The PPGI Glazed Tile Roofing Making Machine Revolutionizing Construction

In modern construction, durability and aesthetic appeal are paramount. One of the innovative solutions that have emerged in recent years is the usage of PPGI (Pre-Painted Galvanized Iron) glazed tile roofing making machines. These machines enable the production of high-quality roofing materials that not only enhance the beauty of structures but also offer superior protection against the elements.

Understanding PPGI Glazed Tiles

PPGI is a type of steel that has been coated with a layer of zinc and then painted with a protective layer of paint. This process enhances the material's resistance to corrosion, UV radiation, and wear. The glazed tile effect provides a classic appearance reminiscent of traditional clay tiles, but with the added benefits of PPGI. The result is a roofing solution that combines the aesthetic charm of ceramic tiles with the strength and durability of metal.

The Role of Roofing Making Machines

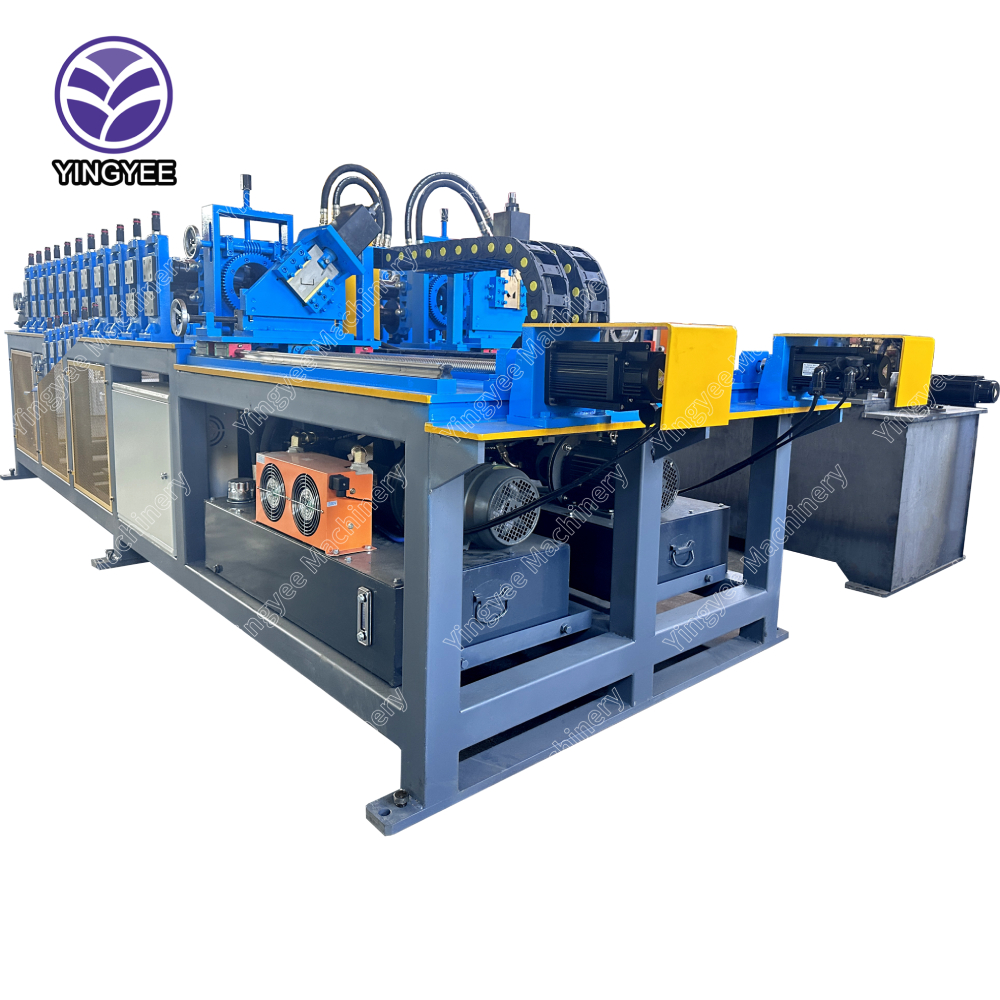

The PPGI glazed tile roofing making machine plays a critical role in the production of these roofing materials

. Utilizing advanced technology, these machines can produce various styles and profiles of PPGI glazed tiles, meeting the diverse needs of the construction industry. The machines allow for high-speed production and precise manufacturing, which reduces waste and improves efficiency.1. High Efficiency Modern PPGI glazed tile roofing machines are designed to operate at high speeds. This capability translates to a greater output in less time, enabling manufacturers to meet large-scale demands easily. The continuous production process reduces downtime, leading to cost-effectiveness.

2. Customization Options One of the standout features of these machines is their ability to produce customized tiles. The settings can be adjusted to create different shapes, sizes, and colors, allowing architects and builders to fulfill specific design requirements without compromising on quality.

3. Durability and Strength The materials produced by these machines are robust and durable, able to withstand harsh weather conditions like heavy rain, strong winds, and intense sunlight. The glazed finish further protects the tiles, ensuring they retain their color and appearance over time.

4. Sustainability As the construction industry moves towards more sustainable practices, the use of PPGI glazed tiles is an attractive option. The metal can be recycled at the end of its life, minimizing environmental impact. Additionally, the energy efficiency of metal roofs can contribute to lower energy consumption for heating and cooling buildings.

Conclusion

The advent of PPGI glazed tile roofing making machines marks a significant advancement in roofing technology. They offer a perfect blend of aesthetics and functionality, making them indispensable for both residential and commercial construction projects. As construction needs evolve, relying on innovative machines to produce high-quality building materials will only become more critical.

In conclusion, as the market for PPGI glazed tiles continues to expand, manufacturers who invest in these advanced machines will likely gain a competitive edge. The benefits encompass high efficiency, customization, durability, and sustainability—key attributes that will shape the future of roofing solutions. Whether one is looking to modernize a home or construct a new facility, embracing PPGI glazed tiles produced by cutting-edge machinery can lead to lasting value and appeal in any architectural endeavor.