Understanding C Roll Forming Machines A Key Element in Modern Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One of the technologies that has significantly contributed to these goals is the C roll forming machine. This specialized equipment is designed to convert flat metal sheets into C-shaped profiles, commonly used in various industries such as construction, automotive, and furniture manufacturing. This article aims to explore the mechanics, applications, and benefits of C roll forming machines in modern production environments.

What is a C Roll Forming Machine?

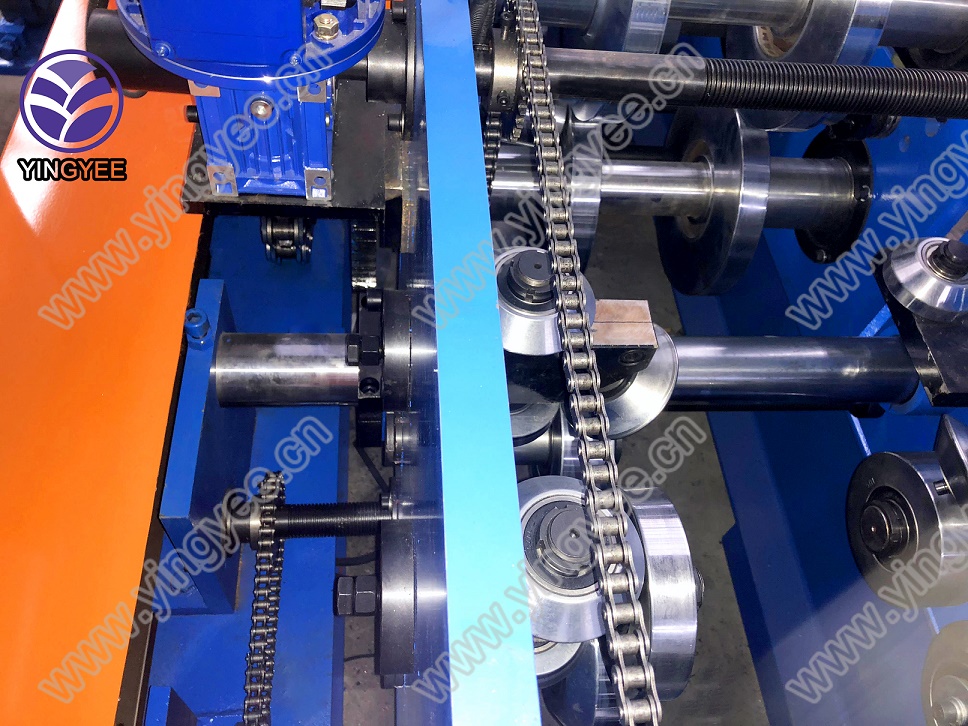

A C roll forming machine is an industrial device utilized to produce consistently shaped C-section profiles by continuously forming metal sheets through a series of rollers. The process begins with the feeding of flat metal sheets into the machine. These sheets are then passed through multiple sets of rollers that progressively shape the material into the desired cross-sectional profile. The machine's design allows it to operate efficiently at high speeds while maintaining tight tolerances, which is essential for quality control in production.

The Process of Roll Forming

The roll forming process is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is gradually shaped into a specific profile. The initial step involves feeding the flat sheet into the roll forming machine. As the metal moves through the machine, it encounters a series of rollers that incrementally bend and shape the material. The number of rollers corresponds to the complexity of the final shape; for C profiles, the process is relatively straightforward, yet it requires precise adjustments to ensure accuracy.

After the metal has been formed into the desired C-shaped profile, it is often cut to length to meet specific requirements. Advanced C roll forming machines are equipped with automatic length cutting systems, which enhance efficiency and reduce material waste. Additionally, some machines can integrate other processes, such as punching holes or adding embossments, further increasing their versatility.

Applications of C Profiles

C-shaped profiles produced by roll forming machines are utilized in a variety of applications. In construction, they are commonly used as framing material for walls, roofs, and floors due to their strength and lightweight properties. The automotive industry utilizes these profiles in the production of structural components, brackets, and supports, emphasizing the importance of precision and strength in vehicle design.

Furthermore, C profiles play a crucial role in furniture manufacturing, particularly in the creation of sturdy frames for desks, chairs, and shelving units. Their adaptability and structural integrity make them ideal for various applications, fostering innovation and design creativity across multiple sectors.

Advantages of C Roll Forming Machines

The adoption of C roll forming machines offers numerous advantages that enhance productivity and reduce costs. One of the primary benefits is the high-speed production capability. As these machines continuously process the metal, manufacturers can produce large quantities of C profiles in a short period, thereby increasing output.

Moreover, roll forming minimizes material waste. The process allows manufacturers to form profiles from flat sheets with less scrap compared to other manufacturing methods. This efficiency is not only environmentally friendly but also contributes to cost savings.

Another significant advantage is the durability and consistency of the produced profiles. The precise engineering of C roll forming machines ensures that every profile meets strict specifications, which is crucial for industries where quality is non-negotiable. Additionally, the machines can easily be adjusted to create different sizes or variations of C profiles without extensive downtime, enhancing flexibility in production.

The Future of C Roll Forming Technology

As industries continue to demand higher production rates and greater accuracy, the technology behind C roll forming machines is expected to evolve. Innovations such as automation, artificial intelligence, and advanced sensors are likely to enhance the capabilities of these machines, making them smarter, faster, and more efficient.

With the ongoing emphasis on sustainability, future C roll forming machines may also focus on reducing energy consumption and waste, aligning with global efforts toward greener manufacturing practices.

In conclusion, C roll forming machines are a vital component of modern manufacturing, providing efficient, precise, and versatile solutions for producing C-shaped profiles. Their application across various industries showcases their importance, while ongoing innovations promise to further enhance their capabilities in the future. As manufacturers continue to seek ways to improve efficiency and reduce costs, C roll forming machines will undoubtedly play a crucial role in shaping the future of production.