The Corrugated Sheet Roof Roll Forming Line A Game Changer in Roofing Solutions

In the modern construction industry, the demand for durable and efficient roofing solutions has led to the rising popularity of corrugated sheet roofs. These roofs are not only cost-effective but also exhibit high levels of strength and resilience, making them ideal for various applications. At the heart of this innovative approach to roofing is the corrugated sheet roof roll forming line, a sophisticated piece of machinery designed to mass-produce corrugated sheets with precision and efficiency.

Understanding the Roll Forming Process

The roll forming process involves feeding a continuous strip of metal, typically steel or aluminum, through a series of rollers that progressively shape the material into a desired profile. For corrugated sheets, the roll forming line features multiple sets of rollers that create alternating ridges and troughs, giving the sheets their characteristic corrugated appearance. This unique design not only enhances the aesthetic appeal of buildings but also provides superior structural support.

Advantages of Corrugated Sheet Roofing

1. Durability and Longevity Corrugated sheets are resistant to weather elements such as rain, snow, and wind. They are also less prone to corrosion, especially when coated with protective finishes, making them a long-lasting roofing option.

2. Lightweight Yet Strong One of the significant advantages of corrugated sheet roofs is their weight. While they are lightweight, they offer excellent strength-to-weight ratios, reducing the stress on a building’s structure.

3. Cost-Effectiveness The roll forming process allows for high-volume production, reducing labor and material costs. This affordability makes corrugated roofing a popular choice among builders and homeowners alike.

4. Energy Efficiency Some corrugated sheets are designed to reflect sunlight, contributing to lower energy bills by minimizing heat absorption. This is particularly beneficial in warmer climates where air conditioning costs can skyrocket.

5. Eco-Friendly Many corrugated sheets are made from recyclable materials. The production process can also be optimized for less waste, making it a greener choice in building materials.

The Components of a Roll Forming Line

A typical corrugated sheet roof roll forming line consists of several key components

1. Uncoiler This device unwinds the metal coil, feeding it into the forming system. It's equipped with various controls to manage the tension of the material.

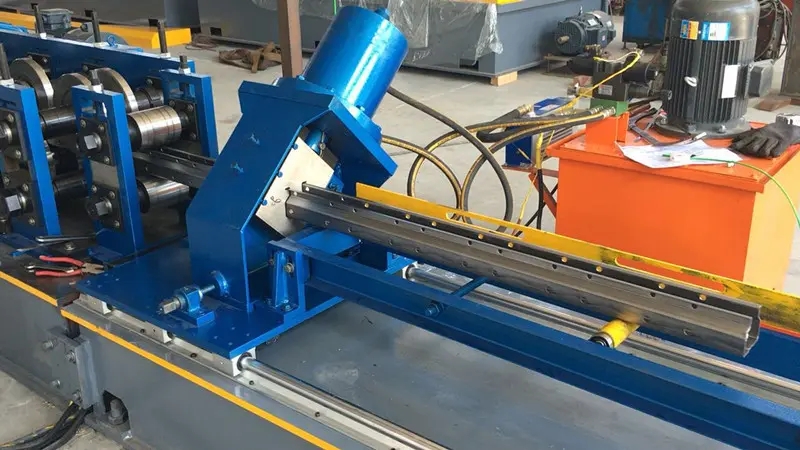

2. Roll Forming Machine This is the main component that shapes the metal. Comprised of multiple rollers, it gradually bends the material into the desired corrugated profile through a series of stages.

3. Cutting System Once the sheet reaches the designated length, a cutting machine or shear is employed to cut the sheets to size. This process occurs in real-time, ensuring that production remains seamless and efficient.

4. Stacking System Finished sheets are automatically stacked for easy handling, packaging, and transportation. Some systems include additional features that can bundle sheets for more efficient shipping.

5. Control Panel Modern roll forming lines are equipped with computerized control systems that allow for precise adjustments and monitoring of the production process. This enhances quality control and reduces material waste.

Conclusion

The corrugated sheet roof roll forming line is revolutionizing how we approach roofing solutions. With the ability to produce high-quality, durable roofing materials efficiently, this machinery plays a pivotal role in meeting the growing demands of the construction industry. Whether for residential homes, commercial buildings, or industrial facilities, corrugated roofs offer a blend of aesthetics, functionality, and sustainability. As technology continues to advance, one can expect to see even greater innovations in roll forming processes, ensuring that corrugated roofing remains a top choice for builders and homeowners alike.