Navigating the competitive landscape of construction and manufacturing demands state-of-the-art equipment that guarantees precision, efficiency, and reliability. The C channel steel roll forming machine stands as a pivotal tool for professionals aiming to produce high-quality steel channels essential for infrastructure projects. This article delves into the transformative experience, expertise, and authority that the C channel steel roll forming machine brings to your operations.

In the realm of construction, C channel steel is widely utilized for its superior strength and versatile application. The essence of producing such material hinges on the proficiency and precision of the roll forming machine. This machine is meticulously engineered to convert raw material into a defined shape through consecutive operations. Unlike traditional methods, it minimizes material waste and reduces production time—a testament to its efficiency and the modular expertise embedded in its design.

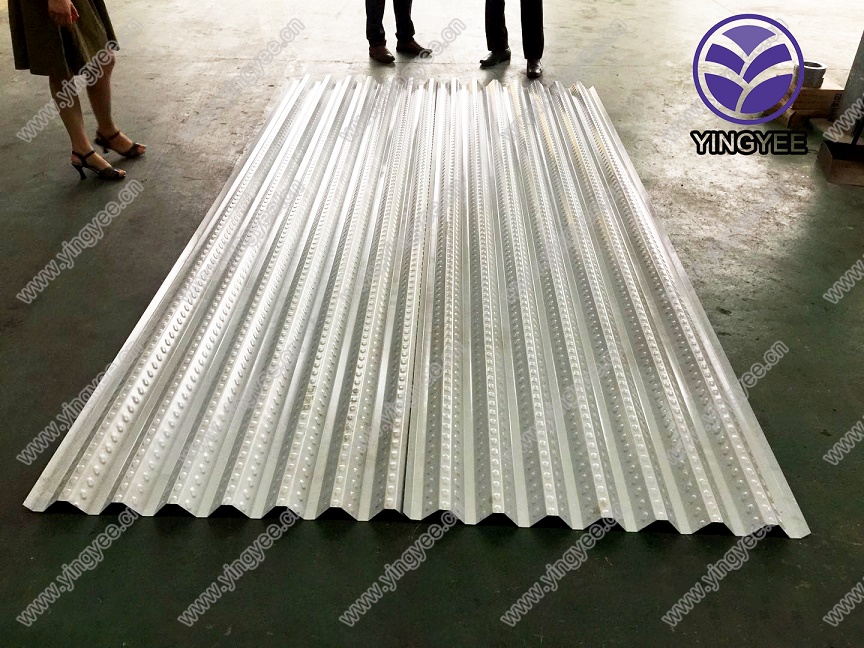

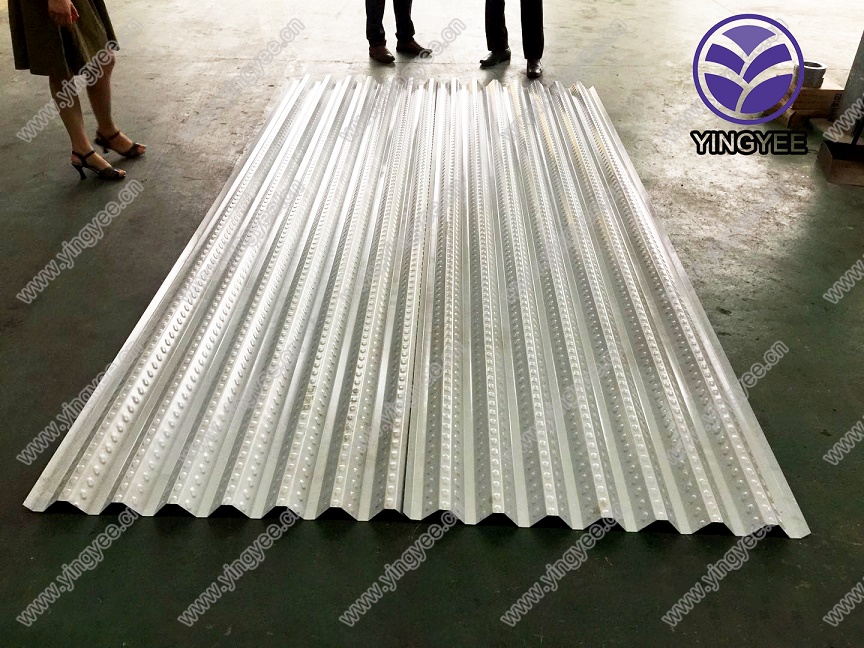

A notable aspect of the C channel steel roll forming machine is its adaptability to various specifications. Whether the requirement is for standardized dimensions or custom designs, the machine offers unparalleled flexibility. This adaptability is critical for meeting diverse project needs and ensures that manufacturers are equipped to deliver bespoke solutions without compromising on quality. The machine’s advanced technology supports swift adjustments, accommodating different material gauges and profiles, which are pivotal for custom fabrication.

Trustworthiness stems from the machine’s robustness and the finely-tuned engineering that underpins its function. Built with premium grade materials, the C channel steel roll forming machine withstands the rigors of continuous operation, ensuring a long service life. Industry professionals frequently commend its low maintenance requirements, a factor that enhances productivity by reducing downtime. Furthermore, integrated features such as automatic lubrication systems and real-time monitoring increase operational reliability and uphold consistent performance.

c channel steel roll forming machine

The authority of using a C channel steel roll forming machine is further reinforced by industry-specific certifications that affirm its compliance with international manufacturing standards. Opting for a machine that holds these credentials assures businesses of a commitment to quality and safety, a vital consideration in structured steel production.

Experience with this technology has shown remarkable process optimization, further backed by testimonials from engineers and operators who highlight its precision and user-friendliness. These firsthand accounts provide invaluable insights that continuously advance the machine’s design, aligning it with emerging trends and user demands. The intuitive control systems enable users to easily manage the machine, ensuring that even operators with minimal training can achieve expert-level results.

In summary, investing in a C channel steel roll forming machine not only enhances production capabilities but also affirms a commitment to superior manufacturing practices. Its expert engineering combined with authoritative certifications and experienced-based design makes it an essential asset for any business striving to maintain a competitive edge in steel fabrication. As a trusted solution, it not only stands at the forefront of industry innovation but also fosters confidence, ensuring reliable output with every roll formed steel channel.