High-Speed Galvanized Storage Beam Roll Forming Machine Revolutionizing the Storage Solutions Industry

In the fast-paced world of industrial manufacturing and storage solutions, efficient machinery plays a crucial role. One such innovative piece of equipment is the high-speed galvanized storage beam roll forming machine. This sophisticated machine is designed to streamline the production process of storage beams, which are essential components in warehouses, distribution centers, and various storage facilities. In this article, we will explore the features, benefits, and applications of high-speed galvanized storage beam roll forming machines.

Understanding Roll Forming Technology

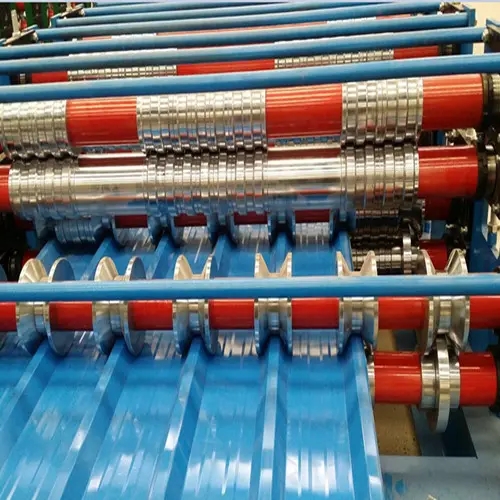

Before delving into the specifics of the high-speed galvanized storage beam roll forming machine, it’s important to understand the basics of roll forming technology. Roll forming is a continuous bending process in which a long strip of metal is passed through a series of rollers. Each roller gradually shapes the metal into the desired profile without cutting or altering the fundamental characteristics of the material. This process is not only efficient but also minimizes waste, making it an environmentally friendly option for manufacturers.

Features of High-Speed Galvanized Storage Beam Roll Forming Machines

High-speed galvanized storage beam roll forming machines are engineered with cutting-edge technology and features that enhance productivity

1. Speed and Efficiency As the name suggests, these machines operate at high speeds, significantly reducing the production time for storage beams. Advanced automation and synchronized controls allow for rapid formation without compromising accuracy.

2. Galvanization The machines are designed to form beams that are galvanized, providing a protective coating of zinc. This process enhances the corrosion resistance of the steel beams, making them suitable for various environments, particularly in warehouses exposed to humidity or other corrosive elements.

3. Customizable Profiles These roll forming machines can be easily adjusted to produce different profiles of storage beams, catering to specific client needs. This flexibility is essential in today’s market, where customized solutions are in high demand.

4. Integrated Cutting and Punching Many high-speed roll forming machines come equipped with integrated cutting and punching stations, allowing producers to create not only beams but also additional features such as holes for mounting and other configurations on the same setup. This integration reduces material handling and overall processing times.

5. User-Friendly Controls Modern machines are outfitted with intuitive control systems that enable operators to easily manage production parameters, monitor quality, and perform maintenance, thus minimizing downtime and maximizing output.

Benefits of Using High-Speed Roll Forming Machines

The adoption of high-speed galvanized storage beam roll forming machines brings forth a myriad of benefits

- Increased Production Capacity With enhanced speed and efficiency, manufacturers can meet rising demand without needing to invest in additional machinery or labor.

- Quality Assurance Consistent and precise manufacturing processes ensure high-quality end products. Galvanized beams have superior durability and reliability, essential for storage applications.

- Cost Savings The reduction in waste and the ability to produce beams in bulk can lead to significant cost savings. Moreover, minimizing the manual labor required for production lowers overall operational costs.

- Environmental Sustainability By reducing material waste and producing long-lasting products, these machines contribute to a more sustainable manufacturing process.

Applications of Galvanized Storage Beams

Galvanized storage beams are commonly employed in various sectors, including

- Warehousing and Distribution They are crucial in the construction of racking systems that maximize storage capacity and improve inventory management. - Manufacturing Facilities Used to create robust storage solutions that can withstand heavy loads and be easily adjustable.

- Retail and Commercial Spaces Provide structural support for shelving and display systems, enhancing the overall functionality of retail environments.

Conclusion

The high-speed galvanized storage beam roll forming machine stands as a testament to the advancements in manufacturing technology. By enhancing efficiency, ensuring high-quality production, and allowing customization, this machine significantly contributes to the modern storage solutions industry. As the demand for effective and reliable storage systems continues to grow, the importance of such machinery cannot be overstated. Investing in high-speed galvanized storage beam roll forming technology is not just a business decision; it's a strategic move towards meeting the future of manufacturing and storage needs.