Stud forming machines have revolutionized the construction industry by streamlining the process of fabricating steel studs, which are essential components in modern building frameworks. These machines, known for their precision and efficiency, embody a blend of cutting-edge engineering and user-focused design, making them indispensable in large-scale construction projects.

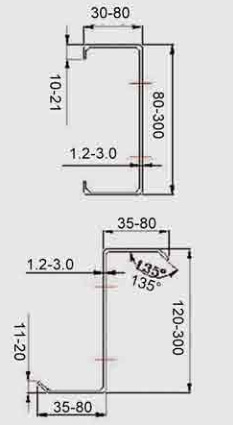

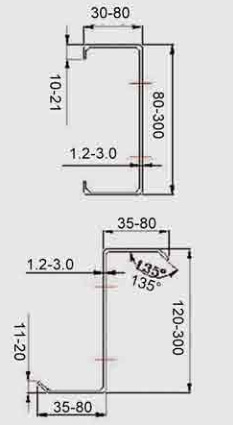

A key feature of stud forming machines is their adaptability. They can handle a range of materials and produce studs of various sizes and shapes, tailored to specific project needs. This flexibility is crucial for meeting the diverse requirements of different construction standards and architectural designs. By customizing the dimensions and materials, construction companies can optimize strength, durability, and aesthetic appeal in their projects.

The modern stud forming machine integrates advanced technologies such as computer numerical control (CNC). CNC enhances the machine’s precision, reducing the likelihood of human error and material wastage. This precision is particularly important when working with designs that require exact specifications, ensuring that each stud perfectly fits within the broader structural framework. The enhanced accuracy also accelerates the construction process, allowing for faster project completion and cost savings.

Efficiency in production is another hallmark of a high-quality stud forming machine. These machines are engineered to operate continuously for long durations without compromising performance. The automation capabilities minimize manual labor, reducing overall labor costs. Moreover, the streamlined operation means that resources, such as electrical power and raw materials, are utilized efficiently, leading to sustainable and eco-friendly construction practices.

User-friendliness is another distinguishing characteristic of stud forming machines. Despite their complexity, these machines are designed to be operated by individuals with minimal technical expertise. Intuitive interfaces and clear operational instructions make it easier for operators to control the machine, conduct routine checks, and perform maintenance. This ease of use translates to higher productivity levels and reduces downtime, enhancing project timelines.

stud forming machine

The durability and reliability of stud forming machines help establish them as trustworthy assets in the construction industry. Manufactured from robust materials and engineered to withstand the rigors of continuous use, these machines offer longevity that translates to a better return on investment. Additionally, reputable manufacturers often provide extensive warranties and customer support services, which further bolsters confidence in their products.

From an expertise standpoint, understanding the intricacies of different stud forming machines requires a thorough knowledge of the latest engineering principles and industry standards. Companies often employ specialists to assess the specific requirements of their projects and recommend suitable machines. This expertise ensures that the selected stud forming machine aligns perfectly with the intended application, optimizing both the construction process and the resultant structural integrity.

Authoritativeness in the choice of stud forming machines is often reflected in the endorsements by industry leaders and the compliance with international quality standards. Machines that bear certifications from recognized industry bodies provide assurance of their capabilities and adherence to rigorous performance criteria. Firms that have garnered recognition for their innovative solutions in engineering offer products that set benchmarks in terms of performance, safety, and environmental consideration.

Trustworthiness, both in the machines and the manufacturers, is paramount. Companies dealing with stud forming machines carry out extensive research and due diligence to ensure that the machines are produced by reputable manufacturers. Transparent communication regarding the machine specifications, capabilities, and limitations is essential. Furthermore, seeking testimonials and reviews from previous users can provide insights into the machine’s real-world performance and reliability.

Incorporating stud forming machines into construction operations not only enhances efficiency and precision but also significantly contributes to the quality and safety of the finished structures. Their role in facilitating faster, cost-effective, and environmentally sustainable building practices cannot be overstated. The continued advancements in technology promise an even brighter future for these vital machines, ensuring they remain at the forefront of structural innovation and construction excellence.