The Advantages of CZ Purlin Forming Machines for Modern Construction

In the ever-evolving construction industry, efficiency and precision are crucial. Among the numerous innovations, the CZ purlin forming machine stands out as a transformative solution for metal building projects. This specialized machinery allows for the rapid production of C and Z-shaped purlins, which are essential components in steel structures. This article explores the features, advantages, and applications of CZ purlin forming machines, emphasizing their significant role in modern construction.

Understanding CZ Purlins

Purlins are horizontal beams used in the framework of buildings, primarily to support roofing and wall panels. The 'C' and 'Z' shapes refer to the cross-sectional profile of these purlins. C purlins are typically used in situations where the purlin acts primarily as a support beam, while Z purlins can be lapped on top of each other for better structural integrity. Both shapes contribute to the overall strength and stability of a building, and their specifications can vary based on the requirements of a project.

The Functionality of CZ Purlin Forming Machines

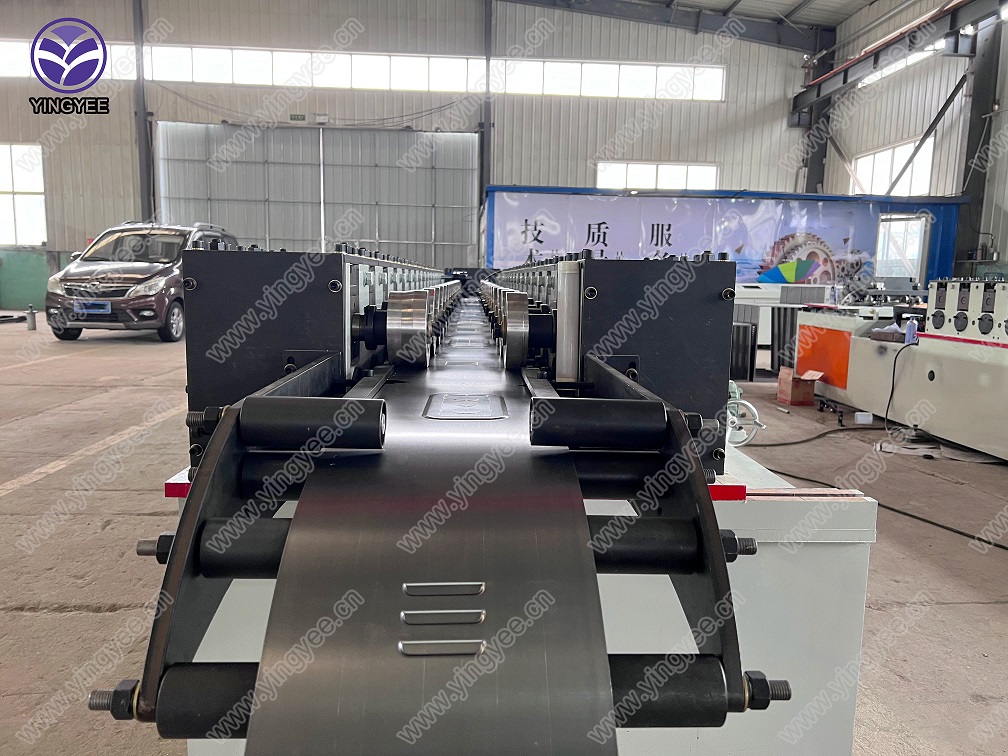

CZ purlin forming machines are advanced devices designed to automate the manufacturing of these structural components. They work by feeding steel coils into the machine, which then shapes them into the desired C or Z profile through a series of rollers and forming processes. Many modern machines are equipped with a computerized control system, allowing operators to easily switch between different sizes and shapes of purlins with minimal downtime.

This flexibility is one of the defining features of CZ purlin forming machines. They can produce purlins of various dimensions, thicknesses, and lengths, accommodating the specific needs of different construction projects. Additionally, some models integrate cutting systems that allow for precise length customization, enhancing the machine's versatility.

Advantages of Using CZ Purlin Forming Machines

1. Cost Efficiency One of the most significant benefits of using CZ purlin forming machines in construction is cost savings. By automating the manufacturing process, labor costs are reduced, and material wastage is minimized. This leads to lower overall project costs, making it an attractive option for contractors.

2. Speed Traditional methods of producing purlins can be time-consuming. However, CZ purlin forming machines can produce high volumes of purlins quickly. This accelerated production rate means that construction projects can progress more rapidly, meeting tight deadlines without compromising quality.

3. High Precision The automation offered by these machines ensures that each purlin is manufactured to precise specifications. Consistency in manufacturing is critical in construction to ensure structural integrity, and CZ purlin forming machines excel in delivering uniform products.

4. Easy Operation Modern CZ purlin forming machines come with user-friendly interfaces and automated controls. Operators can easily set parameters for different profiles and lengths, enabling quick changes without extensive retraining or technical expertise.

5. Durability and Strength The quality of products made from CZ purlin forming machines is often superior to manual or less sophisticated production methods. The machine ensures that the purlins maintain their structural integrity, resulting in durable and reliable building materials.

Applications in the Construction Industry

CZ purlins are widely used in various applications beyond conventional construction. They are essential components in the building of warehouses, factories, agricultural buildings, and even residential homes. Their flexibility allows for a wide range of architectural designs, and they are often used in combination with other materials to create hybrid structures that benefit from both steel's strength and other materials' aesthetic qualities.

Conclusion

The advancements in CZ purlin forming machines represent a pivotal shift in construction methodologies. With their ability to produce high-quality, cost-effective, and precise purlins rapidly, these machines enhance project efficiency and quality. As the construction industry continues to embrace innovation, CZ purlin forming machines will undoubtedly play a significant role in shaping the future of building design and construction, ensuring structures are not only strong but also efficiently constructed to meet modern demands.