A roller shutter door forming machine is an essential asset in the industrial machinery sector, revolutionizing how manufacturers approach door production. With advancing technology and innovative design, these machines enhance the efficiency and quality of roller shutter doors, which are crucial for securing both commercial and residential properties. Investing in this machine not only improves production efficiency but also elevates product quality, making it an indispensable tool for manufacturers.

A vital aspect of understanding these machines lies in their expert manufacturing process.

Roller shutter door forming machines are designed with precision engineering, which ensures that each door produced meets stringent quality standards. The machine's ability to produce seamless sections from premium-grade materials gives companies an edge in the competitive market by enabling them to deliver products that boast durability and aesthetic appeal. Furthermore, manufacturers can customize machines to produce various designs and finishes, complying with customer demand and industry standards.

The expertise involved in the operation of roller shutter door forming machines is critical. Operators need comprehensive training to manage the advanced technology these machines employ. Such training typically covers machine setup, troubleshooting, maintenance, and safety protocols. Proper training not only enhances operational efficiency but also minimizes downtime, ensuring a smooth production line and consistent product output.

Authoritativeness in roller shutter door forming machines can be attributed to the manufacturers who have invested heavily in research and development. These companies prioritize continuous improvement by integrating the latest technological advancements into their products. They provide end-users with detailed user manuals, robust customer support, and ongoing updates for software and hardware. As a result, these manufacturers maintain an authoritative presence in the industry, offering products that consistently outperform competitors in function, reliability, and innovation.

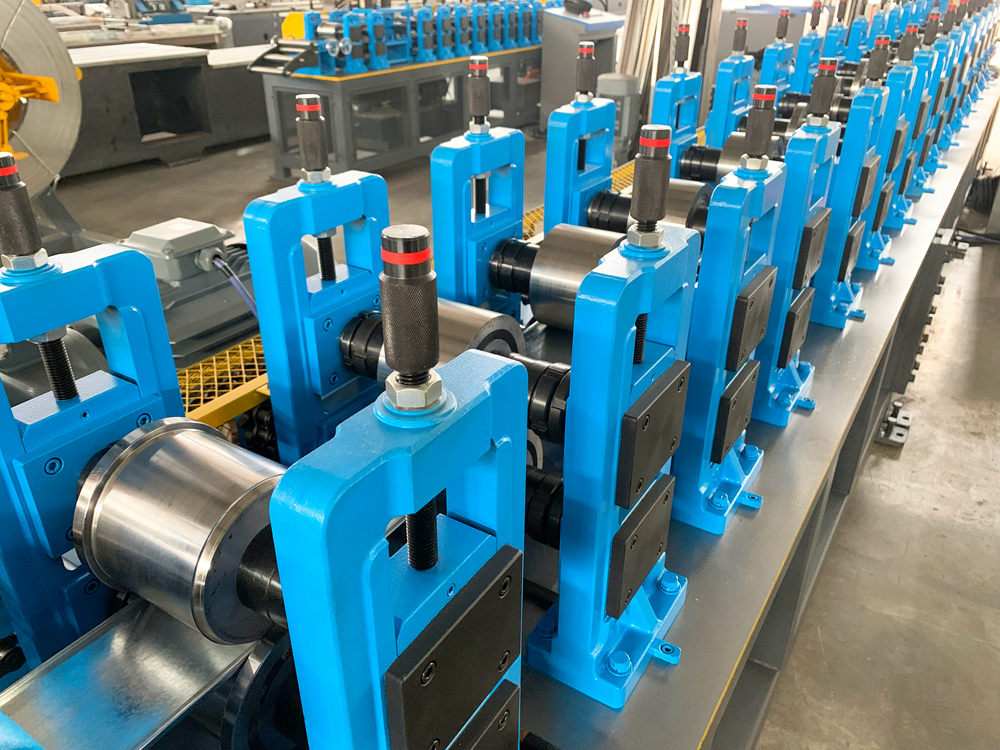

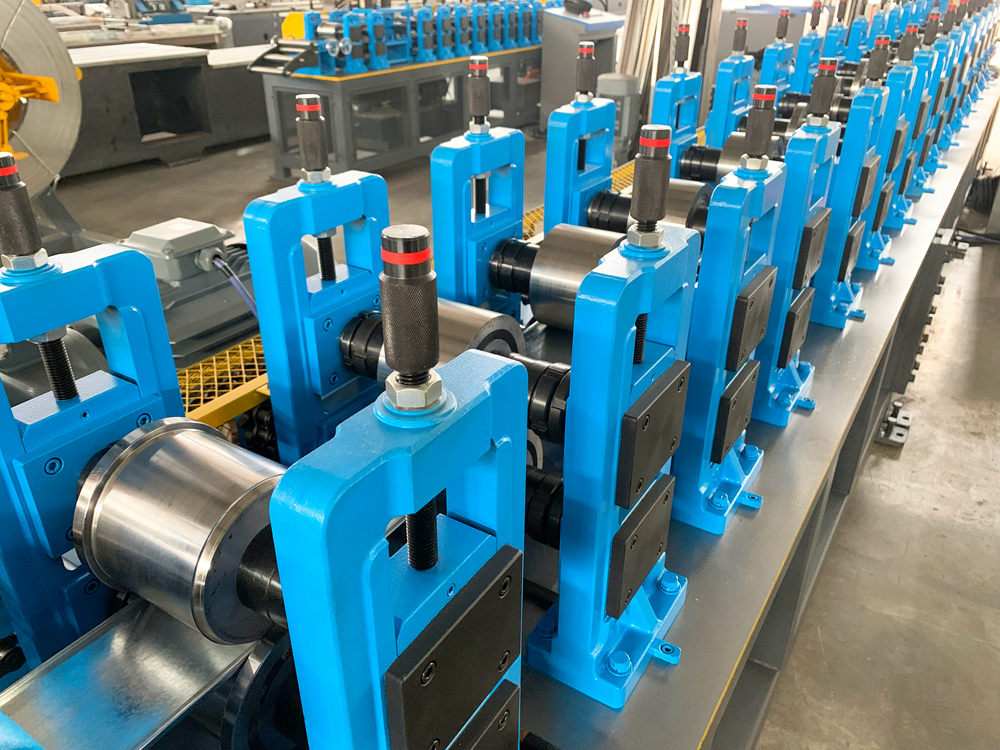

roller shutter door forming machine

The trustworthiness of a roller shutter door forming machine is largely based on the reputation of its manufacturer and the experiences of past users. Customer reviews and testimonials serve as a valuable resource for potential buyers, offering insights into the machine's performance and reliability in real-world applications. Proven track records and endorsements from recognized industry players also enhance a product’s credibility. Additionally, trusted manufacturers often provide warranties and service packages, ensuring that buyers feel confident in their purchase.

Productivity is significantly enhanced by a roller shutter door forming machine’s sophisticated automation features. By reducing manual labor and speeding up the manufacturing process, these machines allow companies to meet high production demands without compromising on quality. The automation features integrated into these machines lead to efficient resource utilization, optimizing materials usage and energy consumption, which not only lowers operational costs but also supports sustainable manufacturing practices.

Embracing modern technology, roller shutter door forming machines also offer compatibility with digital input and customization tools, allowing production to be tailored to exact specifications. This adaptability to different design requirements and the potential to incorporate new materials mean that markets can be expanded quickly, with the capacity to deliver diverse products to global clients.

In conclusion, roller shutter door forming machines symbolize a blend of expertise, innovation, and reliability, essential to the modern manufacturing landscape. By choosing the right machine, businesses can secure a competitive advantage, driven by increased efficiency, precise quality control, and an unmatched ability to meet evolving market needs. With ongoing technological advancements and a firm commitment to quality, these machines remain at the forefront of industrial automation and production excellence.