Understanding Cable Tray Bending Machines Innovations and Applications

Cable tray bending machines have become indispensable in various industries, particularly in electrical installations, telecommunications, and construction. They are specialized tools designed to bend cable trays—metal channels used for supporting insulated electrical cables, which are essential for managing cables in a safe and organized manner. The importance of these machines lies in their ability to facilitate the efficient installation and management of cable systems, ultimately contributing to the overall safety and functionality of electrical networks.

What is a Cable Tray?

Before delving into the specifics of cable tray bending machines, it's essential to understand what cable trays are. A cable tray is a system used to support insulated electrical cables and can be used in both commercial and industrial settings. They come in various forms, including ladder, ventilated, and solid-bottom types, and are constructed from materials such as aluminum, steel, or fiberglass. These trays protect cables from environmental hazards, provide excellent air circulation to manage heat, and enable easy access for maintenance and modifications.

The Role of Cable Tray Bending Machines

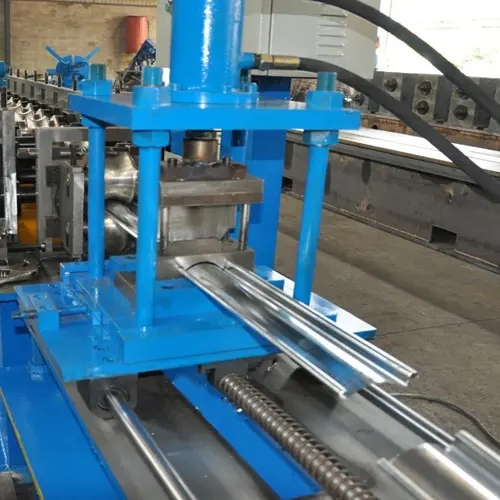

Cable tray bending machines are specifically designed to help create the necessary angles and curves in cable trays, which is crucial for fitting them into building structures and connecting them efficiently to electrical distribution systems. The bending process not only simplifies the installation process but also minimizes the risk of cable damage that might occur during transport or installation.

These machines are equipped with advanced technology that can produce precise bends based on predetermined specifications. The user's ability to create intricate layouts can lead to more organized wiring systems, reducing clutter and enhancing safety within electrical installations.

Types of Cable Tray Bending Machines

1. Manual Bending Machines These are often used for smaller-scale projects and generally require more physical labor. While they may not offer the precision of automated machines, they are cost-effective and suitable for basic bending tasks.

2. Hydraulic Bending Machines Utilizing hydraulic power, these machines allow for a high degree of precision and the ability to bend multiple trays quickly. They are essential for larger projects that require consistent results and efficiency.

3. CNC Bending Machines Computer Numerical Control (CNC) machines represent the pinnacle of cable tray bending technology. These machines are programmed to perform complex bending operations automatically. They offer high precision and allow for the repeatability needed for large-scale production.

Advantages of Using Cable Tray Bending Machines

1. Increased Efficiency Automated bending machines significantly reduce the time required for bending trays, thus speeding up the installation process. This is particularly beneficial in projects with tight deadlines.

2. Cost-Effectiveness While the upfront cost of sophisticated machines like CNC benders can be high, they can lead to substantial savings in the long run. Reduced labor costs and minimized material waste contribute to overall project savings.

3. Precision and Consistency One of the main advantages of using bending machines is the precision they provide. Accurate bends help ensure that cable trays fit perfectly into their designated spaces, which is critical for maintaining organization and safety.

4. Improved Safety Properly installed cable trays reduce the risk of accidents related to cable damage or disorganization. Cable tray bending machines help ensure that every bend is made according to specifications, which increases the safety of electrical installations.

Conclusion

Cable tray bending machines represent a vital aspect of modern electrical installations and infrastructure development. Their role in creating organized, safe, and efficient cable systems cannot be overstated. As technology continues to evolve, the capabilities of these bending machines are also expected to advance, further enhancing their efficiency, precision, and user-friendliness. For businesses involved in electrical installation and management, investing in a quality cable tray bending machine can lead to improved operational efficiency, cost savings, and enhanced safety in their electrical networks. Whether you are involved in a small project or a large-scale operation, the advantages brought by these machines are significant, paving the way for a more organized and reliable electrical system.