The Evolution and Importance of Steel Pipe Making Machines

In the modern industrial landscape, steel pipes play a crucial role in various applications ranging from construction and plumbing to oil and gas transportation. The manufacturing process of these pipes has evolved significantly over the years, primarily due to advancements in technology and machinery. One of the key components in the production of steel pipes is the steel pipe making machine. This article delves into the importance, types, and technological advancements of steel pipe making machines.

The Importance of Steel Pipe Making Machines

Steel pipes are fundamental in many sectors due to their strength, durability, and resistance to corrosion. The demand for these pipes is continuously increasing, driven by the rapid growth of industries such as construction, agriculture, and energy. To meet this demand efficiently, steel pipe making machines have become indispensable. These machines enable manufacturers to produce high-quality steel pipes in varying sizes and specifications, ensuring that they meet the diverse needs of different industries.

The efficiency of steel pipe making machines also significantly reduces production costs and time

. In a competitive market, manufacturers must optimize their processes to maximize productivity while minimizing waste. Modern machinery incorporates automation and precision engineering, allowing for streamlined operations and enhanced output.Types of Steel Pipe Making Machines

There are several types of steel pipe making machines, each designed for specific manufacturing processes. The most common types include

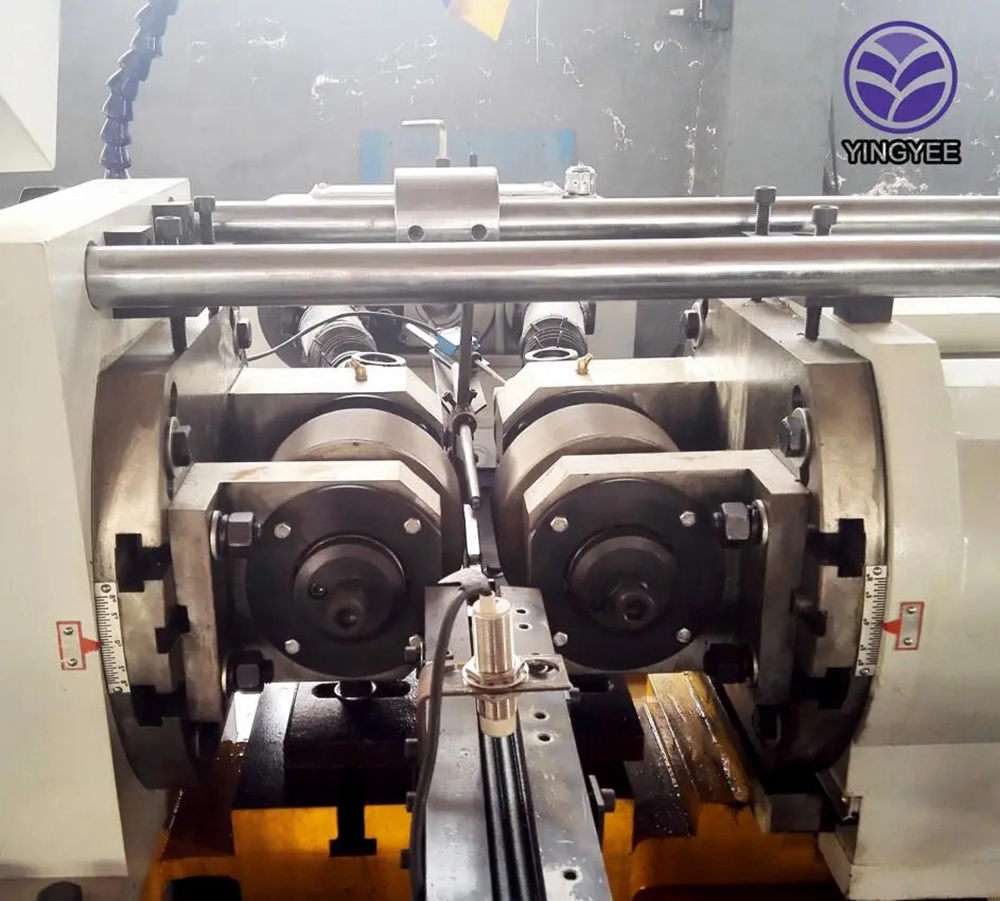

1. High-Frequency Welded Pipe Machines These machines utilize high-frequency induction heating to weld the edges of steel strips together, forming pipes. This method is particularly effective for producing pipes with a smaller diameter and offers faster production rates.

2. ERW (Electric Resistance Welded) Pipe Machines Similar to high-frequency welded machines, ERW machines use electric resistance to weld. However, they are typically used for larger diameter pipes and offer an excellent balance between speed and quality.

3. Seamless Pipe Mills These machines are designed for the production of seamless pipes, which are made from solid round billets. The process involves heating the billet and then piercing it to create a hollow tube. Seamless pipes are known for their strength and are widely used in high-pressure applications, making these machines vital in certain sectors.

4. Spiral Pipe Machines These machines produce pipes in a spiral configuration, which enhances the structural integrity and flexibility of the pipes. They are often used in the construction of large storages and for water and natural gas transportation.

Technological Advancements

The steel pipe manufacturing industry has witnessed significant technological advancements in recent years. Automation and computerized systems have been integrated into manufacturing processes, enhancing precision and reducing human error. These advancements have allowed for real-time monitoring of production parameters, ensuring that products meet the required standards.

Moreover, improvements in materials and coatings have increased the efficiency and longevity of the pipes produced. Modern machines are also capable of producing a wide range of pipe sizes and wall thicknesses, further increasing their versatility.

Energy efficiency is another crucial aspect that has been addressed through technology. Many contemporary steel pipe making machines are designed to consume less energy and produce less waste, aligning with global sustainability goals.

Conclusion

In conclusion, steel pipe making machines are the backbone of the steel pipe manufacturing industry. With their ability to produce high-quality products efficiently, they play a significant role in meeting the increasing demand across various sectors. As technology continues to advance, we can expect even more innovations in the machinery used for steel pipe production, ultimately leading to better products and more sustainable manufacturing practices. These machines not only contribute to the efficiency of production but also significantly impact the quality and availability of steel pipes in a rapidly evolving industrial economy. Thus, the importance of investing in advanced steel pipe making machines cannot be overstated, as they are integral to both the growth of industries and the infrastructure that supports modern life.