The Evolution of Round and Square Steel Pipes Forming Machines

In modern manufacturing, the production of round and square steel pipes plays a crucial role in various industries, from construction to automotive. The introduction of high-tech steel pipes forming machines has significantly transformed the efficiency and precision of pipe manufacturing, making it a vital component in any metalworking facility.

Round and square steel pipes are essential due to their structural integrity and versatility. They are utilized in applications ranging from structural support in buildings to fluid transport in pipelines. To meet the ever-increasing demand for these products, forming machines have seen rapid advancements in technology.

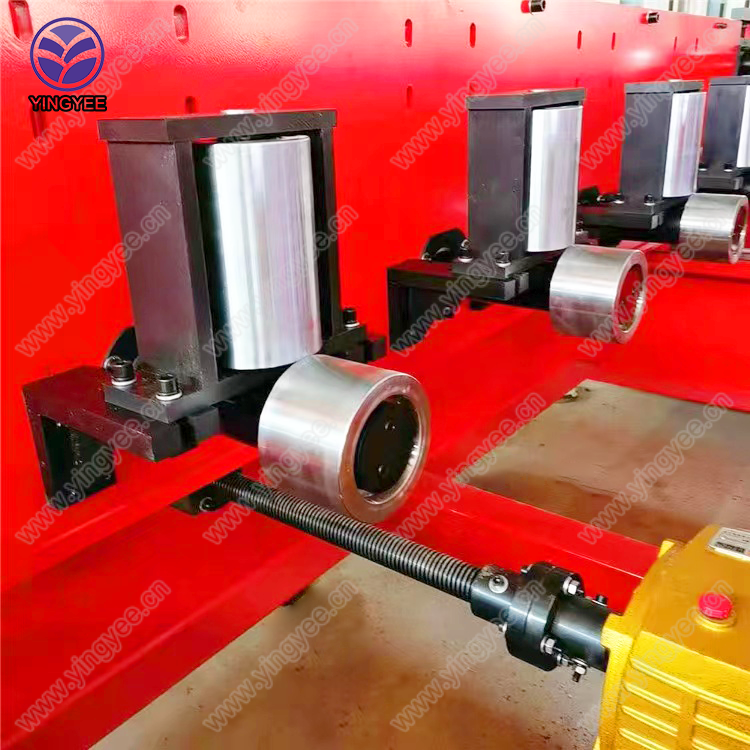

A round and square steel pipes forming machine is designed to shape and weld steel strips into pipes of various dimensions. The process typically involves several key stages feeding, forming, welding, and cutting. Initially, flat steel strips are fed into the machine, where they are gradually bent into the desired shape. This is done using precise rollers that manipulate the strip into a circular or square cross-section.

Once the required shape is achieved, the edges of the steel strip are brought together and welded to form a continuous pipe. Modern machines employ various welding techniques, including High-Frequency Induction (HFI) welding, which provides strong, reliable joints while minimizing heat-affected zones. This advanced method not only enhances the productivity of the manufacturing process but also ensures the quality of the final product.

The cutting stage produces the finished pipes, which can be easily customized in lengths as required by customers. Additionally, many machines are equipped with automatic control systems, allowing for high levels of precision and repeatability in production. This automation reduces human error, increases output rates, and ultimately lowers manufacturing costs.

Moreover, the versatility of forming machines allows manufacturers to produce a variety of pipe sizes and wall thicknesses. This adaptability is crucial in meeting the specific needs of diverse sectors, ensuring that they can provide tailored solutions for their clients.

In conclusion, the development of round and square steel pipes forming machines represents a significant evolution in the manufacturing industry. With their ability to combine efficiency, precision, and versatility, these machines play a fundamental role in the production of essential materials that cater to numerous applications, driving both innovation and economic growth in the steel pipe manufacturing sector.