The Future of Cable Management Galvanized Steel Cable Tray Roll Forming Machines

In today's rapidly evolving world of industrial automation and construction, the need for efficient, durable, and dependable cable management systems is paramount. One of the most innovative solutions to this need is the galvanized steel cable tray roll forming machine. These advanced machines not only streamline the production of cable trays but also ensure quality, sustainability, and cost-effectiveness in cable management.

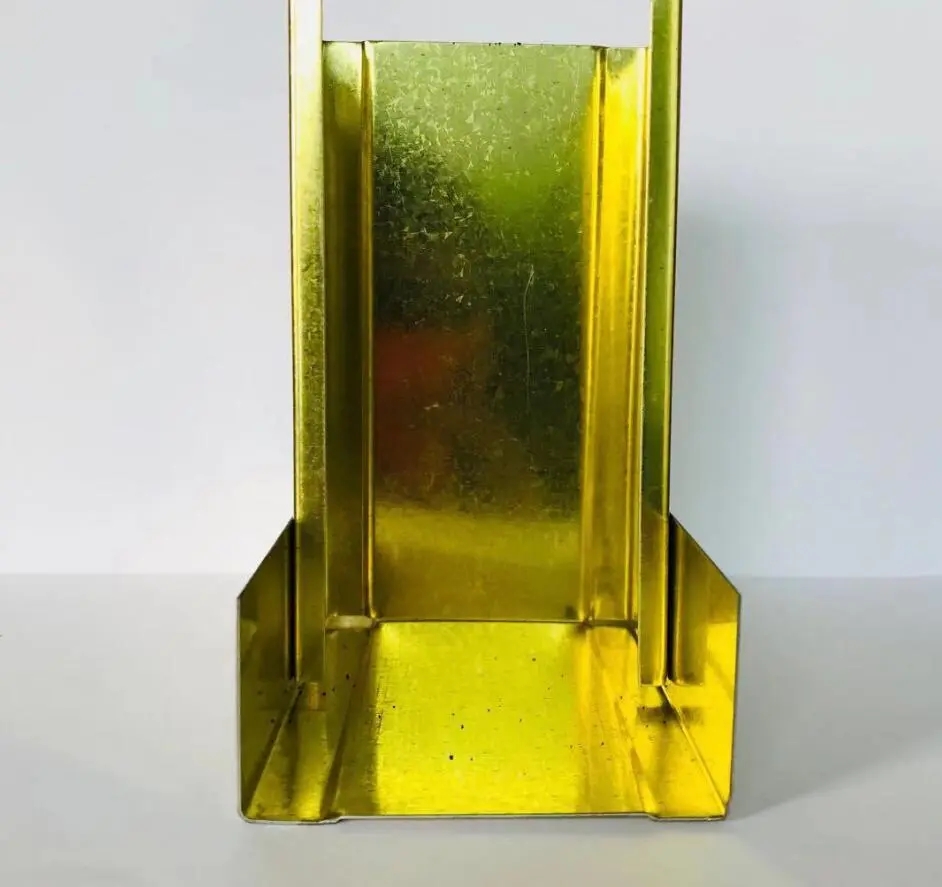

Understanding Cable Trays

Cable trays serve as an essential infrastructure for managing electrical wiring in buildings, industries, and plants. They provide organized pathways for electrical cables, which helps in maximizing space, ensuring safety, and enhancing the aesthetics of installations. Galvanized steel, known for its resilience against corrosion and mechanical impacts, makes an excellent choice for manufacturing cable trays. When treated with a hot-dip galvanization process, steel is coated in a layer of zinc, which significantly extends its lifespan, especially in environments exposed to moisture and chemicals.

The Role of Roll Forming Machines

The roll forming machine is a pivotal technology in the cable tray manufacturing process. Roll forming involves the continuous bending of sheet metal in a series of progressive stations, producing a uniform cross-section. The primary advantage of using roll forming machines is their ability to produce high-quality products with minimal waste and reduced labor costs.

Characteristics of Galvanized Steel Cable Tray Roll Forming Machines

1. Precision Engineering Modern roll forming machines are equipped with advanced technology to ensure precision in molding the galvanized steel into various tray designs. This precision reduces the chances of creating defective products, ultimately leading to minimized production costs.

2. Versatility These machines can produce different sizes and shapes of cable trays, adapting to the specific requirements of different projects. Whether it’s a standard cable ladder or a more complex design, the versatility of roll forming machines meets diverse industrial needs.

3. Efficiency The continuous operation capability of roll forming machines leads to high production rates. This efficiency is critical in large-scale operations where time translates directly into money.

4. Eco-Friendly Production The roll forming process generates less waste compared to other fabrication techniques. In addition, the use of galvanized steel contributes to an eco-friendly production approach, aligning with contemporary sustainability goals.

5. Reduced Labor Costs With automated features and minimal manual intervention required, these machines help in significantly cutting down labor costs while maintaining high productivity levels.

Market Demand and Applications

The increasing demand for robust electrical infrastructure across various sectors, including construction, telecommunications, and manufacturing, drives the market for galvanized steel cable trays. Industries are adopting these trays for their reliability and performance, especially where safety and longevity are critical concerns.

Moreover, as electrical systems grow increasingly complex with advances in technology, the need for organized and efficient cable management becomes even more pronounced. The use of galvanized steel cable trays not only ensures compliance with local regulations regarding fire safety and building codes but also enhances overall system reliability.

Future Trends

The future of galvanized steel cable tray roll forming machines is promising. As technology advances, automation will play a more significant role in their operation, driven by Industry 4.0 principles. The integration of artificial intelligence (AI) and machine learning could optimize the production process further, allowing for predictive maintenance and enhanced operational efficiency.

Additionally, the growing emphasis on sustainability may lead to innovations in eco-friendly coatings and materials for cable trays, pushing manufacturers to adapt and innovate continuously.

Conclusion

Galvanized steel cable tray roll forming machines represent a significant advancement in the field of cable management and manufacturing. They not only enhance quality and efficiency but also support sustainable practices in the industry. As technology continues to evolve, these machines will undoubtedly play an integral role in shaping the future of electrical infrastructure, ensuring safe and reliable operations across multiple sectors. Embracing these innovations will be essential for companies aiming to stay competitive in a rapidly changing marketplace.