The Evolution of Stud and Track Making Machines

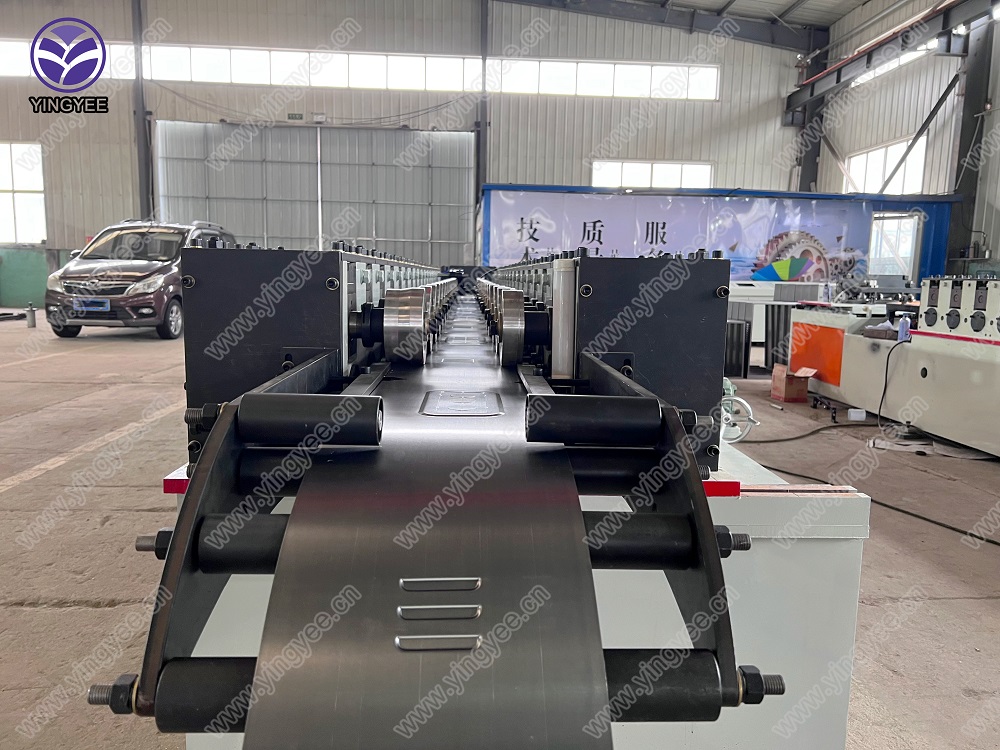

In the ever-evolving landscape of manufacturing, the introduction of stud and track making machines has revolutionized the way industries produce essential components for various applications. These machines are designed to efficiently create studs and tracks, which are crucial elements in construction, automotive, and manufacturing sectors.

Studs, which are short metal rods used in construction for framing, and tracks, which are the supporting structures for various applications, have traditionally been manufactured through labor-intensive processes. However, the advent of automated making machines has significantly transformed the production line. These machines not only increase output but also enhance precision, reducing the likelihood of errors that can occur in manual production.

The modern stud and track making machines leverage advanced technologies such as CNC (Computer Numerical Control) systems, allowing for automated control of the machining process. This automation facilitates the production of complex designs with ease, catering to the diverse needs of industries. Additionally, these machines often come equipped with software that can simulate production, helping manufacturers optimize their workflows and reduce waste.

One of the significant advantages of using stud and track making machines is their ability to produce high volumes efficiently. This is particularly advantageous in industries that require consistent and rapid production rates. As the demand for construction materials and automotive parts grows, manufacturers are turning to these machines to meet the ever-increasing market needs.

Moreover, the integration of robotics in stud and track production has further streamlined processes. Robotic arms can perform tasks such as loading and unloading materials, aiding in quality control inspections, and even packaging finished products. This not only minimizes human error but also enhances safety within the production environment.

Sustainability is another vital aspect driving the adoption of modern stud and track making machines. Many manufacturers are now opting for machines that minimize energy consumption and reduce material waste, aligning with global efforts to promote environmentally friendly practices.

In conclusion, the development of stud and track making machines marks a significant advancement in manufacturing technology. By enhancing efficiency, precision, and sustainability, these machines are set to play an essential role in meeting the growing demands of various industries. As technology continues to progress, we can anticipate even more innovative features and capabilities emerging in this space, further transforming the way we approach manufacturing.