The Cold Standing Seam Making Machine An Innovative Solution for Modern Construction

In the world of modern construction and architectural design, the demand for durable, efficient, and aesthetically pleasing building materials is continuously on the rise. One such innovation that has gained significant attention is the cold standing seam making machine. This advanced technology has transformed the way metal roofing systems are manufactured and installed, offering numerous benefits for both contractors and building owners.

Understanding Cold Standing Seam Technology

Cold standing seam roofing systems are characterized by their vertical seams, which are raised and locked together, resembling a series of ridges. This design not only enhances the aesthetic appeal but also provides superior protection against the elements. The seams are typically formed at a right angle to the roof slope, allowing for efficient drainage of rainwater and minimizing the risk of leaks and water intrusion.

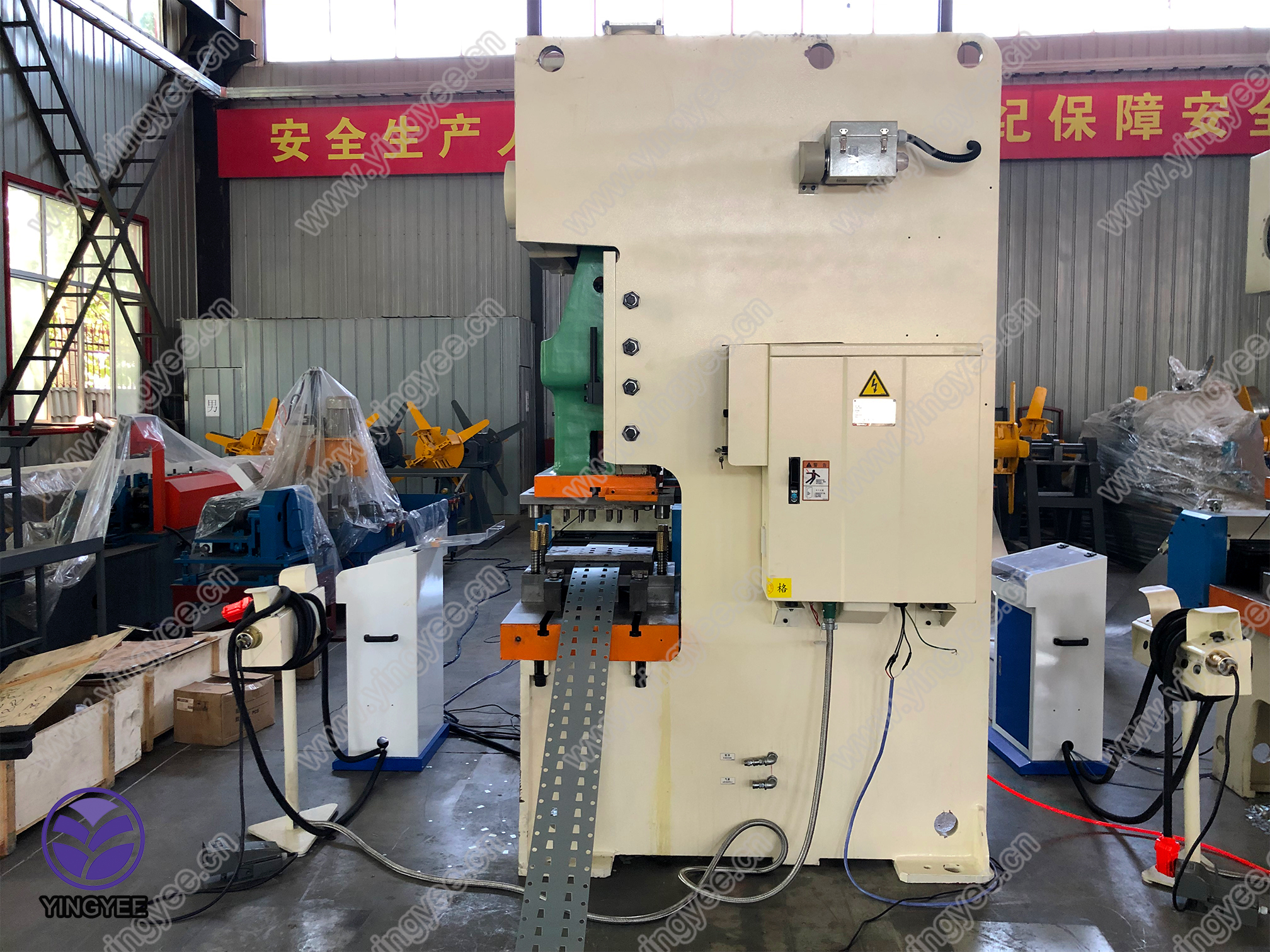

The cold standing seam-making machine automates the process of creating these seams, ensuring precision and consistency in production. This machine operates without the need for heating, which is a significant advantage as it preserves the metal's structural integrity while reducing production costs and energy consumption.

Key Features and Benefits

1. Efficiency and Speed One of the standout features of the cold standing seam-making machine is its speed. The automated system can produce large quantities of seams in a fraction of the time it would take to create them manually. This efficiency allows roofing contractors to complete projects faster, thereby increasing their overall productivity and profitability.

2. Precision Engineering The machine utilizes advanced technology to ensure precise dimensions and consistent quality in every seam produced. This uniformity is crucial for maintaining the aesthetic integrity of the roofing system and ensuring that all components fit perfectly, which minimizes the need for adjustments during installation.

3. Cost-Effectiveness By streamlining the manufacturing process, cold standing seam-making machines help reduce labor costs and material waste. The efficiency of the machine allows contractors to allocate resources more effectively and complete projects within budgetary constraints.

4. Adaptability These machines can be adjusted to accommodate various metal types and thicknesses, including aluminum, steel, and copper. This versatility makes the cold standing seam-making machine suitable for a wide range of applications, from residential homes to commercial buildings.

5. Enhanced Durability The cold forming process used by these machines helps improve the material's overall strength. As the seams are locked into place without the need for additional fasteners, the risk of leaks and structural damage is significantly reduced, providing long-lasting protection for buildings.

Applications in the Construction Industry

Cold standing seam-making machines are increasingly being utilized in various sectors of the construction industry. Their primary application lies in the roofing segment, where they are employed to create durable, weather-resistant roofs that can withstand harsh environmental conditions. In addition to roofing, these machines are also used in the production of metal facades, wall panels, and architectural elements that require precise seam formation.

The rising trend of green building practices has further boosted the adoption of these machines. With their energy-efficient manufacturing process and the use of recyclable materials, cold standing seam roofs align with the sustainability goals of modern construction projects.

Conclusion

The cold standing seam-making machine is a testament to how technology can enhance traditional construction practices. Its efficiency, precision, and adaptability make it an invaluable tool for contractors and builders aiming to meet the evolving demands of the construction sector. As the industry continues to embrace innovative solutions, the cold standing seam-making machine is poised to play a pivotal role in shaping the future of roofing and building design. By investing in this technology, construction professionals can ensure they remain competitive in a rapidly changing marketplace while delivering high-quality results to their clients.