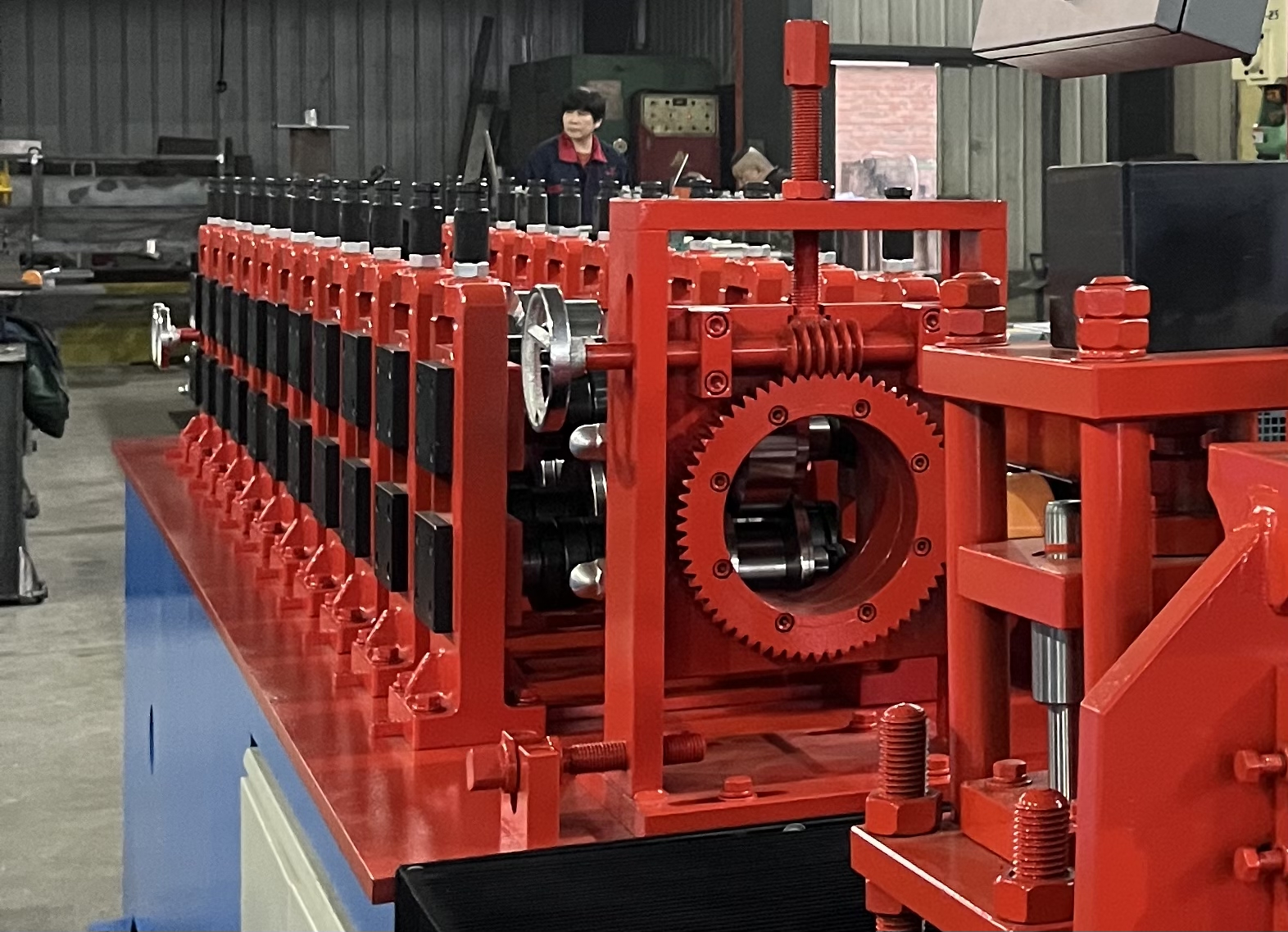

Customized Angle Stud and Track Roll Forming Machine

In the construction and manufacturing industries, the demand for precision-engineered components is ever-growing. One such essential machine that facilitates the production of high-quality framing materials is the customized angle stud and track roll forming machine. This machinery specializes in crafting wall angle components, which are critical in the erection of walls and ceilings.

The Role of Roll Forming Machines

Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is passed through a series of rollers. Each set of rollers shapes the metal into a specific profile. This technique is highly efficient, allowing for production runs of high volumes with minimal waste. The customized angle stud and track machines specifically cater to producing components like C-channels and main channels, which are commonly used in commercial and residential construction.

Advantages of Customization

One of the primary benefits of investing in a customized roll forming machine is its ability to meet the unique specifications of different projects. The design of these machines can be tailored to produce various sizes and profiles of angle studs and tracks, allowing manufacturers to cater to specialized requests. This level of customization ensures that the materials fit the precise requirements of any building project, thereby enhancing structural integrity and aesthetic appeal.

Technological Innovations

Modern roll forming machines incorporate advanced technology, such as computer numerical control (CNC) and automation, which increases efficiency and accuracy. CNC systems allow engineers to program the exact dimensions and angles required for different profiles, reducing human error and production time. Furthermore, automated features minimize labor costs and enhance safety in the production environment.

Production Efficiency

The efficiency of customized angle stud and track roll forming machines significantly impacts lead times and overall productivity. With the capability to produce long lengths of continuous profiles, manufacturers can reduce the time spent on cutting and handling materials. Additionally, these machines often include features for in-line punching, notching, and cutting, further streamlining the production process. This integration of multiple operations reduces the need for secondary processes, minimizing labor and material costs.

Environmental Considerations

In today’s eco-conscious environment, the sustainable production of building materials is crucial. Roll forming machines, particularly those employing advanced technology, can contribute to reduced material waste and energy consumption. The precision of custom machines means less scrap material is produced, which not only optimizes resources but also supports environmental sustainability efforts in the construction industry.

Conclusion

The customized angle stud and track roll forming machine is an invaluable asset for manufacturers looking to produce high-quality, precision-engineered framing materials. With its advanced technology, efficiency, and adaptability to specific project requirements, this machine plays a vital role in meeting the demands of modern construction. As the industry continues to evolve, the importance of such innovative machinery will undoubtedly grow, paving the way for a more structured and sustainable future in building and construction.