The Evolution and Importance of Roofing Sheet Forming Galvanized Steel Machines

The roofing industry has seen significant advancements in technology over the years, with galvanized steel becoming a preferred material for roofing solutions. The roofing sheet forming galvanized steel machine is a cornerstone of this evolution, revolutionizing how roofing sheets are produced and distributed. This article explores the significance, functionality, and benefits of these machines in the construction and roofing industries.

Understanding Galvanized Steel

Galvanized steel is steel that has been coated with a layer of zinc to prevent corrosion and rusting. This protective coating extends the lifespan and durability of steel, making it an ideal choice for roofing applications. The longevity of galvanized steel roofs can reach up to 50 years or more with minimal maintenance, significantly reducing the need for replacement and saving costs in the long run.

The Role of Roofing Sheet Forming Machines

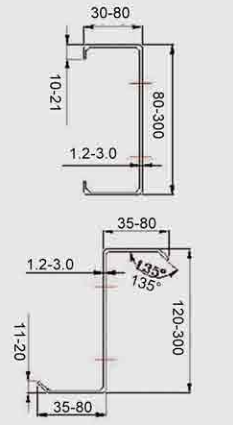

Roofing sheet forming machines are specialized equipment designed to transform steel coils into various roofing sheet profiles. The process typically involves feeding large rolls of galvanized steel into the machine, where they are shaped and cut into desired sizes. These machines can produce different types of roofing sheets such as corrugated, trapezoidal, and tile-shaped profiles, catering to a variety of architectural needs and aesthetic preferences.

How the Machines Work

The roofing sheet forming process begins with the uncoiling of galvanized steel sheets, which are typically fed into the machine through a series of rollers. The steel passes through a series of forming stations, where it is gradually shaped into the desired profile. Each station in the machine is equipped with rollers and molds that define the shape of the roofing sheet.

Once the sheets have been formed, they are cut to the specified lengths using a cutting mechanism, often a hydraulic shear or a pneumatic cutter. The entire process can be automated, allowing for rapid production and minimal labor costs. Advanced machines can also be equipped with computers for precise control and programming of the sheet dimensions, enhancing efficiency and accuracy.

Benefits of Roofing Sheet Forming Machines

1. Efficiency Modern roofing sheet forming machines are capable of producing a high volume of sheets quickly. This efficiency meets the growing demand for roofing materials in the construction industry, especially in urban areas experiencing rapid growth.

2. Cost-Effectiveness By automating the production process, these machines reduce labor costs and minimize material waste. The long-term durability of galvanized steel roofing also translates to lower maintenance costs, making it an economically sound choice for builders and homeowners alike.

3. Versatility These machines can produce a wide range of roofing profiles, allowing manufacturers to meet diverse customer needs. The adaptability of roofing sheet forming machines enables customization of designs, colors, and finishes, catering to various architectural styles.

4. Quality Control Automated processes enhance quality control, ensuring that each roofing sheet meets specified standards. Consistent thickness and shape lead to improved performance and reliability in the field.

5. Sustainability Utilizing galvanized steel as the primary material promotes sustainability, as it is recyclable and often made from recycled materials. Moreover, its longevity reduces the frequency of roof replacements, contributing to waste reduction.

Conclusion

The advancement of roofing sheet forming galvanized steel machines has significantly transformed the roofing industry. Their ability to produce high-quality, cost-effective, and versatile roofing materials has made them invaluable to manufacturers and builders. As the demand for sustainable and durable roofing solutions continues to grow, these machines will play an increasingly important role in shaping the future of construction and architectural design. Embracing this technology not only enhances efficiency but also promotes sustainability, ensuring that we meet the roofing needs of today while preserving resources for future generations.