The Importance of Steel Rebar Mesh Welding Machines in Construction

In the construction industry, the demand for strong and durable reinforcement materials is ever-increasing. Steel rebar, or reinforcing bar, is essential for providing the tensile strength necessary to support concrete structures, enhancing stability and longevity. Among the various technologies employed in manufacturing rebar, steel rebar mesh welding machines play a critical role. These machines automate the welding process for steel mesh, significantly improving efficiency and precision in construction projects.

Understanding Steel Rebar Mesh

Steel rebar mesh consists of a grid of both horizontal and vertical steel bars welded together at their intersections. This mesh is typically used to reinforce concrete slabs, walls, and other structural elements. By distributing loads more evenly, rebar mesh mitigates the risk of cracking and structural failure, making it a vital component in modern construction practices. The assembly of rebar meshes can be time-consuming and labor-intensive if done manually, which is where welding machines come into play.

The Functionality of Welding Machines

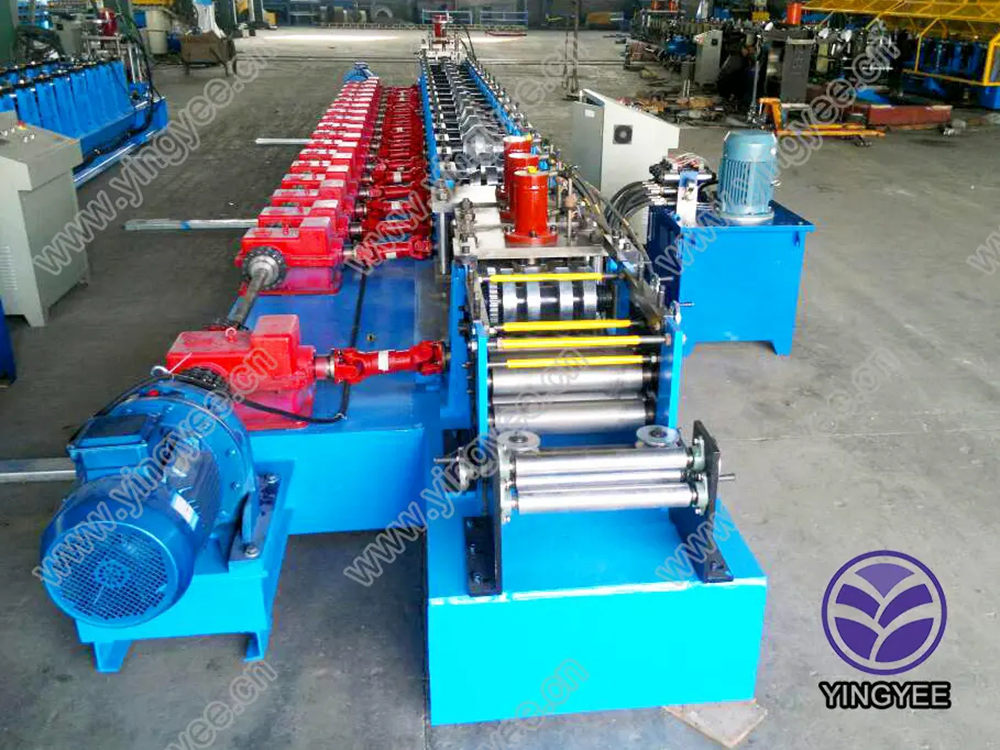

Steel rebar mesh welding machines are designed to automate the welding process, offering a range of advantages over manual methods. These machines can produce large amounts of rebar mesh in a fraction of the time, ensuring rapid production rates that meet the demands of construction schedules. Automated welding not only increases productivity but also enhances the quality and consistency of the welded joints, resulting in a more reliable reinforcement product.

One popular type of welding machine is the automated mesh welding machine, which can adjust to various sizes and configurations of rebar mesh. This versatility allows manufacturers to cater to specific project requirements without undergoing extensive reconfiguration or downtime, thus optimizing production efficiency.

Increased Efficiency and Cost Savings

Using steel rebar mesh welding machines leads to significant cost savings in several ways. Firstly, the reduced labor costs associated with automating the welding process can lead to lower overall production expenses. Additionally, the increased speed of production means that projects can be completed more quickly, allowing for faster turnover rates and the ability to take on more contracts.

Secondly, the precision offered by these machines minimizes material waste. When bars are welded together accurately, the final product is more uniform, and excess material is not needed. This reduction in waste not only benefits the budget but also contributes to environmental sustainability efforts within the construction industry.

Quality Control and Safety

Quality control is essential in construction, as structural integrity directly impacts the safety of buildings and infrastructure. Steel rebar mesh welding machines feature advanced monitoring systems that ensure each weld meets specific quality standards. Automated systems can detect inconsistencies, alerting operators before defective meshes are released for construction use.

Moreover, automating the welding process reduces the risk of workplace injuries associated with manual welding, such as burns or repetitive strain injuries. The machine effectively handles the welding tasks, allowing human workers to focus on other aspects of production or oversight.

Conclusion

The integration of steel rebar mesh welding machines in the construction sector represents a significant advancement in building technology. By automating the welding process, these machines provide increased efficiency, consistency, and cost-effectiveness, which are crucial in today's fast-paced construction environment. As the industry continues to evolve, investing in advanced welding technology will be essential for companies looking to maintain a competitive edge, enhance safety, and ensure high-quality structural integrity in their projects.

In summary, the evolution and adoption of steel rebar mesh welding machines are not only revolutionizing the way rebar is processed but also helping to define the future of construction practices. With their ability to produce high-quality materials quickly and safely, these machines are setting new standards and playing a vital role in building resilient infrastructures for the future.