The Evolution of Roofing Tile Forming Machines

The construction industry has seen a significant evolution over the years, driven by advancements in technology, materials, and manufacturing processes. One of the essential components in this evolution has been the roofing tile forming machine. These innovative machines have transformed the production of roofing tiles, making it faster, more efficient, and more sustainable.

Understanding Roofing Tile Forming Machines

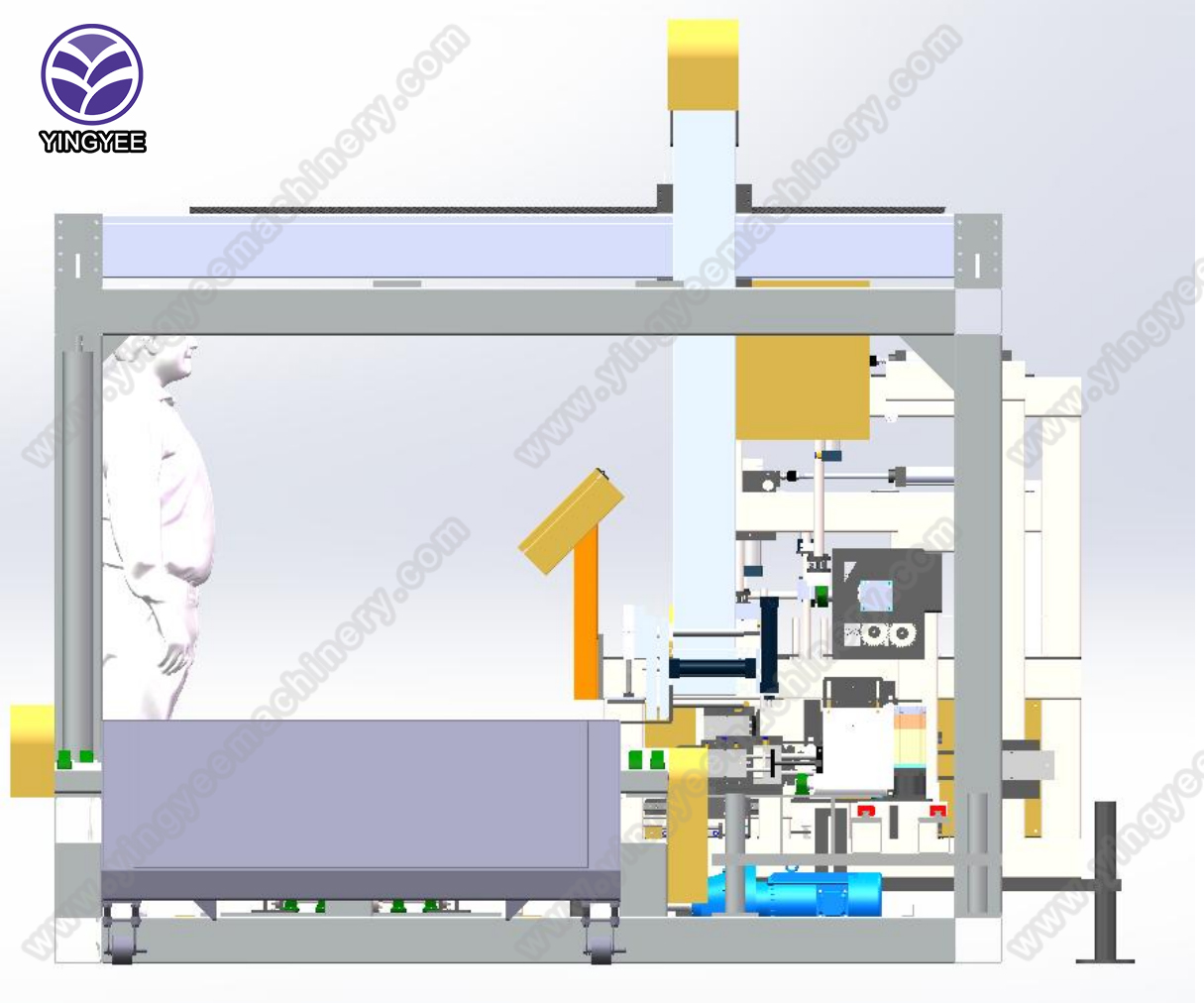

Roofing tile forming machines are specialized equipment designed to produce roofing tiles in various shapes, sizes, and materials. These machines can work with materials such as ceramic, concrete, metal, and polymer, enabling manufacturers to cater to a broader market demand. The production process generally involves feeding raw materials into the machine, which then forms, shapes, and curtails the tiles to a precise specification.

The Production Process

The production process begins with the selection and preparation of raw materials. For instance, in the case of concrete tiles, cement, sand, and additives are mixed to create a homogenous blend. This mixture is then fed into the roofing tile forming machine, which uses a series of rollers and dies to shape the mixture into tiles. The process can vary slightly depending on the type of machine being used, but the fundamental steps remain largely consistent.

After the tiles are formed, they undergo a curing process to enhance their strength and durability. This usually involves drying the tiles at controlled temperatures and humidity levels. Finally, the finished tiles are tested for quality assurance to ensure they meet industry standards before being packaged and shipped.

Advantages of Roofing Tile Forming Machines

The advent of roofing tile forming machines has brought about numerous advantages to manufacturers and the construction industry as a whole. Here are some key benefits

1. Efficiency and Speed Modern roofing tile forming machines can produce a high volume of tiles in a short period. This increased efficiency allows manufacturers to meet the growing demand for roofing materials without compromising quality.

2. Customization These machines offer a range of customization options, enabling manufacturers to produce tiles in various designs, colors, and textures. This flexibility caters to the diverse aesthetic preferences of homeowners and builders.

3. Cost-Effectiveness By automating the production process, roofing tile forming machines significantly reduce labor costs and minimize material waste. This translates into cost savings for manufacturers, which can be passed on to consumers.

4. Sustainability Modern machines often incorporate technologies aimed at reducing energy consumption and minimizing waste generation. Some machines can even utilize recycled materials, contributing to more sustainable manufacturing practices.

Innovations in Technology

Technological advancements continue to shape the capabilities of roofing tile forming machines. For instance, the integration of automation and robotics has enhanced precision and repeatability in tile manufacturing. Moreover, Computer Numerical Control (CNC) technology allows for intricate designs and patterns that were previously difficult to achieve.

Additionally, the rise of smart manufacturing and Industry 4.0 means that roofing tile forming machines can now be connected to the Internet, enabling real-time monitoring and data analysis. This connectivity helps manufacturers optimize production schedules, predict maintenance needs, and improve overall efficiency.

Future Trends

As the construction industry moves towards more sustainable practices, roofing tile forming machines will continue to evolve. This includes the development of machines that can utilize alternative materials, such as bio-based composites or even waste products, to produce roofing tiles. Furthermore, the emphasis on energy efficiency will likely lead to innovations in machine design and operation, ensuring that production methods align with global sustainability goals.

Conclusion

The roofing tile forming machine represents a critical advancement in construction technology, combining efficiency, customization, sustainability, and innovation. As the industry continues to evolve, these machines will play an essential role in shaping the future of roofing material production, paving the way for smarter, more sustainable construction practices. With ongoing advancements in technology and an increasing focus on environmental impact, the roofing tile forming machine is set to remain a cornerstone of the construction industry for years to come.