Understanding Steel Coil Straighteners An Essential Tool in Metal Processing

Steel coil straighteners play a crucial role in the metal processing industry. The importance of these machines can be attributed to their ability to convert coiled steel into flat sheets, a form that is easier to handle, process, and utilize in various applications. When dealing with rolled steel, imperfections such as warping, uneven edges, or residual stress can compromise the quality of the final products. A steel coil straightener addresses these issues, ensuring that the end material meets the stringent requirements of modern manufacturing.

The Working Principle of Steel Coil Straighteners

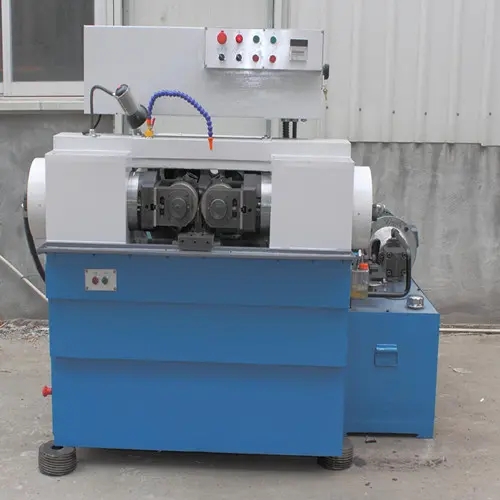

Steel coil straighteners utilize a series of rollers to correct distortions in the coil. As the coiled steel passes through these rollers, each roller exerts pressure on the material, flattening it gradually. The alignment and spacing of the rollers are adjustable to suit different thicknesses and types of steel, allowing for flexibility in operation. This process not only straightens the steel but also helps eliminate any internal stresses that may have developed during the rolling process.

The technology behind steel coil straighteners has evolved significantly over the years. Modern machines are equipped with advanced features, including digital controls and automated feeding systems, enhancing precision and efficiency. This level of automation reduces the need for manual intervention and minimizes errors, driving productivity up in manufacturing operations.

Benefits of Using a Steel Coil Straightener

The advantages of incorporating a steel coil straightener in production lines are numerous

1. Improved Material Quality Straightening steel coils results in high-quality flat sheets that are free from defects. This is crucial for industries that require precise measurements and tolerances, such as automotive and aerospace manufacturing.

2. Enhanced Processing Flat steel sheets are easier to handle during further processing—whether that be cutting, welding, or forming. This streamlining of pre-production steps translates to increased efficiency in the overall manufacturing workflow.

3. Reduced Scrap Rates By achieving better straightness and surface quality, manufacturers can significantly reduce waste. This not only cuts costs but also contributes to more sustainable production practices.

4. Versatility Steel coil straighteners can accommodate a variety of coil types and thicknesses. This versatility makes them an invaluable asset in facilities that work with multiple steel grades and sizes.

5. Consistency in Production By ensuring that each sheet of steel meets specific standards, straighteners provide consistency in the output. This reliability is critical when producing components that must fit together seamlessly, such as in automotive assemblies or machinery.

Conclusion

In conclusion, steel coil straighteners are indispensable tools in the metal processing landscape. They not only enhance the quality and usability of steel but also optimize manufacturing efficiency. As industries continue to evolve, the demand for high-quality, accurately processed steel will only increase, solidifying the steel coil straightener's place as a critical piece of equipment. Investing in modern, efficient straightening technology will undoubtedly yield long-term benefits for manufacturers, paving the way for innovation and growth in metalworking industries.