Quick Changeable C/Z Purlin Roll Forming Machine Revolutionizing the Steel Structure Industry

In the construction sector, the demand for versatile and efficient steel components has never been higher. Among the essential elements in establishing robust structures are purlins, which serve as horizontal supports for roofs or walls. The emergence of the Quick Changeable C/Z Purlin Roll Forming Machine has significantly transformed the production of these vital components, offering a range of benefits that cater to the evolving needs of builders and manufacturers.

What is a C/Z Purlin?

C/Z purlins are structural members used in a variety of building applications. Their shapes—either C or Z profiles—make them ideal for supporting roofs and walls, as they can easily accommodate changes in load and support various types of cladding systems. The choice between C and Z profiles typically depends on the specific design requirements of a project, which necessitates a flexible manufacturing solution.

The Need for Quick Changeability

Traditional roll forming machines were often limited in their capabilities, requiring significant time and effort to switch between different product types. As a result, manufacturers struggled with long downtimes and inefficiencies when they needed to adapt their production lines for varying project requirements. The Quick Changeable C/Z Purlin Roll Forming Machine addresses this issue head-on, allowing for rapid adjustments in profile configurations without extensive re-tooling.

With the ability to switch between C and Z purlin production within a matter of minutes, companies can significantly reduce production downtime. This flexibility enables manufacturers to tackle diverse projects—from lightweight industrial structures to heavy-duty commercial buildings—without the constraints of rigid manufacturing processes.

Key Features of the Quick Changeable Roll Forming Machine

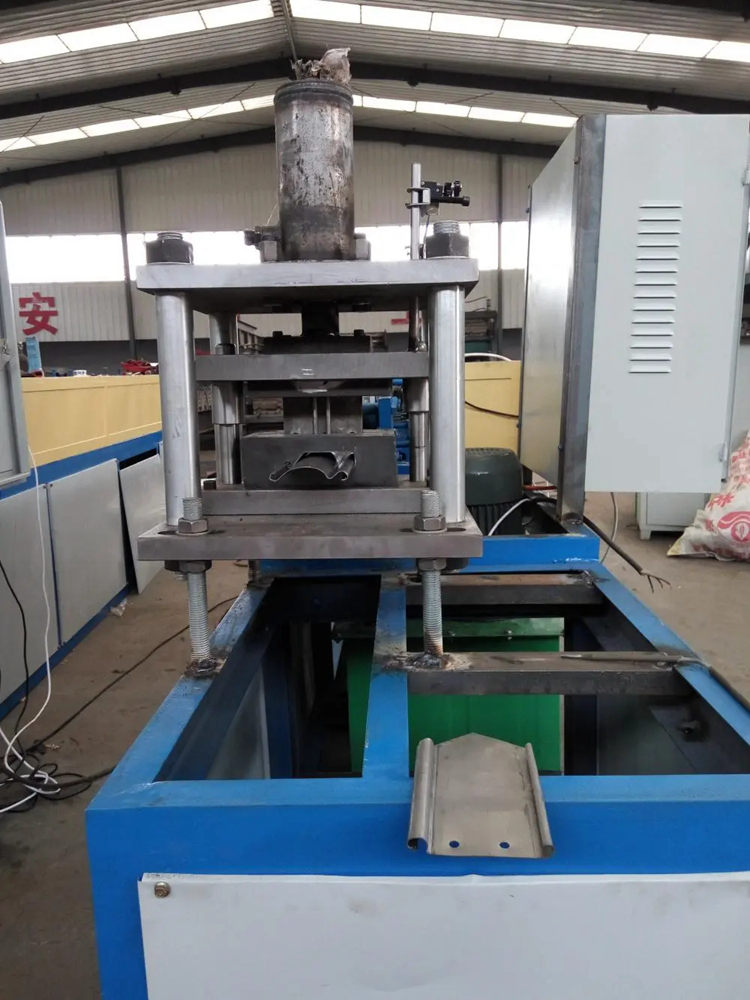

1. Interchangeable Tooling The standout feature of this machine is its interchangeable tooling system, which allows operators to easily switch the die and roll sets according to specific requirements. This adaptability is crucial for meeting varying customer specifications without major interruptions in production.

2. Advanced Technology Integration Many modern roll forming machines integrate advanced technology such as CNC (Computer Numerical Control) systems. This technology enhances precision and repeatability in production, ensuring that each purlin meets stringent quality standards.

3. User-Friendly Interface Manufacturers often overlook the importance of ease-of-use, but a user-friendly interface allows operators to quickly set up the machine for different profiles. This efficiency not only saves time but also reduces the likelihood of human error during production.

4. Durable Construction Given the demanding nature of metal forming, these machines are built to withstand continuous use while maintaining high output capacity. The robustness of the machine ensures that it can handle the stress of forming operations without compromising performance or quality.

5. Energy Efficiency Modern roll forming machines are also designed with energy efficiency in mind. By optimizing power consumption, manufacturers can reduce operational costs while contributing to environmental sustainability.

Advantages for Manufacturers

The benefits of Quick Changeable C/Z Purlin Roll Forming Machines extend beyond improved production times. Manufacturers enjoy enhanced versatility, allowing them to rapidly respond to market fluctuations and client demands. Additionally, with reduced downtime and higher efficiency, overall production costs can be significantly lowered, granting companies a competitive edge in the steel structure market.

Moreover, these machines contribute to sustainability efforts by minimizing waste. Efficient material usage and the ability to produce various purlin types in smaller batches enable manufacturers to operate more eco-friendly production processes.

Conclusion

As the construction industry continues to evolve, the demand for innovative manufacturing solutions will also increase. The Quick Changeable C/Z Purlin Roll Forming Machine stands out as a game-changer, promoting flexibility, efficiency, and sustainability in purlin production. By adopting this cutting-edge technology, manufacturers can not only enhance their operational capabilities but also better serve the diverse needs of their clients, ensuring that they remain at the forefront of the steel structure industry.