The Advantages and Applications of Upright Rack Roll Forming Machines

In the world of modern manufacturing, efficiency and precision are paramount. One of the key technologies that have emerged to meet these demands is the upright rack roll forming machine. This innovative piece of equipment is specifically designed for the production of upright racks, which are essential components in various industries, including warehousing, retail, and logistics.

Understanding Roll Forming

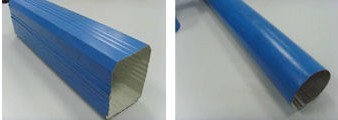

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is passed through consecutive pairs of rollers to create a desired cross-sectional profile. This process is highly efficient and allows for the mass production of complex shapes with minimal waste. The upright rack roll forming machine is specialized for creating racks that are used to store and organize products efficiently.

Key Features of Upright Rack Roll Forming Machines

Upright rack roll forming machines typically come equipped with advanced features that enhance their performance. These machines are capable of forming high-strength materials, including cold-rolled and galvanized steel, which are essential for producing durable racks. Most modern machines also include programmable logic controllers (PLCs) that allow for precise control over the forming process. As a result, manufacturers can achieve consistent dimensions and tolerances, which are crucial for the structural integrity of storage systems.

The ability to produce varying heights, widths, and thicknesses of racks makes these machines highly versatile. Operators can easily adjust the machine settings to accommodate different specifications, allowing for customization based on customer requirements. This adaptability not only enhances productivity but also responds to the ever-changing demands of the market.

Benefits of Using Upright Rack Roll Forming Machines

1. Cost Efficiency By minimizing material waste and maximizing production speed, upright rack roll forming machines help reduce overall manufacturing costs. These machines are designed for long runs, enabling companies to achieve economies of scale.

2. High Strength and Durability The roll forming process strengthens the metal during production, resulting in racks that can withstand heavy loads. This is particularly important in industrial and commercial settings where reliability is crucial.

3. Automation and Precision With the integration of automation technologies, these machines enhance productivity by reducing manual labor and minimizing errors. This precision is vital for ensuring that the racks meet safety standards and perform optimally in their intended applications.

4. Quick Changeover Many upright rack roll forming machines are designed for quick setup and changeover, allowing manufacturers to switch between different product lines with ease. This flexibility contributes to a more dynamic manufacturing environment that can quickly respond to customer needs.

Applications of Upright Racks

Upright racks produced by roll forming machines are used in a variety of sectors. In warehousing operations, they are crucial for maximizing space and ensuring easy access to stored items. Retail environments benefit from upright racks that display products effectively while maintaining an organized layout. Additionally, logistics companies rely on robust racking systems to support the efficient movement and storage of goods.

Perhaps one of the most significant applications is in the manufacturing industry itself, where upright racks are integral in maintaining streamlined production processes. They facilitate the orderly storage of raw materials and finished products, which is vital for maintaining productivity and efficiency on the factory floor.

Conclusion

In summary, upright rack roll forming machines represent a significant advancement in manufacturing technology. Their ability to create high-quality, customizable racks efficiently makes them an invaluable asset for a variety of industries. As companies continue to seek ways to optimize their operations and reduce costs, the role of these machines will likely grow, further cementing their place in the future of production. Embracing the reliability and efficiency of upright rack roll forming machines not only enhances operational capabilities but also sets the stage for long-term success in the competitive manufacturing landscape.