The Importance of Metal Ceiling Stud and Track Systems in Modern Construction

In the realm of modern construction, particularly in commercial and residential building projects, the need for efficient and reliable framing systems is paramount. Among the various framing options available, metal ceiling studs and track systems have emerged as a preferred choice due to their numerous advantages. These systems, often complemented by C-channels, main channels, and wall angles, facilitate the creation of durable and flexible wall and ceiling structures, catering to diverse architectural needs.

Understanding Metal Ceiling Stud and Track Systems

Metal ceiling studs are thin, lightweight sections made from galvanized steel, designed to support drywall and other materials used in ceiling construction. They are typically used in conjunction with track systems, which guide and secure the studs in place. The combination of these elements creates a strong framework that can handle the weight and stress loads imposed by various ceiling materials, including acoustic tiles and plasterboard.

The installation of metal studs and track systems begins with the C-channel sections that serve as the base. C-channels are versatile and can be used for various applications, including wall framing and ceiling support. The C-channel's design provides robust structural integrity, allowing for easy assembly and adjustments during the construction process.

Benefits of Using Metal Studs and Tracks

One of the primary advantages of metal studs is their resistance to environmental factors. Unlike wood, metal does not warp, shrink, or expand with changes in humidity or temperature, making it a reliable choice for diverse climates. Metal systems also have superior fire resistance, which enhances the overall safety of the building. This resilience not only minimizes maintenance costs in the long run but also extends the lifespan of the structure.

In addition to their durability, metal ceiling stud systems are lightweight compared to traditional materials. This feature simplifies transportation, handling, and installation, resulting in time savings for contractors. The precision manufacturing of metal studs means they are typically uniform in size, which helps ensure a straight and level frame, reducing the likelihood of construction errors.

Moreover, metal framing offers flexibility in design and configuration. Whether creating complex ceiling designs in commercial spaces or minimalist walls in residential homes, metal stud systems can be customized to fit various architectural needs. With wall angle sections integrated into the setup, designers can achieve seamless transitions between walls and ceilings, enhancing the overall aesthetics.

Roll Forming Machines Key to Efficient Production

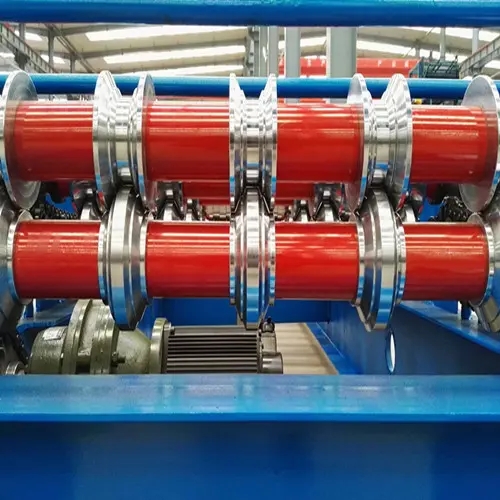

At the heart of metal stud and track production is the roll forming machine, which plays a critical role in crafting these components with precision and efficiency. Roll forming machines shape metal strips into desired profiles through a series of rollers, ensuring consistency and reducing material wastage.

The advanced technology used in these machines allows for the customization of profiles, accommodating specific project requirements. As construction demands evolve, the ability to produce unique shapes and sizes quickly becomes invaluable to manufacturers and builders alike.

Conclusion

In conclusion, metal ceiling stud and track systems represent a dynamic approach to modern construction, offering resilience, flexibility, and efficiency. The integration of C-channels, main channels, and wall angles enhances their functionality, making them suitable for a wide array of applications. With advancements in production technology, such as roll forming machines, the future of metal framing looks promising, paving the way for more innovative and sustainable building practices. As the construction industry continues to evolve, the adoption of metal framing systems will likely increase, ensuring robust and reliable structures for years to come.