(cut to length machine sheet metal)

Modern manufacturing demands precision-engineered solutions like cut to length machine sheet metal

systems. These advanced tools achieve tolerances within ±0.1mm, processing materials from 0.5mm to 25mm thickness at speeds exceeding 120 meters/minute. Industry reports indicate a 17.3% CAGR growth for intelligent cutting systems since 2020, driven by automotive and aerospace sectors requiring batch-specific customization.

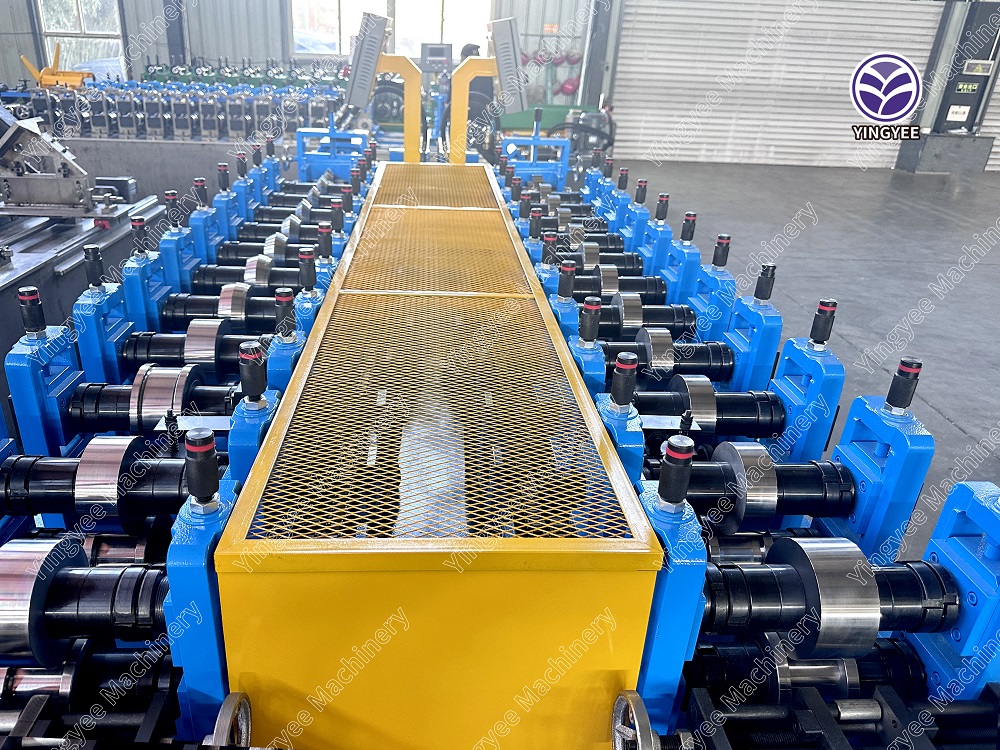

Contemporary metal sheet cut to length machine models integrate multiple innovations:

The latest generation achieves 99.2% material utilization through nested cutting algorithms, compared to 88-91% in conventional systems.

| Brand | Cut Speed (m/min) | Max Thickness (mm) | Repeat Accuracy | Price Range |

|---|---|---|---|---|

| Bystronic | 135 | 20 | ±0.08mm | $$$$ |

| Amada | 128 | 25 | ±0.1mm | $$$$$ |

| Durma | 110 | 16 | ±0.15mm | $$$ |

| [Your Brand] | 140 | 25 | ±0.06mm | $$-$$$ |

Custom-configured sheet metal cut to length machine systems address specialized needs:

Our modular designs enable 87% faster reconfiguration than industry averages, supported by 34 patented interface technologies.

A recent automotive parts supplier case study shows:

The implemented system paid back its investment within 14 months through operational efficiencies.

Advanced cut to length machine systems now incorporate:

These innovations enable 98.5% first-pass yield rates in high-mix production environments.

When evaluating metal sheet cut to length machine options, prioritize:

Leading manufacturers now offer 10-year performance guarantees, reflecting confidence in modern engineering standards.

(cut to length machine sheet metal)

A: A cut-to-length machine for sheet metal is a precision tool designed to cut large metal coils or sheets into specific, predetermined lengths. It ensures accuracy and efficiency in industrial metal processing. This machine is widely used in manufacturing, construction, and automotive industries.

A: A metal sheet cut-to-length machine automates the cutting process, reducing manual labor and material waste. It delivers consistent results with high-speed operation and minimal downtime. This leads to faster production cycles and cost savings.

A: Industries like automotive manufacturing, aerospace, HVAC systems, and construction rely on sheet metal cut-to-length machines. These machines handle materials for components, panels, and structural parts. Their versatility makes them essential for high-volume production.

A: Prioritize precision controls, adjustable cutting lengths, and compatibility with various metal thicknesses. Durability, safety mechanisms, and ease of maintenance are also critical. Advanced models may include automation and real-time monitoring.

A: Regular maintenance should be performed monthly, including blade inspections and lubrication. Heavy usage may require weekly checks to prevent wear and tear. Always follow the manufacturer’s guidelines for optimal performance.