a key driving force. The introduction of advanced machinery has transformed various processes, particularly in the metal fabrication industry. One such technological advancement is the long span roll forming machine. This specialized equipment is designed to shape and fabricate metal sheets into long, continuous profiles, making it a critical tool in manufacturing sectors like construction, automotive, and appliance production.

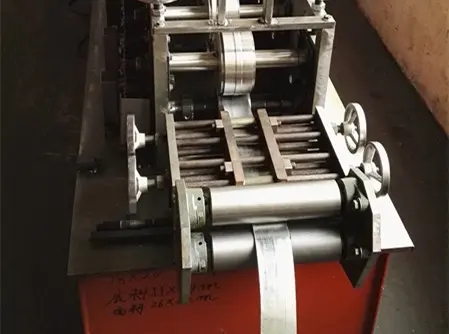

Understanding Roll Forming

Before delving into the specifics of long span roll forming machines, it is essential to understand the fundamental process of roll forming. Roll forming is a continuous bending operation in which a strip or sheet of metal is passed through a series of rollers that gradually shape the material into the desired cross-section. This method is preferred for producing long lengths of materials with consistent dimensions and high accuracy.

The Advantages of Long Span Roll Forming Machines

Long span roll forming machines offer numerous advantages over traditional metal forming techniques. One of the most significant benefits is the ability to produce long, continuous profiles without joints, which enhances the strength and durability of the finished product. For applications such as roofing, siding, and structural components, this feature is invaluable, as it reduces the potential for leaks and weak points in the construction.

Moreover, these machines allow for high production speeds, which can significantly improve manufacturing efficiency. A long span roll forming machine can produce components at a rate that traditional fabrication methods cannot match. This capability not only increases output but also helps reduce labor costs, as operators can oversee the high-speed production of multiple lengths simultaneously.

Customization and Versatility

One of the defining characteristics of long span roll forming machines is their versatility. They can be customized to produce various profiles, from simple shapes to complex designs tailored to specific applications. This flexibility is crucial for industries that require bespoke solutions, as it enables manufacturers to meet unique architectural or engineering specifications.

Furthermore, modern long span roll forming machines incorporate advanced technology, including computer-controlled systems that optimize production parameters. These features allow for quick changeovers between different profiles, facilitating the efficient production of diverse products within the same operational cycle.

Materials and Applications

Long span roll forming machines are typically used with a variety of materials, including steel, aluminum, and galvanized metals. The choice of material depends on the intended application and required properties. For instance, galvanized steel is often chosen for roofing applications due to its corrosion resistance, while aluminum may be preferred for lightweight structures and aesthetic finishes.

Applications for long span roll forming are extensive. In the construction industry, these machines are used to create roofing and siding panels that are both durable and visually appealing. In the automotive sector, they help manufacture components that are lightweight yet robust, contributing to overall vehicle efficiency. Additionally, appliances such as refrigerators and air conditioning units can benefit from components produced through this method, which require precise shapes and finishes.

Conclusion

The long span roll forming machine represents a significant advancement in the field of metal fabrication. Its ability to produce long, continuous profiles with high precision and efficiency makes it an invaluable asset across various industries. By embracing this innovative technology, manufacturers can enhance production capabilities, reduce costs, and deliver high-quality products tailored to the needs of their clients.

As the demand for custom metal components continues to grow, the long span roll forming machine stands out as a crucial player in the evolution of manufacturing practices. With ongoing advancements in technology, the future of roll forming looks promising, paving the way for even more efficient and innovative applications in the years to come.