The Role of Cold Bending Machines in Manufacturing Noise Barriers

In recent years, the increasing emphasis on environmental protection and noise pollution control has paved the way for innovative solutions in urban and industrial settings. One of the key components in addressing noise pollution is the construction of effective noise barriers. These structures help to mitigate sound propagation from highways, railways, and construction sites, allowing communities to enjoy a peaceful environment. A crucial piece of equipment in the manufacturing of these noise barriers is the cold bending machine, an essential tool in creating durable and efficient noise reduction panels.

Understanding Cold Bending Technology

Cold bending technology refers to the process of shaping materials, particularly metals, at room temperature. This technique is instrumental in producing various components needed for noise barriers, such as steel or aluminum panels. Unlike hot bending processes, which can alter the material properties through thermal exposure, cold bending maintains the integrity of the metal while allowing for precise manufacturing. The result is a high-quality product that can withstand external elements, including extreme weather conditions, without compromising structural integrity.

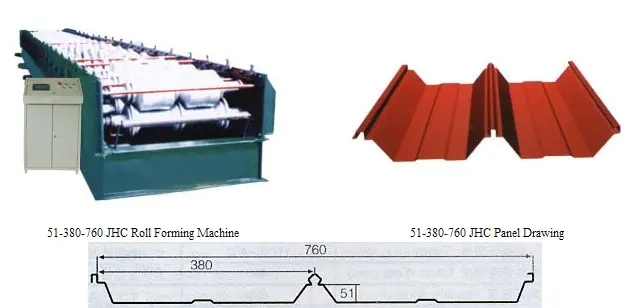

Key Features of Cold Bending Machines

Cold bending machines are designed with versatility and precision in mind. They come equipped with advanced features that allow operators to adjust bending angles and radii, ensuring that each component meets specific design requirements. These machines often utilize computer numerical control (CNC) technology, which enhances accuracy and repeatability, thereby reducing the likelihood of errors during production. Furthermore, many modern cold bending machines can handle various materials and thicknesses, making them ideal for manufacturers producing noise barriers in differing specifications.

The Benefits of Cold Bending in Noise Barrier Production

The advantages of using cold bending machines in the production of noise barriers are manifold

1. Durability and Strength Cold bending processes enhance the tensile strength of metals, which is crucial for the longevity of noise barriers. These structures need to endure not only the pressure of high winds and impacts but also the vibrations caused by passing vehicles.

2. Design Flexibility Cold bending machines allow for complex shapes and designs, enabling manufacturers to create customized noise barriers tailored to specific site requirements. This flexibility is particularly important in urban environments where architectural aesthetics must be considered.

3. Cost Efficiency By streamlining the manufacturing process and reducing waste material, cold bending machines contribute to lower production costs. The efficiency of these machines also allows for faster production times, helping to meet project deadlines without sacrificing quality.

4. Environmental Considerations Manufacturers can produce noise barriers that are not only effective in sound reduction but are also made from recyclable materials. Cold bending technology, combined with eco-friendly materials, aids in the creation of sustainable urban structures.

5. Enhanced Sound Insulation When combined with acoustic materials, cold-bent panels can significantly reduce sound transmission. This makes them highly effective for use in residential areas located near busy roads or industrial zones.

Conclusion

As urbanization continues to rise, the demand for effective noise control solutions will grow correspondingly. Cold bending machines play a pivotal role in the manufacturing of noise barriers, providing the strength, flexibility, and efficiency necessary to produce high-quality products. By incorporating these advanced technologies, manufacturers can meet the challenges posed by noise pollution while contributing to a more sustainable and aesthetically pleasing urban environment. The combination of innovative manufacturing processes and sound-reducing structures marks a significant step forward in noise management, ultimately leading to better living conditions for countless communities around the world.