The Advantages of Metal Stud Roll Forming Machines with Consistent Length and No Twist

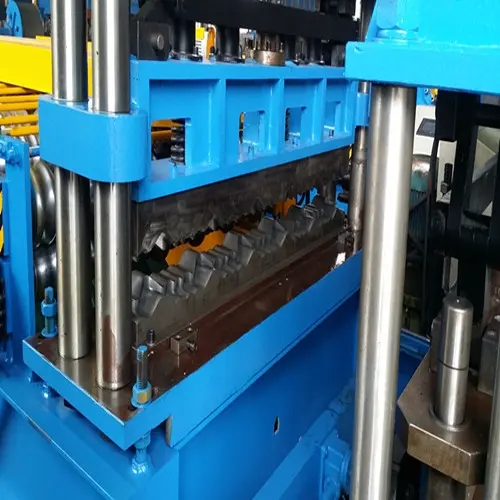

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the most remarkable innovations contributing to these goals is the metal stud roll forming machine. These machines are specially designed to produce metal studs used in various applications, including framing for walls, ceilings, and partitions. In this article, we will explore the benefits of using metal stud roll forming machines that guarantee consistent lengths and a twist-free output.

First and foremost, the need for consistency in manufacturing cannot be overstated. Traditional methods of producing metal studs often resulted in variability in length and shape. Such inconsistencies can lead to significant issues during the assembly process, leading to wasted materials and increased labor costs. Metal stud roll forming machines address this challenge effectively. These machines are programmed to produce studs of predetermined lengths with utmost accuracy. The precision engineering ensures that every stud generated meets the exact specifications required for a project, ultimately enhancing overall quality.

Moreover, the twist-free characteristic of these machines is a game-changer in the industry. In traditional manufacturing setups, metal studs may experience warping or twisting during the production process, adversely affecting their structural integrity. A twisted stud can compromise the stability of an entire frame, leading to costly repairs or even safety hazards. Metal stud roll forming machines mitigate this risk by employing sophisticated design and technology that maintains the linearity of the studs throughout the forming process. As a result, builders can trust that the materials they are working with will perform as expected under load, ensuring the long-term durability of structures.

Another significant benefit of metal stud roll forming machines is their efficiency in production. The continuous form and cut capabilities allow for rapid manufacturing without the need for manual intervention, which can slow down processes and introduce human error. With automated systems, builders can produce large quantities of studs in a relatively short period, streamlining project timelines and enhancing productivity. This efficiency not only saves time but also reduces labor costs, making it a financially sound investment for construction companies.

Additionally, the versatility of metal stud roll forming machines means they can accommodate various materials, including steel and aluminum. This flexibility allows builders to select the best materials for their specific project needs, whether it’s lightweight aluminum for easy handling or robust steel for maximum strength. The adaptability of these machines to different materials also means that they can meet a diverse range of construction standards and client requirements.

Moreover, investing in metal stud roll forming machines with no twist and consistent length contributes to sustainability in construction. By minimizing waste through precise cutting and reducing the need for adjustments during installation, companies can significantly lower their overall material consumption. This approach not only helps to protect the environment but also aligns with the growing demand for sustainability in the construction industry.

In conclusion, the integration of metal stud roll forming machines that offer consistent lengths and a twist-free output represents a significant advancement in construction technology. Their precision, efficiency, and versatility make them an invaluable asset for builders looking to improve quality and productivity. As the industry continues to evolve, embracing innovations like these will be crucial for meeting the demands of modern construction while ensuring safety and sustainability. Investing in such machines is not just a choice; it’s a strategic step towards a more efficient and reliable future in construction.