Down Pipe Roll Forming Machine A Key Player in Modern Manufacturing

In the realm of modern manufacturing, the efficiency and precision of production processes are paramount. One such innovation that has revolutionized the manufacturing of downpipes is the Down Pipe Roll Forming Machine. This state-of-the-art equipment streamlines the production of downpipes used in various construction and plumbing applications, combining speed, accuracy, and versatility in one efficient system.

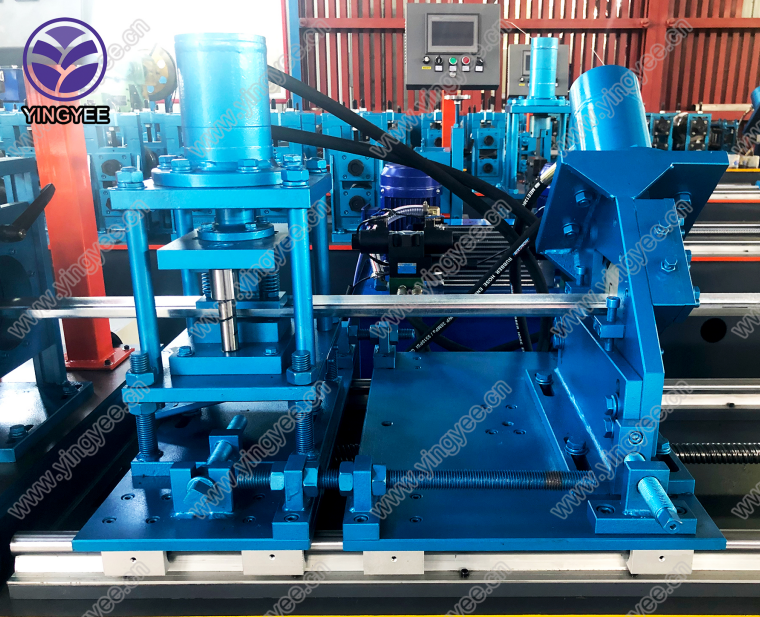

Understanding Down Pipe Roll Forming Machines

A Down Pipe Roll Forming Machine is specifically designed to produce downpipes from metal coils. The process involves feeding a coil of metal, usually galvanized steel or aluminum, into the machine, where it is shaped and cut into specific lengths. The machine consists of several rollers that progressively form the flat material into the desired profile, typically a circular or rectangular section, which is crucial for draining water from roofs and gutters effectively.

The Advantages of Roll Forming Technology

One of the standout features of roll forming technology is its ability to produce long lengths of product continuously. Unlike traditional metal fabrication methods that may involve multiple processes such as cutting, bending, and welding, roll forming is a streamlined method that significantly reduces labor costs and production time. This continuous production not only enhances efficiency but also minimizes material waste, as the process generates fewer off-cuts.

Moreover, the precision with which the Down Pipe Roll Forming Machine operates ensures that every product meets the exact specifications required for installation. This consistency is particularly important in construction, where the fitting of downpipes must be precise to prevent leaks and ensure proper drainage.

Customization and Versatility

Another significant advantage of the Down Pipe Roll Forming Machine is its adaptability. Manufacturers can customize the profiles and dimensions based on the specific requirements of clients or projects. Whether it’s standard sizes or custom shapes, this machinery can handle an array of designs, making it a versatile tool in any metal fabrication shop.

Furthermore, modern Down Pipe Roll Forming Machines are equipped with advanced technology such as PLC (Programmable Logic Controller) systems, which allow for easy programming and adjustments. Operators can swiftly change settings to accommodate different sizes, enhancing the machine's flexibility and reducing downtime.

Sustainability in Manufacturing

In addition to improving efficiency, the use of Down Pipe Roll Forming Machines aligns with sustainable manufacturing practices. By minimizing waste and optimizing material usage, manufacturers can significantly reduce their environmental footprint. As businesses increasingly focus on sustainability, investing in such machinery not only boosts productivity but also demonstrates a commitment to eco-friendly practices.

Conclusion

In conclusion, the Down Pipe Roll Forming Machine stands as a pillar of modern manufacturing, specifically in the production of downpipes. With its ability to produce high volumes of precise, custom-designed products while minimizing waste and labor costs, it is an invaluable asset for manufacturers in the construction and plumbing industries. As technology continues to advance, the importance of such machinery in promoting efficiency and sustainability will only grow, making it a critical component of future manufacturing strategies. The integration of Down Pipe Roll Forming Machines into production lines is a testament to innovation and responsiveness in an ever-evolving marketplace.