The Square Steel Pipe Making Machine Transforming Raw Steel into Structural Solutions

In the ever-evolving world of construction and manufacturing, square steel pipes have emerged as a crucial element for modern infrastructure. They offer superior strength, versatility, and an extensive range of applications. At the heart of the production of these robust structural components lies the square steel pipe making machine, a sophisticated piece of equipment that has revolutionized the way steel pipes are produced.

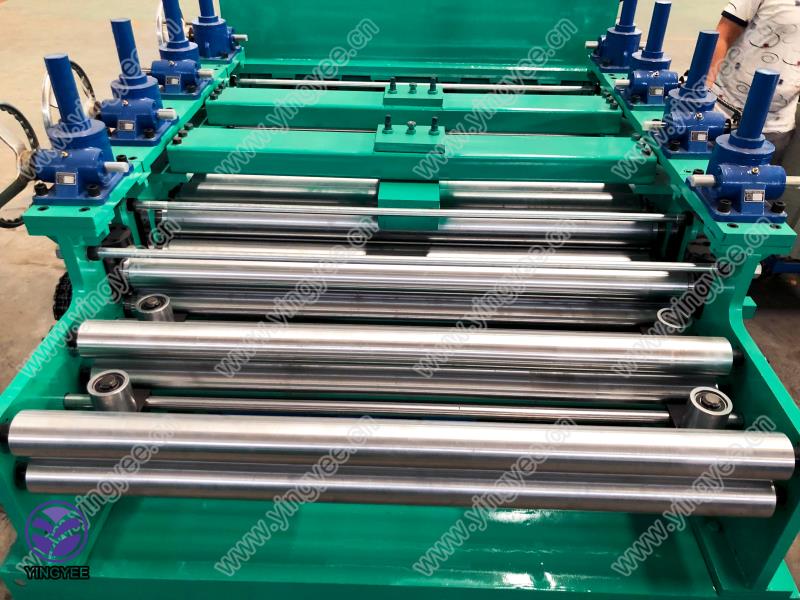

The square steel pipe making machine operates through a process known as high-frequency welding. This method begins with the feeding of flat steel strips into the machine, where they undergo a series of forming operations. These operations include bending the strips into a square shape and welding the edges together to create a continuous tube. The high-frequency welding process involves using induction heating to ensure a strong and durable weld, critical for the integrity of the final product.

One of the primary advantages of using a square steel pipe making machine is the efficiency with which it can produce pipes in various sizes and thicknesses. Manufacturers can customize their output to meet specific requirements, enabling the production of square steel pipes that are ideal for construction, automotive, and manufacturing industries. Furthermore, the machinery is capable of operating at high speeds, significantly increasing production rates and reducing the time needed to bring products to market.

Quality control is another crucial aspect of the square steel pipe manufacturing process. Advanced machines come equipped with various inspection tools that monitor the welding process in real-time, ensuring that the pipes meet the stringent industry standards for quality and safety. These machines can detect imperfections such as misalignment or insufficient weld penetration, allowing for immediate adjustments to be made, thereby minimizing waste and ensuring a high-quality end product.

Additionally, the introduction of automation and control technology in square steel pipe making machines has further enhanced efficiency and precision. Operators can use sophisticated software to control various parameters such as temperature, welding speed, and pressure, allowing for greater control over the manufacturing process. This level of automation not only improves product quality but also reduces labor costs and minimizes human error, creating a more streamlined production line.

Sustainability is also becoming increasingly important in modern manufacturing practices. Square steel pipe making machines are now designed with energy-efficient features that reduce energy consumption during production. Furthermore, steel is a fully recyclable material, and many manufacturers are committed to using recycled steel in their production processes. This commitment not only conserves natural resources but also aligns with global efforts to promote environmentally friendly practices in manufacturing.

The versatility of square steel pipes makes them ideal for a myriad of applications. From structural supports in buildings to frames for vehicles, road barriers, and furniture, the demand for square steel pipes continues to rise. As the construction and manufacturing industries grow, the need for efficient and reliable production methods such as those provided by square steel pipe making machines will only increase.

In conclusion, the square steel pipe making machine plays a pivotal role in meeting the growing demand for high-quality steel pipes in various industries. Its ability to produce pipes efficiently, coupled with advancements in technology and a commitment to sustainability, makes it an invaluable asset in the modern manufacturing landscape. As we move towards a future that increasingly prioritizes both quality and environmental responsibility, the significance of this machinery will become even more pronounced, ensuring that the buildings, vehicles, and infrastructure of tomorrow are built on a foundation of strength and resilience.