The Importance of C/Z Purlin Automatic Lines in Modern Construction

In the realm of modern construction, efficiency and precision are paramount. One crucial component that aids in achieving these objectives is the C/Z purlin automatic line. As construction methods evolve and the demand for high-quality structures increases, the integration of automated systems in the manufacturing of building materials becomes increasingly significant. This article explores the functionality, advantages, and implications of C/Z purlin automatic lines in the construction industry.

Understanding C/Z Purlins

C/Z purlins are structural members used in steel construction, primarily in buildings and industrial structures. The 'C' and 'Z' refer to the shape of the purlins, with 'C' purlins featuring a C-like profile and 'Z' purlins resembling a Z-like shape. These components play a vital role in providing support to roofs and wall systems, acting as a framework for the secondary structural elements. They are widely appreciated for their lightweight, strength, and versatility.

The Automation Advantage

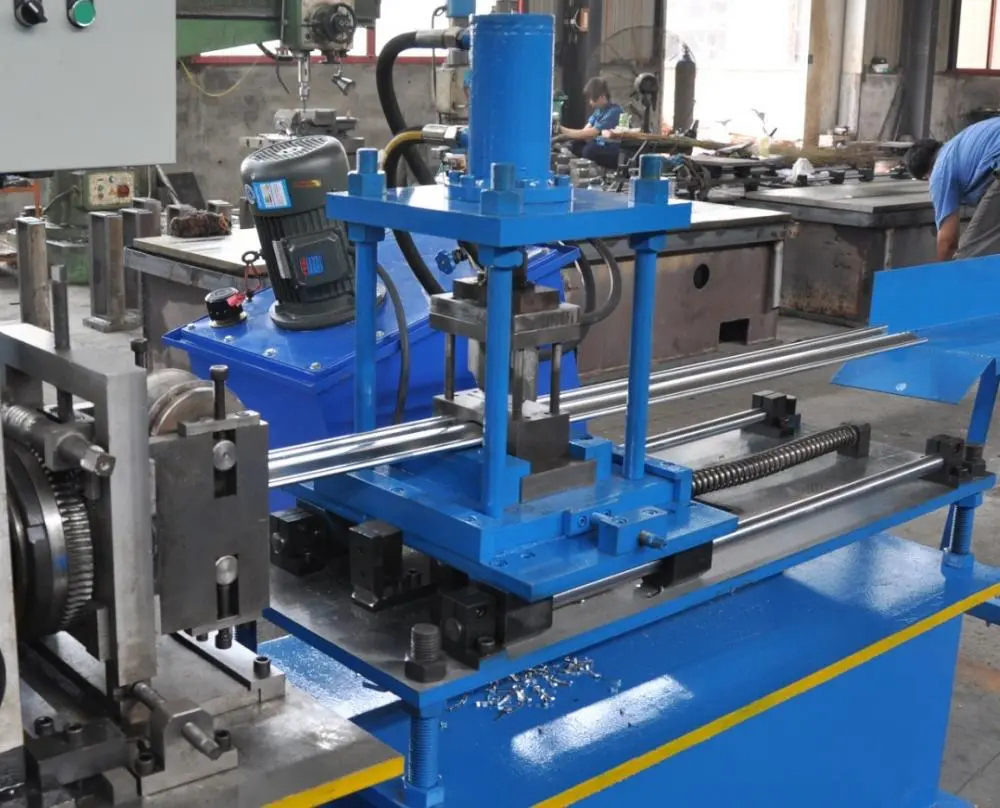

The introduction of automatic lines for the production of C/Z purlins revolutionizes the manufacturing process. By employing advanced technology, these automatic lines ensure precision in cutting, punching, and forming. The result is consistently high-quality products that meet the stringent demands of the construction industry. Automation significantly reduces human error and labor costs, making the production process more efficient.

Key Features of C/Z Purlin Automatic Lines

1. High Efficiency Automatic lines are designed to operate continuously, maximizing production rates while minimizing downtime. This efficiency is crucial for construction projects operating on tight schedules.

2. Precision and Quality Control Automated systems utilize advanced sensors and control systems to ensure that each purlin is manufactured to exact specifications. This level of precision is vital for structural integrity and compliance with building codes.

3. Customization The flexibility of automatic lines allows for the production of customized purlins to meet specific project requirements. Whether it's unique dimensions or additional features, automated systems can adapt accordingly.

4. Reduced Waste With precise cutting and forming processes, automatic lines significantly reduce material waste. This not only cuts costs but also promotes sustainability within the construction industry.

5. Safety Enhancements Automation reduces the need for manual labor in potentially hazardous environments, thereby enhancing worker safety. Automated processes typically require fewer workers on-site, minimizing the risk of accidents.

Implications for the Construction Industry

The adoption of C/Z purlin automatic lines has far-reaching implications for the construction industry. Firstly, it leads to faster project completion times, enabling contractors to meet deadlines more effectively. Secondly, the cost savings achieved through reduced labor and material waste can be reinvested in other areas of a project, facilitating innovation and growth.

Moreover, the consistent quality of C/Z purlins produced by automatic lines ensures that buildings are safer and more durable. As the industry continues to prioritize sustainable practices, the reduced waste generated by automation also aligns with the growing demand for eco-friendly construction methods.

Future Trends

As technology continues to advance, we can anticipate further innovations in the field of automated manufacturing. Future C/Z purlin automatic lines may incorporate artificial intelligence and machine learning to enhance production efficiency and quality control even more. Additionally, increased integration with building information modeling (BIM) systems can provide real-time data and analytics, optimizing production schedules and reducing lead times.

Conclusion

In conclusion, C/Z purlin automatic lines play a pivotal role in the modern construction landscape. By enhancing efficiency, precision, and safety, these automated systems not only meet the current demands of the industry but also pave the way for future advancements in construction technology. As stakeholders continue to embrace automation, the potential for streamlined processes and improved product quality will redefine how we approach steel construction in the years to come. Embracing this evolution will not only benefit manufacturers and contractors but ultimately lead to safer, more efficient buildings that meet the needs of communities worldwide.