Understanding Cable Tray Roll Formers Essential Tools for Efficient Cable Management

In today’s fast-paced technological landscape, the efficient management of cables is crucial for ensuring the reliability and performance of electrical systems. Cable trays play a pivotal role in organizing and supporting electrical wiring, making cable tray roll formers an essential tool in the manufacturing process. This article delves into the importance of cable tray roll formers, their operation, and their impact on the industry.

What is a Cable Tray Roll Former?

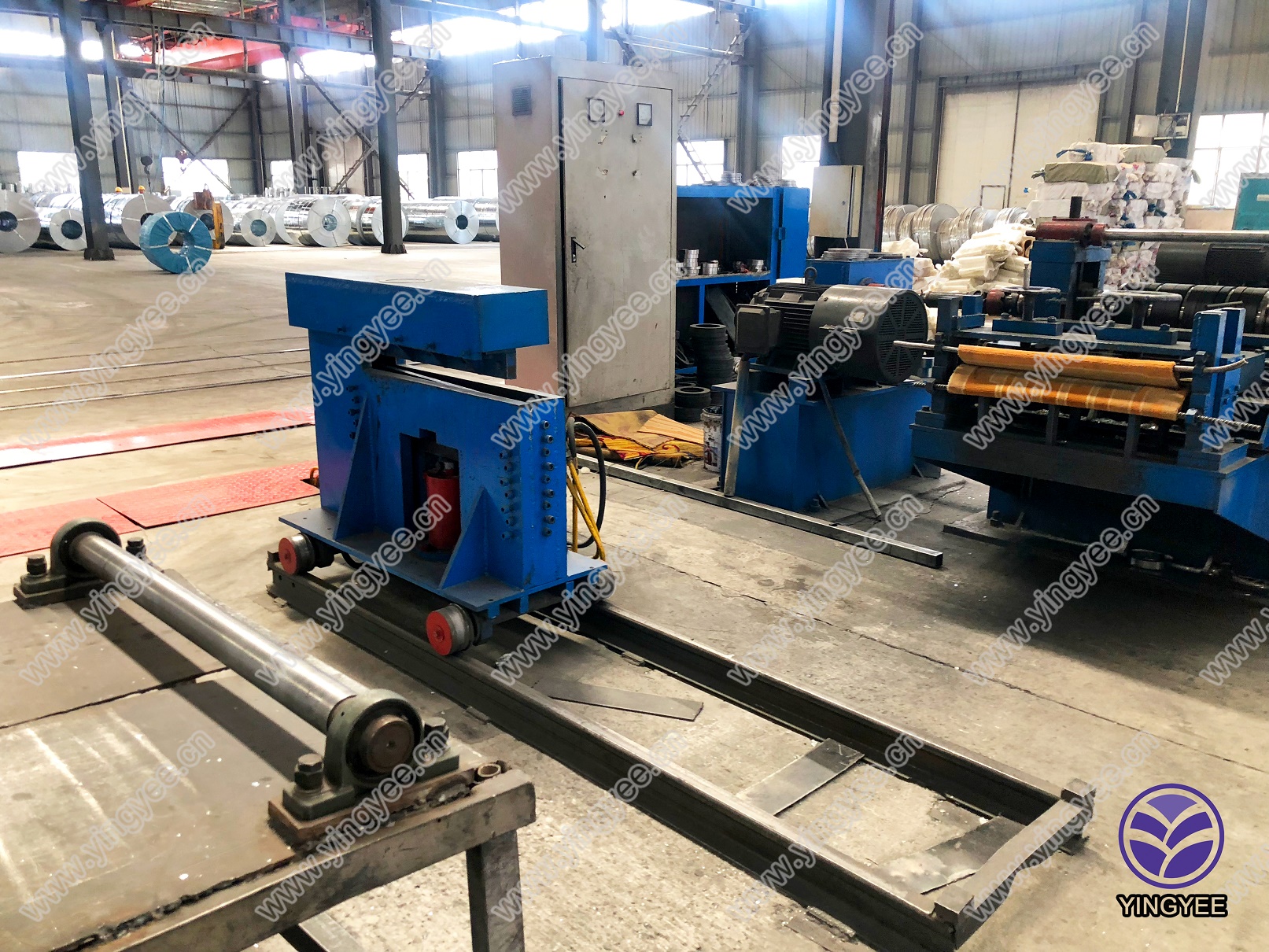

A cable tray roll former is a specialized machine designed to produce cable trays from metal sheets. These machines utilize the roll forming process, where a continuous strip of metal is fed through a series of rollers that progressively shape it into the desired profile. This method allows for high-volume production of cable trays with consistent quality and precision.

Importance of Cable Trays

Cable trays are vital components in various industrial and commercial applications. They provide support for electrical cables, promoting safety by preventing damage and reducing the risk of electrical faults. In addition, cable trays facilitate proper ventilation, allowing for heat dissipation from electrical systems. By using cable trays, businesses can improve organization, accessibility, and maintenance of their wiring infrastructure.

The Roll Forming Process

The roll forming process consists of several steps. Initially, large metal sheets are cut to size, and then they are fed into the roll former. As the metal passes through the machine, it undergoes a series of bends and shapes created by strategically placed rollers. This process not only creates the structural integrity required for cable trays but also allows for the integration of features such as holes for cable attachment and support brackets.

Advantages of Using Cable Tray Roll Formers

1. Efficiency and High Production Rates Cable tray roll formers are designed for continuous operation, enabling manufacturers to produce large quantities of cable trays in a short time. This efficiency is crucial in meeting the demands of rapid construction and installation projects.

2. Cost-Effectiveness By automating the manufacturing process, businesses can reduce labor costs and minimize material waste. The precision of roll forming ensures that every inch of material is utilized effectively, contributing to overall cost savings.

3. Customizability Roll formers can be adjusted to create various sizes and shapes of cable trays, allowing manufacturers to cater to specific customer requirements. This versatility enables companies to innovate and stay ahead in a competitive market.

4. Durability and Quality Cable trays produced through roll forming exhibit superior mechanical properties and durability. The design flexibility allows for the incorporation of tough materials and protective coatings, ensuring that the trays can withstand harsh environmental conditions.

The Role of Cable Tray Roll Formers in the Industry

The increasing demand for efficient cable management solutions is driving the growth of the cable tray industry. With advancements in technology, modern roll formers are equipped with features such as computer numerical control (CNC) systems, enabling precise programming and automation. This not only enhances accuracy but also streamlines production processes, leading to higher quality outputs.

Moreover, the rise of renewable energy projects and the expansion of telecommunication infrastructures have further escalated the need for effective cable management systems. As industries continue to evolve, the role of cable tray roll formers will remain integral in supporting the infrastructure that underpins modern society.

Conclusion

In conclusion, cable tray roll formers are indispensable tools in the manufacturing of cable trays. Their ability to produce high-quality, durable products efficiently positions them at the forefront of cable management solutions. As the demand for electrical infrastructure grows, so will the significance of roll formers, ultimately contributing to a safer, more organized, and efficient management of cables in various applications. Investing in advanced roll forming technology will ensure that manufacturers can meet the evolving needs of the industry while maintaining the highest standards of quality.