The Steel Wire Straightening and Cutting Machine Enhancing Efficiency in Manufacturing

In the fast-paced world of manufacturing and construction, efficiency and precision are paramount. Among the essential tools that ensure these qualities is the steel wire straightening and cutting machine. This sophisticated piece of equipment is designed to streamline the process of preparing wire for various applications, making it an invaluable asset in industries ranging from automotive to construction.

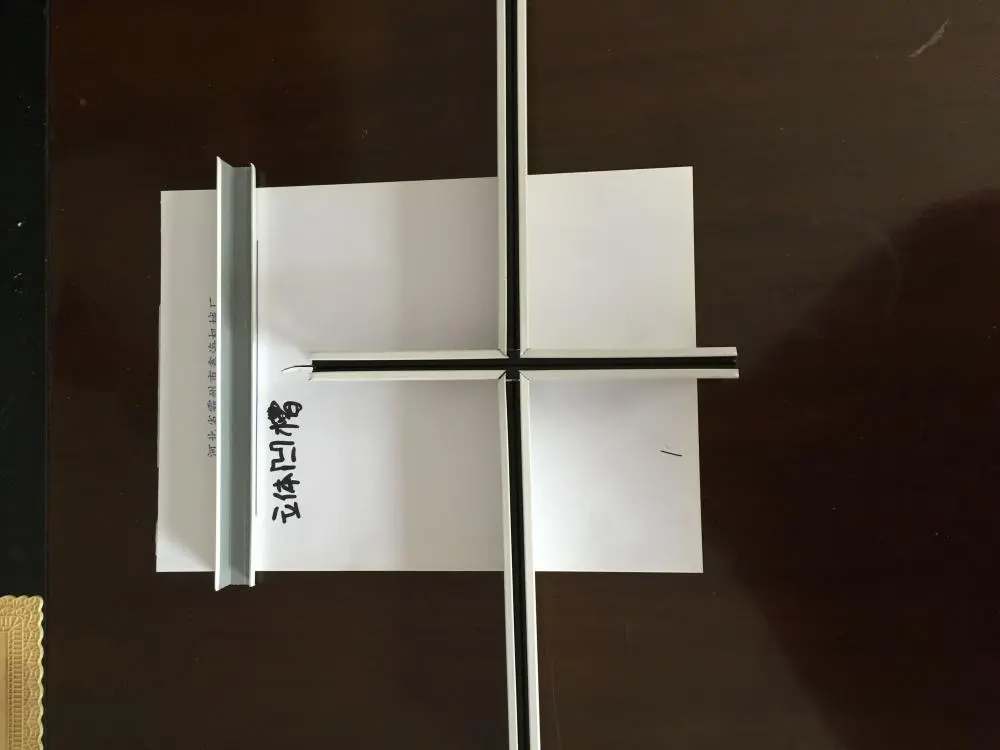

Understanding the Machine

A steel wire straightening and cutting machine typically operates by taking wire that has been produced in coils and processing it into straightened lengths of uniform dimensions. The machine’s operation involves several stages, including feeding, straightening, and cutting. As the wire feeds through the machine, first, the coils are unwound, and then the wire is subjected to a straightening process that eradicates any bends or kinks. Following this, the machine accurately cuts the wire to specified lengths, ready for use in manufacturing components, fasteners, and other applications.

Benefits of Using a Steel Wire Straightening and Cutting Machine

1. Precision and Consistency One of the primary advantages of using these machines is their ability to produce wire lengths that are consistent and precise. Manual cutting and straightening are prone to human error, which can lead to inconsistencies in length and straightness. However, automated machines deliver uniform results every time, which is crucial for mass production.

2. Increased Productivity The integration of a steel wire straightening and cutting machine can significantly boost productivity. These machines can process large volumes of wire in a relatively short time, reducing the overall time spent on wire preparation. This allows manufacturers to focus on other aspects of production, ultimately improving throughput and profitability.

3. Labor Cost Reduction By automating the straightening and cutting processes, companies can reduce their labor costs. Fewer workers are needed to handle wire preparation, as the machine can operate with minimal supervision. This not only saves money but also enables businesses to allocate their workforce to more skilled tasks that require human intervention.

4. Versatility Modern wire straightening and cutting machines are designed to handle a variety of wire diameters and types. This versatility makes them suitable for multiple applications across different industries. Whether manufacturing components for construction, automotive parts, or even electronics, these machines can adapt to meet varying production demands.

5. Quality Assurance The precision provided by these machines translates into higher quality end products. In industries where the integrity of wire is critical—such as aerospace and automotive—ensuring that every piece meets stringent standards is essential. Machines equipped with advanced technology can perform checks and balances, ensuring that the wire being produced meets all necessary specifications.

Technological Advancements

The development of steel wire straightening and cutting machines has witnessed significant advancements in technology. Many of these machines now come with digital controls and monitoring systems that provide real-time feedback and data analytics. This allows operators to track productivity, identify issues quickly, and perform maintenance proactively, minimizing downtime.

Moreover, some modern machines incorporate smart technologies such as IoT (Internet of Things) capabilities. This integration facilitates remote monitoring and control, allowing manufacturers to oversee operations from anywhere, streamline maintenance schedules, and optimize performance further.

Conclusion

In conclusion, the steel wire straightening and cutting machine is a cornerstone of efficiency in many manufacturing processes. Its ability to deliver precision, enhance productivity, reduce labor costs, and ensure product quality makes it an indispensable tool in numerous industries. As technological advancements continue to shape the landscape of manufacturing, these machines will likely evolve further, offering even greater capabilities and efficiencies. Embracing such innovations is essential for businesses seeking to maintain a competitive edge in an ever-evolving market. Whether it’s for automotive applications, building infrastructure, or various manufacturing needs, the steel wire straightening and cutting machine will remain a pivotal element in achieving production excellence.