Understanding Downspout Pipe Forming Machines

In the ever-evolving manufacturing landscape, downspout pipe forming machines have carved a niche due to their essential role in producing effective and durable downspout systems for buildings. Rainwater management is a critical aspect of architectural design, and downspouts are integral to this process, channeling rainwater from roofs away from foundations to prevent water damage. The efficiency and precision of downspout pipe forming machines are vital to ensuring that these systems perform optimally.

The Importance of Downspouts in Modern Construction

Downspouts, typically incorporated into gutter systems, are vertical pipes that direct rainwater from the roof down to the ground. Their primary purpose is to prevent water from accumulating around the foundation of a building, which can lead to significant structural issues. These pipes also help in managing water flow to drainage systems, ensuring that properties remain safe from flooding and water-related damage. Given their importance, the manufacturing process of downspout components must prioritize both quality and efficiency.

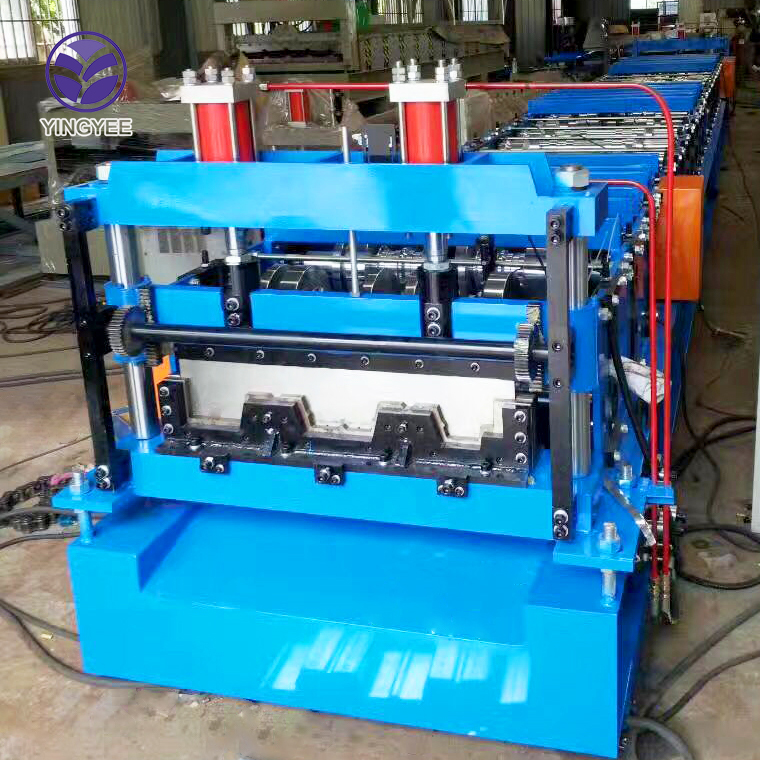

What is a Downspout Pipe Forming Machine?

A downspout pipe forming machine is a specialized piece of equipment designed to produce downspout pipes from metal sheets or coils. The process involves shaping, bending, and cutting the raw material into the desired pipe form. These machines are equipped with features that allow manufacturers to customize dimensions and shapes, catering to various architectural needs. Typically, they ensure that each product is uniform in size and thickness, preserving the downspouts' integrity and effectiveness.

Features and Functions

Modern downspout pipe forming machines come with advanced technologies that enhance their functionality. Key features include

1. Automation Many of these machines are fully automated, significantly reducing labor costs and minimizing human error. Automation allows for quicker production times and consistent quality across large quantities of products.

2. Adjustability Manufacturers can easily adjust settings to accommodate different pipe sizes and materials, offering versatility in production. This adjustment capability means that a single machine can be used to create various downspout configurations, optimizing operational efficiency.

3. Precision With the use of computer numerical control (CNC) technology, downspout forming machines ensure that every pipe produced meets precise specifications. This level of accuracy is essential for proper fitting and effective water management.

4. Durability These machines are built to last, constructed from high-quality materials that can endure the rigors of continuous operation. This durability is key to maintaining production uptime and reducing maintenance costs.

5. Integration Many modern pipe forming machines can be integrated into a larger production line, allowing for a seamless transition from forming to finishing processes, such as painting or coating to resist corrosion.

Benefits of Using Downspout Pipe Forming Machines

Utilizing a downspout pipe forming machine presents several advantages for manufacturers in the construction industry

- Cost-Effectiveness The automation and efficiency of these machines lead to lower labor costs and higher productivity, ensuring better profit margins.

- Enhanced Quality The precision and consistency of machine-made downspouts result in a higher quality product, reducing waste due to errors or defects.

- Faster Production Quick turnaround times mean that not only can orders be fulfilled faster, but manufacturers can also respond more rapidly to market demands.

- Environmental Impact By optimizing material use and minimizing waste, these machines support more sustainable manufacturing practices.

Conclusion

As the construction industry continues to prioritize sustainability and efficiency, downspout pipe forming machines are becoming increasingly essential. By facilitating high-quality, precise production of essential components, these machines help ensure that buildings can effectively manage rainwater and maintain structural integrity. For manufacturers, investing in advanced downspout pipe forming technology is not only a move toward improved efficiency but also a step towards meeting the modern demands of the construction sector. As technology continues to advance, we can expect even greater innovations in the production of downspouts, ensuring their effectiveness for years to come.