The Emerging Trend of Aluminum Roof Tile Making Machines

In today's construction and manufacturing industries, innovation is key to meeting evolving demands for quality and efficiency. One area that has seen significant advancement is the production of roof tiles, particularly through the use of aluminum roof tile making machines. This machinery offers an array of benefits, making it a preferred choice for manufacturers worldwide.

Aluminum has long been recognized for its durability, lightweight nature, and resistance to corrosion, making it an excellent material for roof tiles. Unlike traditional materials such as clay or concrete, aluminum provides longevity and requires minimal maintenance. This is especially valuable in regions experiencing extreme weather conditions, where roof integrity is paramount.

The advent of aluminum roof tile making machines has revolutionized how these tiles are produced. These machines are designed to automate the entire process, significantly reducing the labor required and increasing production speed. The automation not only enhances efficiency but also ensures consistency in quality across batches. This is essential for meeting the stringent requirements of the construction industry, where material failure can lead to serious consequences.

One standout feature of aluminum roof tile making machines is their ability to produce tiles in various shapes and styles. From traditional designs that mimic the look of clay tiles to modern, sleek profiles, manufacturers can cater to diverse architectural demands. This flexibility in design allows builders and homeowners to choose tiles that complement their aesthetic preferences while benefiting from the inherent advantages of aluminum.

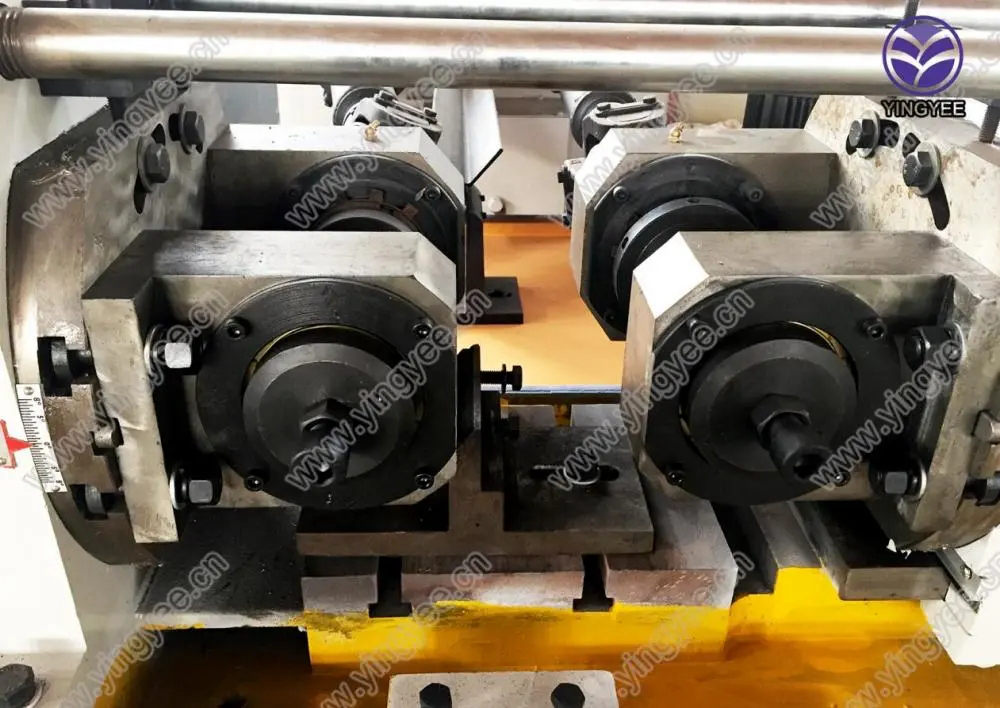

Moreover, these machines are equipped with advanced technology that enhances the precision of tile production. Features such as computer numerical control (CNC) ensure that tiles are cut and shaped with exceptional accuracy, minimizing waste and maximizing efficiency. This technological integration not only improves product quality but also contributes to a more sustainable manufacturing process by reducing the consumption of raw materials.

The environmental benefits of using aluminum roof tiles are also noteworthy. Aluminum is recyclable, which means that at the end of its life cycle, it can be repurposed rather than ending up in landfills. This characteristic aligns with the growing emphasis on sustainability in construction, as more developers seek green building materials that support eco-friendly practices.

Investing in aluminum roof tile making machines can lead to significant cost savings for manufacturers. The initial investment may be substantial, but the long-term benefits in terms of reduced labor costs, lower maintenance, and increased durability of the final product can outweigh the upfront expenditure. Companies can also find themselves more competitive in the marketplace, as they are able to offer superior products that meet modern standards for quality and sustainability.

In conclusion, the aluminum roof tile making machine represents a significant advancement in the construction industry. By automating the production process and utilizing the advantages of aluminum, manufacturers can produce high-quality, sustainable roofing solutions that meet the diverse needs of the market. With the ongoing push for innovation and efficiency, these machines are set to play an increasingly vital role in the future of roofing materials. As demand for durable and environmentally friendly building solutions continues to grow, it is clear that aluminum roof tile production is an area ripe for exploration and investment.