Understanding Drawer Slide Making Machinery

The rise of modern furniture design and manufacturing has led to an increased demand for high-quality drawer slides. These essential components ensure the smooth functioning of drawers in various types of furniture, from kitchen cabinets to office desks. Consequently, the machinery used to produce these slides has become increasingly sophisticated, incorporating advanced technologies to meet the evolving needs of the market.

Overview of Drawer Slides

Drawer slides, also known as drawer runners, are mechanical devices that allow a drawer to open and close smoothly. They play a crucial role in the usability and functionality of furniture, influencing factors such as load-bearing capacity, durability, and ease of use. With a variety of types available—such as side-mounted, under-mount, and center-mounted slides—each design presents unique advantages and is suited for different applications.

The Role of Machinery in Production

The production of drawer slides involves several stages, from material selection to the final assembly. Drawer slide making machinery is specifically designed to automate and streamline this process. Utilizing cutting-edge technology, these machines can significantly enhance productivity while maintaining high standards of quality.

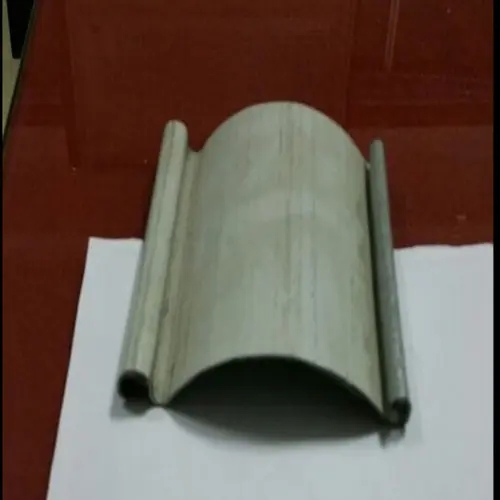

1. Material Processing The first step in drawer slide production typically involves processing raw materials, such as steel, aluminum, or plastic. Machinery like laser cutters and CNC (Computer Numerical Control) machines are employed to accurately cut and shape the raw material into the necessary components. The precision of CNC machines ensures that each part meets the required specifications, which is crucial for the smooth functioning of the final product.

2. Forming and Bending After the initial cutting, forming and bending operations are carried out using specialized machinery. This process allows manufacturers to create the intricate shapes required for the slides. Hydraulic presses and stamping machines are commonly used to ensure a consistent and accurate bend, which is key to the strength and durability of the drawer slides.

3. Surface Treatment To enhance the appearance and resistance of drawer slides against wear and corrosion, surface treatments are applied. Techniques such as powder coating, anodizing, and plating are executed using automated spray booths and dip tanks, ensuring a uniform finish across all pieces.

4. Assembly The assembly of drawer slide components can also be automated. Assembly lines equipped with robotic arms can efficiently position and join various parts, minimizing human error and accelerating production rates. This automation not only improves output but also enhances worker safety by reducing manual handling of heavy or sharp parts.

5. Quality Control Quality assurance is a vital aspect of the production process. Machinery equipped with inspection technologies, such as laser measurement systems and vision systems, can identify defects in the slides at an early stage. This proactive approach to quality control ensures that only products meeting stringent standards are delivered to customers.

The Future of Drawer Slide Manufacturing

As technology continues to advance, the future of drawer slide making machinery looks promising. Innovations such as IoT (Internet of Things) integration, where machines communicate data about production efficiency and maintenance needs, are set to enhance operational performance. Additionally, the increasing focus on sustainable manufacturing practices has led to the development of eco-friendly materials and energy-efficient machines, aligning with global trends toward sustainability.

In conclusion, drawer slide making machinery plays a pivotal role in the furniture industry, driving innovation in design and manufacturing. By incorporating advanced technologies, manufacturers can produce high-quality, reliable drawer slides that cater to the diverse needs of consumers. As the industry evolves, so too will the machinery used, ensuring that production processes remain efficient and sustainable for years to come.