Customized Angle Stud and Track Roll Forming Machine for Wall Angle Production

In the realm of modern construction, efficiency and precision play pivotal roles in determining the quality and durability of structures. Among the essential elements in building systems are studs and tracks, which form the backbone of framing systems for walls, ceilings, and roofs. The demand for customized components has led to innovations in manufacturing technology, particularly in roll forming machinery. One such advancement is the customized angle stud and track roll forming machine specifically designed for wall angle production.

Understanding Roll Forming

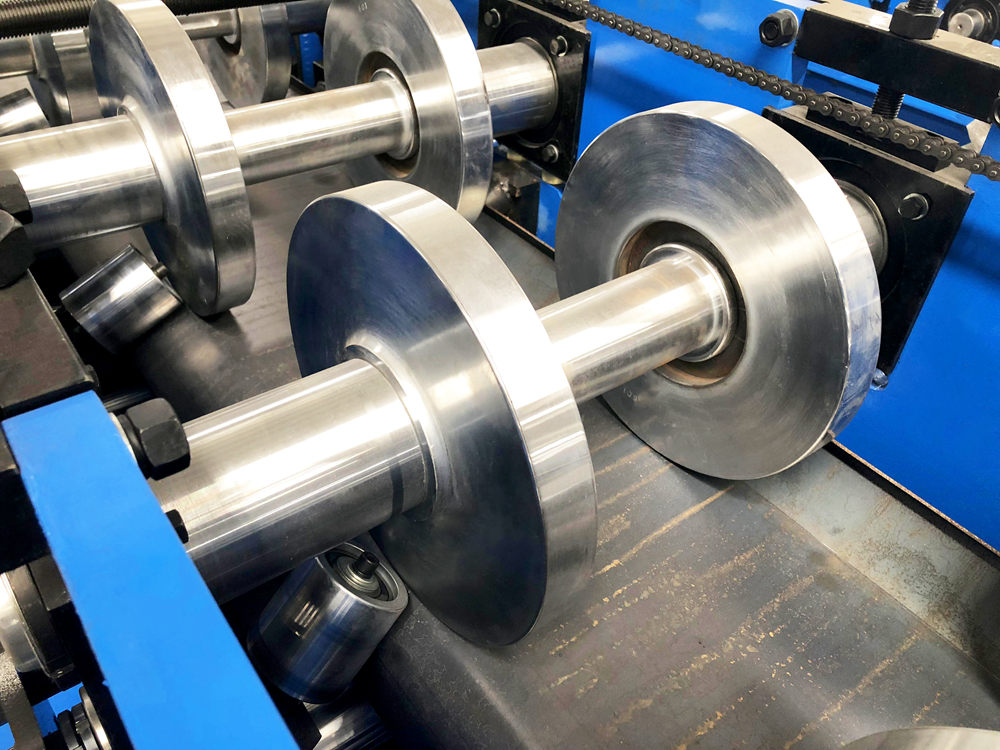

Roll forming is a continuous bending operation in which a long strip of sheet metal, usually in coil form, is passed through consecutive pairs of rolls. This process gradually shapes the material into a desired profile, such as that of an angle stud or track. Unlike traditional metal fabrication methods, roll forming can produce parts with uniform cross-sections over long lengths, reducing waste and ensuring consistency.

The Importance of Customized Solutions

Every construction project has unique requirements. Standard components may not suffice, prompting the need for customized solutions. A customized angle stud and track roll forming machine allows manufacturers to create products that cater to specific architectural designs and structural demands. This machine can be adjusted to produce varying sizes and shapes, enabling producers to meet client needs effectively.

Key Features of a Customized Roll Forming Machine

1. Versatile Design Capabilities A high-quality roll forming machine can be tailored to produce a variety of angles and profiles. Adjustments can be made to accommodate different gauge materials, ensuring versatility in production.

2. High Precision With advanced computer numerical control (CNC) technology, these machines achieve high precision in shaping components. This accuracy minimizes the need for secondary operations, thus speeding up the production process.

3. Efficient Production Process A well-engineered machine enhances production efficiency by maintaining constant speed and reducing downtime. High-speed operation enables manufacturers to keep up with demand while minimizing labor costs and material waste.

4. Ease of Operation and Maintenance User-friendly interfaces allow operators to easily adjust settings and monitor the production process. Additionally, simplified maintenance protocols ensure that the machine remains in optimal condition, reducing the risk of unexpected breakdowns.

5. Enhanced Safety Features Modern roll forming machines are equipped with safety mechanisms that protect operators during the manufacturing process. Emergency shutoff switches, protective guards, and intuitive controls contribute to a safer working environment.

Applications in Construction

The angle stud and track produced by these roll forming machines are essential components in framing systems. They serve as supports for wall systems, ceilings, and can also be utilized in partitions and other structural elements. The lightweight yet sturdy nature of these customized profiles allows for easy handling and installation, making them favorable for both residential and commercial construction.

Conclusion

The customized angle stud and track roll forming machine has revolutionized the construction industry by providing tailored solutions that meet diverse architectural needs. By focusing on precision, efficiency, and user-friendly operation, these machines not only enhance productivity but also ensure high-quality outputs. As the construction sector continues to evolve, the demand for innovative manufacturing techniques will keep driving advancements in roll forming technology, synonymous with quality and customization.