Understanding Three Rollers Thread Rolling Machines

Thread rolling is a widely used manufacturing process for producing high-strength threads on cylindrical workpieces. Among the various types of machines available, the three rollers thread rolling machine stands out for its efficiency and precision. This article explores the design, operational principles, applications, and advantages of three rollers thread rolling machines.

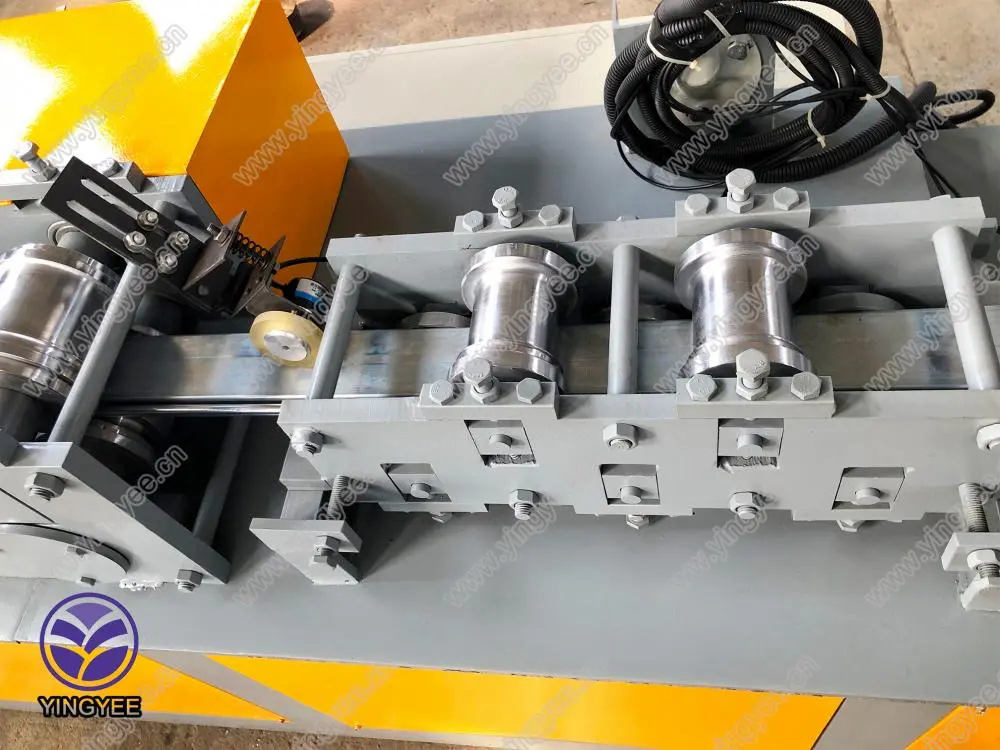

Design and Mechanism

A three rollers thread rolling machine consists of three rolls arranged in a triangular configuration. In this setup, two rolls are placed on top, while the third roll is positioned below them. The workpiece, typically a metal rod, is fed through the rolls, and as it passes between them, the threads are formed through plastic deformation. The top two rolls are driven by motors, which rotate them in opposite directions while the bottom roll acts as a stationary support.

This rolling process does not cut the material; instead, it reshapes it, making it an essential method for creating threads in materials ranging from steel to aluminum. The machine is capable of producing different thread profiles, such as coarse, fine, or specialized threads, depending on the specifications of the rolls.

Operational Principles

The operational efficiency of a three rollers thread rolling machine is attributed to its design and the mechanics involved in the process. When the rolls rotate, they exert pressure on the blank workpiece, causing the material to flow outward and fill the spaces of the thread profile. The force required to carry out this process is significantly less than that required by traditional cutting methods, as material is deformed rather than removed.

Commonly, the rolling speed, pressure exerted by the rolls, and the temperature of the material are regulated to achieve optimal results. This allows for high production rates and consistent quality in thread formation, making it suitable for mass production environments.

Applications

Three rollers thread rolling machines are employed across various industries, including automotive, aerospace, construction, and manufacturing. They are particularly vital for producing components such as bolts, screws, and studs that require high tensile strength and precise threading. The automotive industry, for instance, relies on these machines for producing thousands of fasteners that meet strict quality standards.

Moreover, the flexibility of three rollers thread rolling machines allows them to cater to customized orders where specific thread types or sizes are necessary, enabling manufacturers to meet diverse customer demands.

Advantages

One of the primary advantages of using three rollers thread rolling machines is their ability to produce threads with enhanced strength and durability. The cold working process not only improves the mechanical properties of the material but also leads to a finer surface finish compared to conventional machining methods.

Additionally, these machines are known for their efficiency; they can produce high volumes of threaded products in a shorter amount of time while consuming less energy. The reduction in material waste, as the process does not cut away any material, also contributes to lower operational costs.

In conclusion, three rollers thread rolling machines represent a significant advancement in the field of metalworking, providing manufacturers with an efficient, economical, and high-quality method for producing threaded components. Their versatility and performance make them indispensable tools in various industries, paving the way for innovation and reliability in threaded product manufacturing.