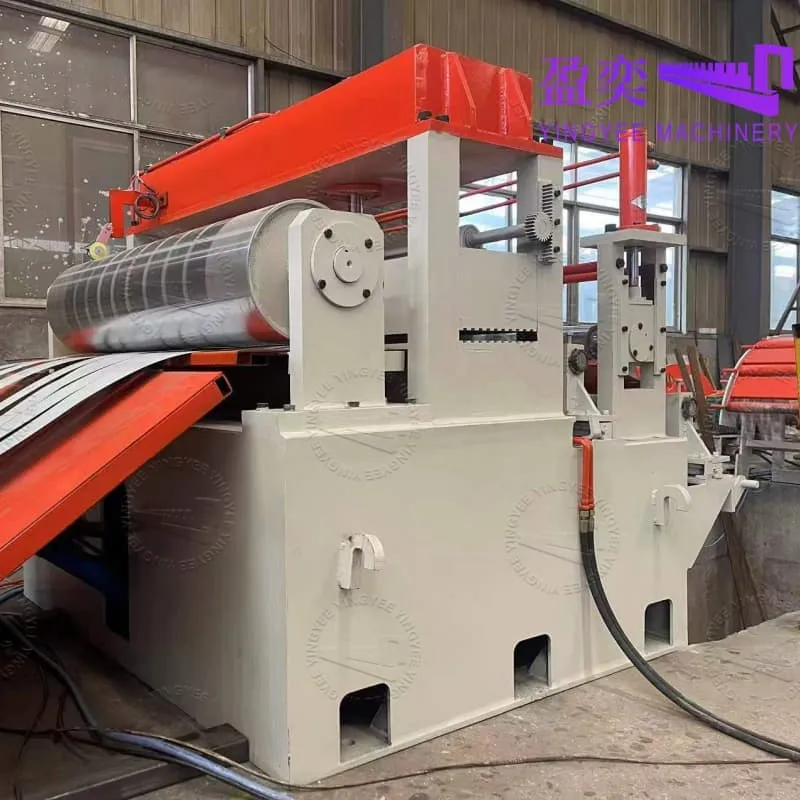

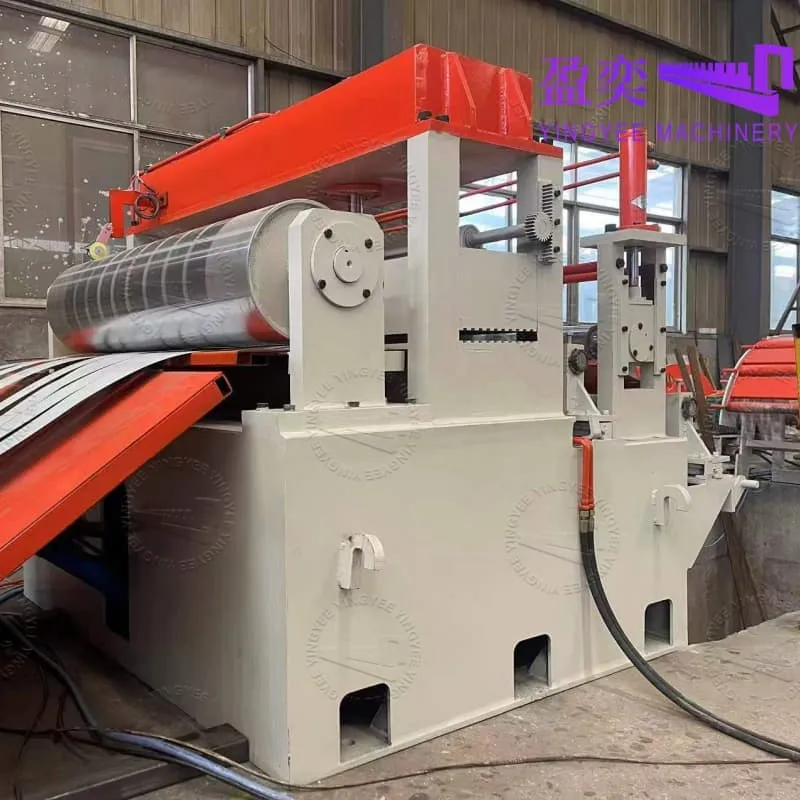

This conventional production line can do galvanized, hot-rolled, stainless steel slitting with a thickness of 0.3mm-3mm and a maximum width of 1500. The minimum width can be divided into 50mm. It can be made thicker and needs special customization.

According to different thickness, this machine speed is between 120-150m/min.

The length of the whole line is about 30m, and two buffer pits are needed.

Independent traction + leveling part, and the deviation correction device ensures the precision of the slitting, and the width of all positions of the finished product is consistent.

Tensioning part + seamless winding machine to ensure tight winding material.

Standard 10ton decoiler, optional 15, 20ton.

The speed is very fast and the production capacity is high. Compared with the low-speed machine, the output and energy consumption at the same time have obvious advantages.

Brand-name electrical appliances such as Mitsubishi, Yaskawa, etc., are of reliable quality and good after-sales.