Navigating the intricate landscape of large span roll forming machines requires a deep understanding of their capabilities and the nuances of the industries they serve. These machines have revolutionized construction and manufacturing by offering unparalleled customization and efficiency gains. Their ability to produce expansive metal components ensures they remain indispensable for projects demanding precision and durability.

In the realm of construction, large span roll forming machines have emerged as a pivotal component for fabricating metal roofing systems, steel walls, and structural beams. These machines offer unparalleled flexibility, capable of producing components in a variety of shapes, sizes, and materials, tailored to the specific requirements of a building project. They facilitate the creation of seamless panels, reducing junctions and potential leakage points, which significantly enhances the longevity and reliability of structures.

For manufacturers, the operational benefits of large span roll forming machines are compelling. The efficiency of production lines can be dramatically increased due to the machines’ ability to form continuous lengths of metal components with minimal waste. This not only underscores a commitment to sustainability by reducing material wastage but also ensures cost-effectiveness by minimizing the need for excess inventory.

A key advantage these machines offer is their precision engineering and design versatility. Advanced control systems integrated into modern large span roll forming machines allow operators to make quick adjustments to the roll profile, thickness, and material type. This adaptability is a crucial feature for manufacturers who must meet diverse customer specifications without incurring additional downtime or retooling costs.

In industries where product specification adherence is non-negotiable, such as aerospace or automotive sectors, the precision of large span roll forming machines is invaluable. They guarantee uniformity and exceptional structural integrity, qualities that are critical when manufacturing components that contribute to the safety and resilience of these vehicles.

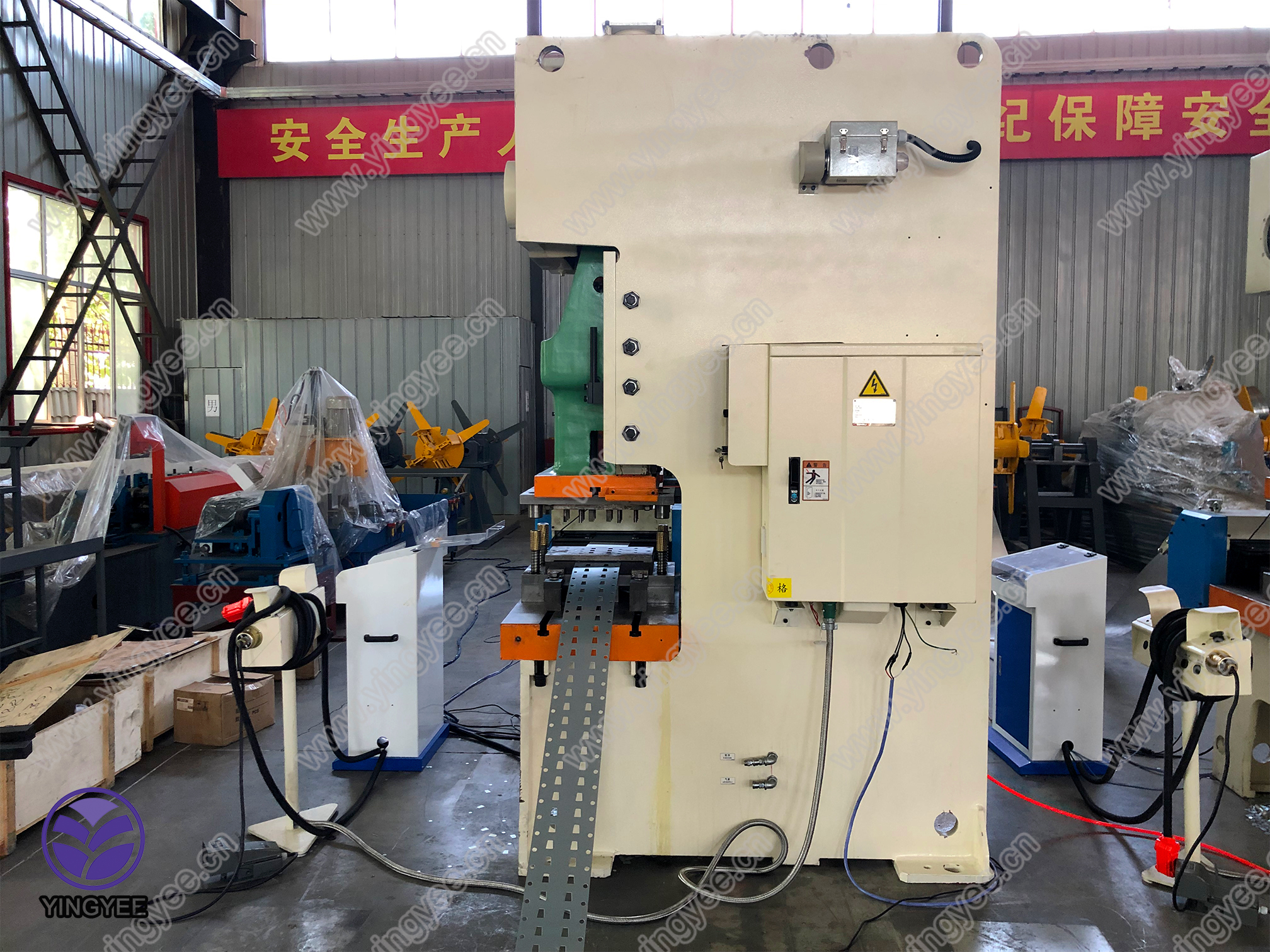

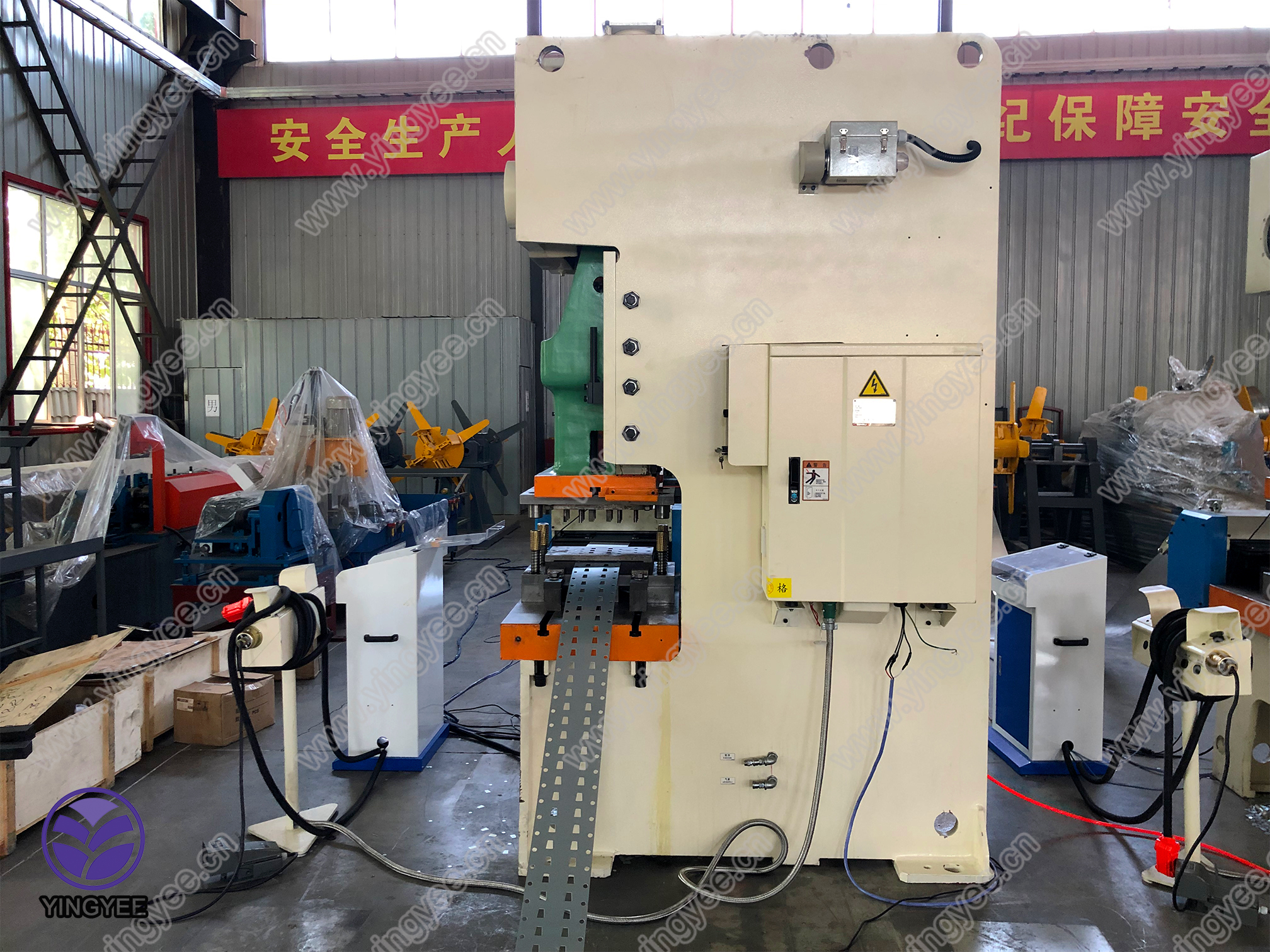

large span roll forming machine

Furthermore, the expertise required to operate and maintain these sophisticated machines underscores their complexity. Skilled technicians must be adept in both the mechanical and digital domains, understanding the intricacies of roll forming processes, maintenance schedules, and software programming to ensure optimum machine performance.

Large span roll forming machines are designed for reliability and longevity. Their robust build and high-quality components mean they can withstand the rigors of continuous, high-volume production. Regular maintenance and part replacement ensure that these powerhouse machines continue to operate at peak efficiency, reducing downtime and extending their service life.

In terms of trustworthiness and authority, manufacturers of large span roll forming machines often provide comprehensive training and support to their clients. This hands-on approach not only facilitates a smoother integration of the machinery into existing production lines but also instills confidence in operators who must rely on these machines for their day-to-day operations. Furthermore, manufacturers frequently update machine software to incorporate the latest advancements in technology, ensuring that their clients remain at the cutting edge of production capabilities.

The economies of scale that large span roll forming machines offer can be transformative for businesses looking to expand their production capabilities or enter new markets. By streamlining production processes, companies can achieve competitive pricing while maintaining the high quality that their clients expect.

In conclusion, investing in large span roll forming machines is a strategic decision that can significantly elevate a company's manufacturing processes. Their capabilities align with the modern needs of industries that demand flexibility, precision, and sustainability. By reducing costs and increasing production efficiency, these machines not only enhance productivity but also align with global trends toward efficient, eco-friendly manufacturing solutions. For companies committed to innovation and excellence, leveraging the power of large span roll forming machines is a fundamental move toward future success.