The Evolution and Significance of Metal Stud Machines in Modern Construction

In the ever-evolving landscape of construction technology, the emergence of metal stud machines has revolutionized the framing process. These machines are pivotal in the manufacture and assembly of metal studs, which serve as a lightweight and durable alternative to traditional wooden framing systems. As the construction industry increasingly shifts toward efficiency, speed, and sustainability, understanding the importance and capabilities of metal stud machines becomes essential.

1. The Basics of Metal Studs

Metal studs are made from galvanized steel, offering numerous advantages over their wooden counterparts. They are resistant to termites, mold, and rot, which enhances their longevity and reduces maintenance costs. Additionally, metal studs are consistent in size and shape, ensuring a high level of precision in construction projects. This uniformity plays a crucial role in achieving structural integrity and alignment, which is essential for both aesthetic and functional aspects of buildings.

2. The Role of Metal Stud Machines

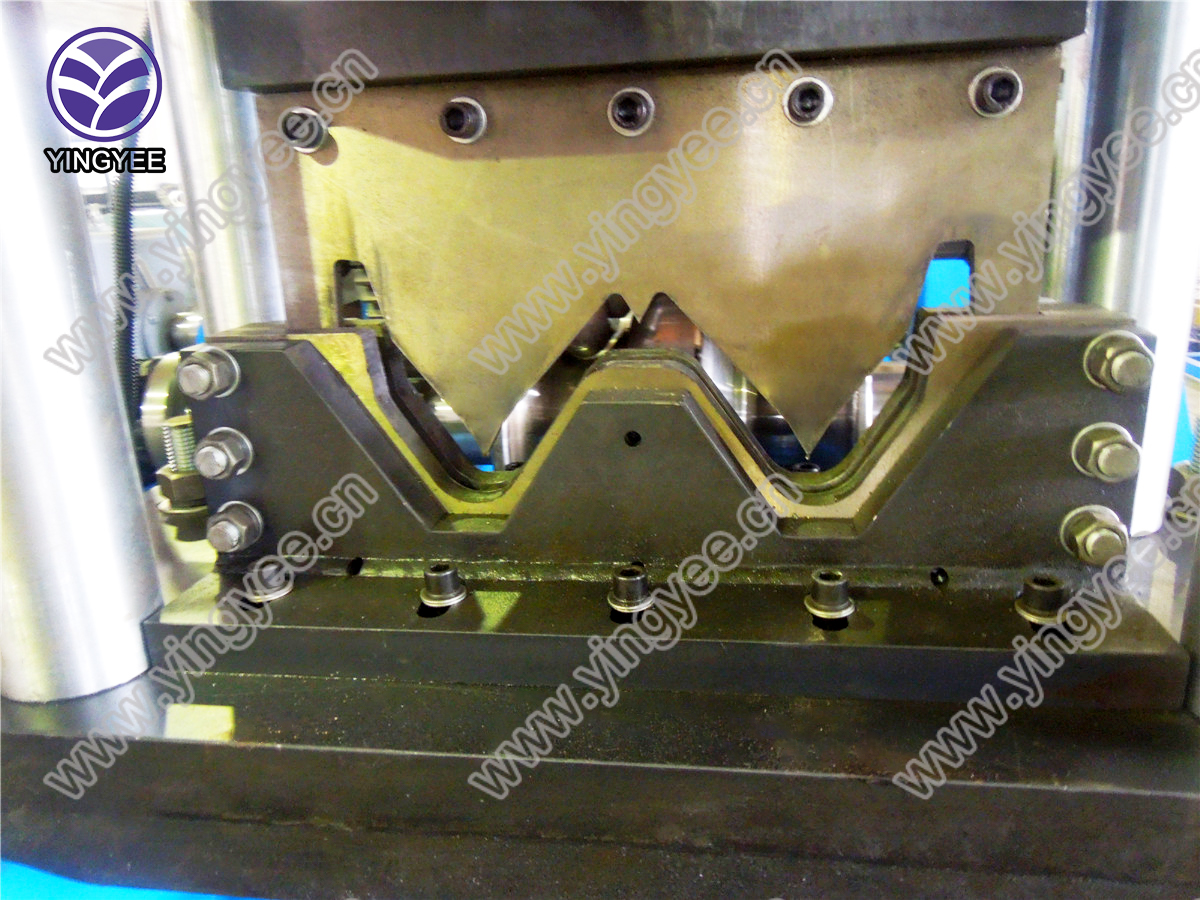

Metal stud machines automate the process of fabricating metal studs, reducing the manual labor required in construction. These machines can efficiently cut, punch, and shape metal sheets into the desired dimensions for studs, tracks, and other framing components. The automation not only speeds up production but also minimizes human error, leading to higher quality outputs.

Modern metal stud machines come equipped with advanced features such as computer numerical control (CNC) systems, which allow for intricate and precise cuts. This technological advancement enables manufacturers to produce custom sizes and shapes, catering to specific project requirements. The introduction of CNC technology has transformed the metal stud manufacturing process, providing flexibility and enhancing productivity.

3. Applications of Metal Stud Machines

Metal stud machines are integral to various construction applications, including commercial buildings, schools, hospitals, and residential properties. They are particularly favored in environments where fire resistance and earthquake resilience are important considerations. The use of metal studs allows for the construction of lighter structures with the ability to bear heavy loads, making them suitable for multi-story buildings.

Furthermore, the compatibility of metal studs with various insulation and cladding materials enhances their versatility in modern architecture. From drywall installations to curtain wall systems, the adaptability of metal stud frameworks supports diverse design visions while ensuring compliance with building codes.

4. Benefits Beyond Construction

The impact of metal stud machines extends beyond the construction site. Their efficiency contributes to sustainable building practices by reducing waste generated during the fabrication process. Metal studs are often made from recycled materials, and their recyclability at the end of their life cycle promotes a circular economy.

Moreover, by enabling faster construction times, metal stud machines help meet the increasing demand for quick and efficient project completions. This is particularly critical in an era where the real estate market is rapidly evolving, and clients seek timely delivery without compromising on quality.

5. Future Trends in Metal Stud Production

As technology progresses, the future of metal stud machines looks promising. Innovations such as artificial intelligence and machine learning are expected to enhance the operational capabilities of these machines further. Predictive maintenance, optimization of production processes, and real-time monitoring are some potential advancements that may redefine how metal studs are manufactured.

Additionally, as the construction industry becomes more focused on sustainability, further developments in the production of eco-friendly metal studs could emerge. Innovations aimed at reducing energy consumption during manufacturing while enhancing the performance of metal frames are likely to drive the market forward.

Conclusion

In conclusion, metal stud machines are transforming the construction landscape by providing an efficient, sustainable, and reliable solution for modern framing needs. As the industry embraces technological advancements, these machines will continue to play a pivotal role in shaping the future of construction. By understanding the capabilities and benefits of metal stud machines, stakeholders in the construction sector can harness their potential to create efficient and resilient structures that meet the demands of contemporary society. The ongoing evolution of these machines promises to deliver even greater innovations, paving the way for a more sustainable and technologically advanced construction environment.