The Evolution and Importance of Galvanized Deck Floor Roll Forming Machines

In the modern construction industry, efficiency and durability are paramount. One of the innovative solutions that has emerged to meet these demands is the galvanized deck floor roll forming machine. This technology provides an effective method for producing high-quality metal decking, which is critical for various construction applications, including commercial buildings, warehouses, and residential structures.

A galvanized deck floor is made from steel that is coated with a layer of zinc, resulting in enhanced corrosion resistance and increased longevity. The galvanization process not only protects the steel but also provides an aesthetically appealing finish that can withstand harsh environmental conditions. As a result, the demand for galvanized deck flooring has risen significantly, leading to a corresponding need for advanced manufacturing equipment to produce these materials efficiently.

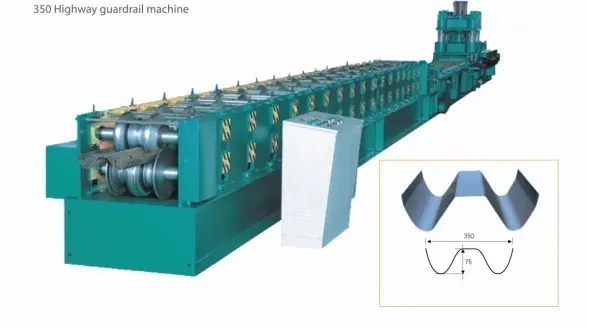

Roll forming machines play a crucial role in this production process. They operate by feeding a coil of steel through a series of rollers that gradually shape the metal into the desired profile. This continuous forming process allows for the production of long lengths of decking with minimal waste, making it an economically viable option for manufacturers. Additionally, the precision of roll forming ensures that each deck piece has uniform dimensions, which is essential for structural integrity.

Investing in a galvanized deck floor roll forming machine offers numerous benefits. Firstly, these machines can operate at high speeds, significantly increasing production capacity. This efficiency translates to lower labor costs and faster delivery times for construction projects. Furthermore, the quality of the finished product is enhanced, as the roll forming process minimizes the risk of defects commonly associated with other manufacturing techniques.

Another advantage is the versatility of roll forming machines. They can be customized to produce different profiles based on specific project requirements. This adaptability allows manufacturers to cater to a diverse range of clients, whether they require lightweight panels for residential buildings or heavier-duty decking for commercial applications.

Sustainability is another key consideration in today’s construction industry. Galvanized steel is highly recyclable, making it an environmentally friendly choice. By utilizing roll forming technology, manufacturers can optimize the use of raw materials and minimize waste, contributing to a more sustainable production process.

In summary, the galvanized deck floor roll forming machine represents a significant advancement in the construction industry. It not only enhances the efficiency and quality of metal decking production but also aligns with sustainability goals. As construction projects continue to evolve, the reliance on such state-of-the-art manufacturing equipment will likely grow, ensuring that builders can meet the demands of both safety and performance. Embracing these innovations is essential for companies looking to stay competitive in a rapidly changing market, and the galvanized deck floor roll forming machine stands at the forefront of this transformation.