The Evolution and Importance of Keel Manufacturing Machines

In the manufacturing and marine industries, keel manufacturing machines play a crucial role in the production of high-quality vessels. The keel is a pivotal component of a ship, acting as the backbone that provides structural integrity and stability in water. As the demand for advanced shipbuilding techniques increases, so too does the need for innovative keel manufacturing machines. This article explores the evolution, technology, and significance of these machines in modern shipbuilding.

Historical Context

The keel has been an essential part of ship design for centuries. Historically, the process of constructing a keel involved manual labor and a severe reliance on craftsmanship. Craftsmen meticulously shaped and fitted wood, which required immense skill and time. However, as maritime trade expanded and ship design grew more complex, the limitations of manual methods became apparent.

The advent of keel manufacturing machines fundamentally transformed the shipbuilding process. With the introduction of these machines, shipbuilders could achieve greater precision, speed, and efficiency. The move towards mechanization marked a significant turning point in the industry, paving the way for the mass production of vessels.

Technological Advancements

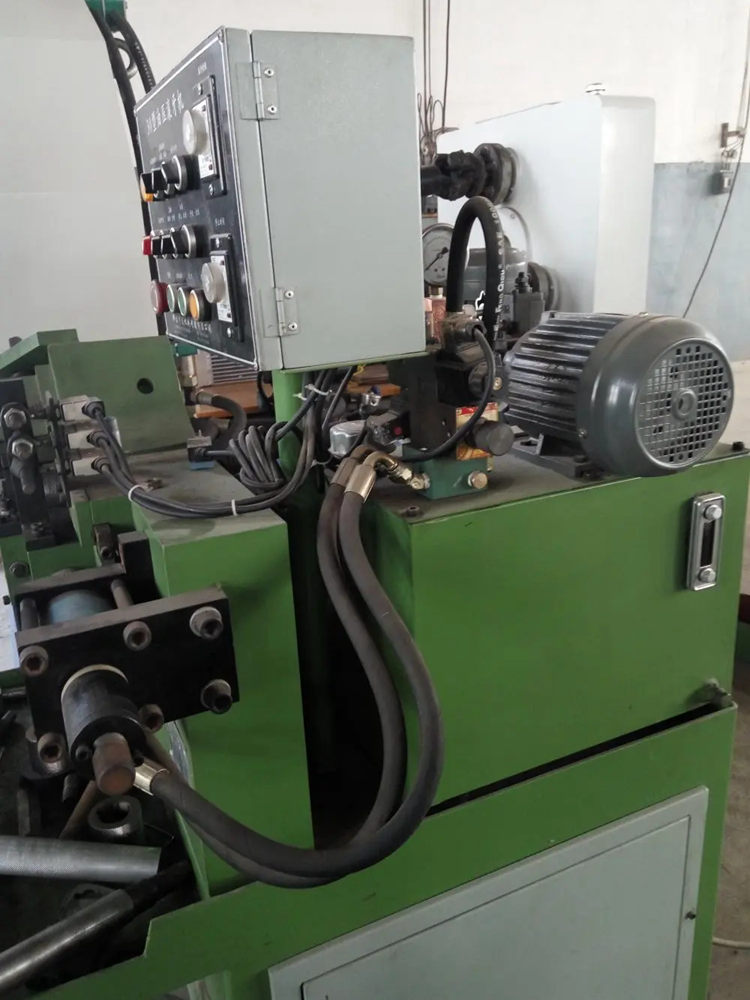

Modern keel manufacturing machines integrate a range of advanced technologies, including computerized numerical control (CNC), robotics, and advanced materials processing techniques. CNC machines allow for precise cuts and shapes, reducing human error and improving the overall quality of the manufactured keel. Robotics facilitate the handling and assembly of materials, increasing productivity and ensuring safety in often hazardous shipbuilding environments.

Moreover, advancements in materials science have introduced new composites and materials that enhance the performance and durability of keels. The combination of lightweight materials with robust properties ensures that ships are not only strong but also fuel-efficient. The machines are designed to work with these materials, automatically adjusting settings to optimize production.

The Impact on Shipbuilding Efficiency

The incorporation of keel manufacturing machines in shipyards has significantly impacted the efficiency of shipbuilding processes. Traditional shipbuilding was often hampered by lengthy timelines and labor-intensive methods. With advanced machinery, shipbuilders can produce keels and other components at a fraction of the time previously required. This efficiency translates into shorter turnaround times for vessel delivery, enabling companies to meet the growing demands of global trade.

Furthermore, the automation of keel manufacturing minimizes labor costs and reduces the likelihood of workplace injuries. With machines handling the more dangerous tasks, skilled workers can focus on overseeing operations, quality control, and fine-tuning designs. This shift not only protects workers but also enhances job satisfaction as employees engage in more strategic roles.

Environmental Considerations

In recent years, the shipbuilding industry has placed a greater emphasis on sustainability. Keel manufacturing machines are increasingly designed with eco-friendly processes in mind. Many machines now utilize energy-efficient techniques and work with sustainable materials, contributing to a reduction in the environmental impact of shipbuilding. Moreover, precise manufacturing processes minimize waste, further aligning with global sustainability goals.

Conclusion

Keel manufacturing machines represent a cornerstone of modern shipbuilding technology. Their ability to enhance efficiency, improve precision, and promote sustainability has revolutionized how vessels are designed and produced. As the maritime industry continues to evolve, the importance of these machines will only grow, underpinning the future of shipbuilding and ensuring that vessels are better equipped to navigate the challenges of the open seas.

In conclusion, keel manufacturing machines are not just mechanical devices; they embody the seamless integration of technology and craftsmanship, reflecting the spirit of innovation that drives the maritime industry forward. The ongoing advancements in this field promise to deliver even more robust and efficient shipbuilding processes, sailing us into a new era of maritime excellence.