The Evolution and Significance of China Sandwich Panel Lines

In recent years, the construction industry has witnessed a remarkable evolution, driven by the incessant demand for efficient, cost-effective, and sustainable building materials. One such advancement is the development of sandwich panels, which have gained immense popularity in various sectors, including commercial, industrial, and residential construction. Central to this advancement is the sophisticated machinery known as the China sandwich panel line, which plays a pivotal role in the production of these innovative construction materials.

Understanding Sandwich Panels

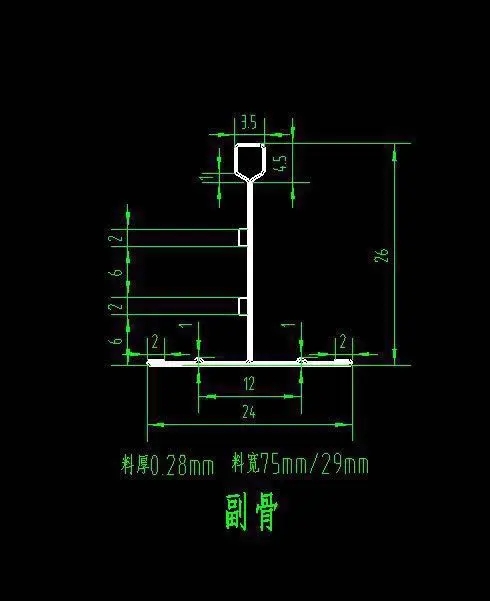

Sandwich panels are composite building materials made up of two outer layers (faces) and a core layer in between. Typically, the outer layers are composed of metal, such as steel or aluminum, while the core may be made of polystyrene, polyurethane, or mineral wool. This structural configuration allows sandwich panels to offer remarkable strength, insulation properties, and lightweight characteristics, making them an ideal choice for modern construction.

These panels are manufactured in various thicknesses and dimensions, catering to different requirements and applications. The versatility of sandwich panels has made them a go-to solution for walls, roofs, and even flooring in many construction projects.

The Role of China Sandwich Panel Lines

The China sandwich panel line is a sophisticated piece of equipment designed for the continuous production of sandwich panels. These lines are equipped with advanced technology that enables the seamless integration of raw materials, including the automatic mixing and foaming of the core material, as well as the precise lamination of outer layers.

The manufacturing process begins with the preparation of the core material, which is then injected or expanded between the two outer layers. These lines typically feature automation and digital control systems that enhance productivity and ensure consistent quality. This manufacturing process not only reduces labor costs but also minimizes human error, thereby increasing the reliability of the final products.

Market Demand and Growth

The demand for sandwich panels has surged in China and globally, driven by the rapid urbanization and industrialization trends. With the growing emphasis on sustainable construction, builders are increasingly opting for materials that not only meet regulatory requirements but also promote energy efficiency. Sandwich panels, with their inherent insulation properties, help reduce energy consumption in buildings, making them an eco-friendly choice.

Furthermore, the efficient production methods employed in the China sandwich panel line have contributed to a significant reduction in production lead times, ensuring that projects remain on schedule. The ability to produce high volumes of panels quickly is a substantial advantage in a competitive market, where delays can lead to increased costs.

Innovation and Technology

With the ongoing advancements in technology, China sandwich panel lines are continuously evolving. Manufacturers are incorporating cutting-edge technologies such as artificial intelligence, IoT (Internet of Things), and advanced robotics into their production processes. These innovations lead to enhanced operational efficiency, predictive maintenance, and improved product quality.

Moreover, these lines are designed to be more adaptable to different product specifications, allowing manufacturers to respond to market trends and consumer preferences swiftly. The integration of automation not only boosts efficiency but also expands the capacity for customization, enabling producers to cater to niche markets that require specific panel designs or materials.

Conclusion

The China sandwich panel line exemplifies the remarkable intersection of technology and construction, epitomizing the shift towards modern building practices. As the demand for sandwich panels continues to rise, driven by factors such as sustainability, efficiency, and design flexibility, the significance of these production lines in the global market cannot be overstated.

Overall, sandwich panels produced by these sophisticated lines are set to play an increasingly important role in the future of construction, reflecting the industry's broader trends towards innovation and sustainability. The continuous investment in and development of sandwich panel technology not only signifies a commitment to advancements in building materials but also heralds a new era of construction possibilities that prioritize efficiency, quality, and environmental responsibility. As we move forward, the potential for sandwich panels in transforming the construction landscape remains vast and exciting.