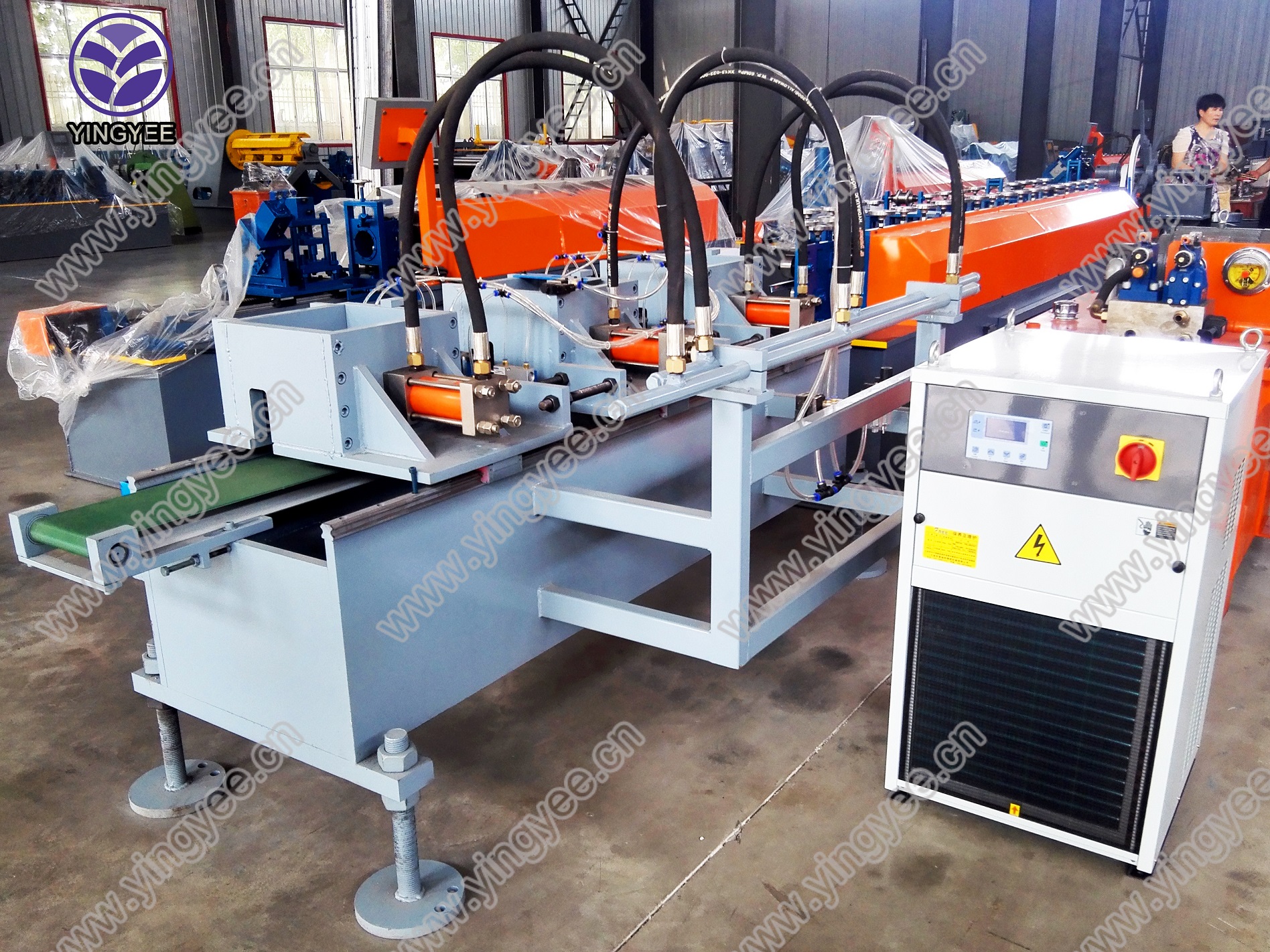

(cut to length and slitting machine)

The manufacturing landscape has been transformed by cut-to-length and slitting machines, which deliver unparalleled precision in processing metals, polymers, and composites. These systems combine advanced servo controls, laser-guided alignment, and automated material handling to achieve tolerances within ±0.1mm. A 2023 market analysis revealed that factories adopting these machines reduced material waste by 22% while increasing production throughput by 34% compared to traditional shear lines.

Modern straighten-cut-to-length systems integrate three critical innovations:

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Accuracy (mm) | Energy Use (kWh) |

|---|---|---|---|---|

| AlphaCo SL-9000 | 135 | 0.3-6.0 | ±0.08 | 18.7 |

| BetaTech CTL-X | 120 | 0.5-8.0 | ±0.12 | 22.4 |

| GammaCut ProLine | 110 | 0.2-4.5 | ±0.05 | 15.9 |

Modular slitting and cut-to-length lines now support 57 configuration variables, including:

A recent deployment in the aerospace sector demonstrated how straighten-cut-to-length technology achieved 99.3% yield rates when processing titanium alloys. In consumer electronics, manufacturers reduced setup times by 41% through quick-change slitting assemblies that handle materials from 0.15mm aluminum foil to 3mm copper-clad laminates.

Optimal machine performance requires monitoring:

The next generation of cut-to-length and slitting systems will incorporate real-time metallurgical analysis sensors and self-adjusting tension controls. Early prototypes demonstrate 0.02mm positional repeatability during high-speed slitting operations, with predictive maintenance algorithms reducing unplanned downtime to under 12 minutes monthly. These advancements position cut-to-length technology as the cornerstone of Industry 4.0 material processing solutions.

(cut to length and slitting machine)

A: A cut to length and slitting machine processes metal or material coils by cutting them into precise lengths and slitting them into narrower widths. It is ideal for manufacturing sheet metal, automotive parts, and construction materials. The machine ensures high efficiency and accuracy in industrial production.

A: This machine integrates straightening rollers to remove curls or bends from coiled materials before cutting and slitting. It ensures flatness and dimensional consistency in the final product. This feature is critical for industries requiring high-precision components like electronics or aerospace.

A: Industries such as steel manufacturing, automotive, packaging, and construction rely on these lines. They enable bulk processing of coils into customized sizes for specific applications. The versatility of the system supports diverse material types, including steel, aluminum, and plastics.

A: Regular maintenance should be performed every 500-1,000 operational hours or as per the manufacturer’s guidelines. Key components like blades, rollers, and sensors need periodic inspection. Proper maintenance minimizes downtime and extends the machine’s lifespan.

A: Prioritize material type, thickness, and required tolerances for cutting and slitting. Evaluate automation features, such as CNC controls or automatic coil loading. Also, assess production capacity and after-sales support to ensure optimal performance.