The Evolution and Importance of the Standing Seam Making Machine

In the world of modern construction and architectural design, efficiency and innovation play pivotal roles. One of the breakthroughs in this realm is the standing seam making machine, a technology that has transformed how metal roofing systems are produced and installed. Standing seam roofs, characterized by their interlocking seams that stand vertically above the plane of the roof, offer several advantages over traditional roofing methods, including durability, leak resistance, and aesthetic appeal. This article delves into the significance, functionality, advancements, and market prospects of standing seam making machines.

Understanding the Standing Seam Making Machine

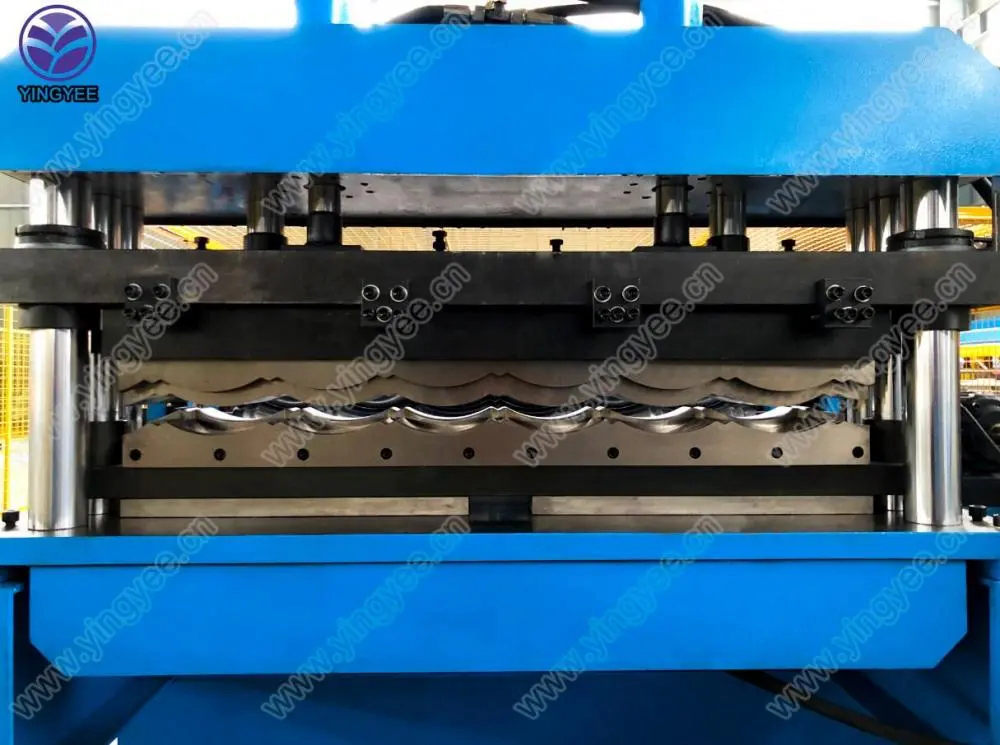

A standing seam making machine is a specialized piece of equipment designed to fabricate metal panels for roofing systems. These machines typically operate through a continuous roll-forming process, where flat sheets of metal, often aluminum or steel, are fed into the machine and transformed into panels with standing seams. These seams not only enhance the structural integrity of the roof but also facilitate effective water drainage.

The fundamental components of a standing seam making machine include a roller system that shapes the metal, cutting tools that define the lengths of the panels, and a control panel for precise operation. Modern machines integrate advanced technology, allowing for automation and reducing the need for manual labor, thereby increasing efficiency and consistency in production.

Advantages of Standing Seam Roofs

Standing seam roofs offer many benefits, which contribute to their increasing popularity in both residential and commercial projects. Firstly, the vertical seams effectively prevent water infiltration, making these roofs highly waterproof. This characteristic is especially vital in regions prone to heavy rainfall or snowfall.

Secondly, standing seam roofs provide thermal efficiency. The air space created between the roof and the underlying insulation allows for better temperature regulation, which can lead to significant energy savings. Furthermore, these roofs are resilient against wind uplift, making them ideal for areas susceptible to storms and hurricanes.

Additionally, the aesthetic versatility of standing seam roofs cannot be overlooked. Available in various colors and finishes, they can complement a range of architectural styles, from contemporary to traditional. Their sleek, modern look appeals to architects and home designers alike, contributing to their growing popularity.

Recent Advancements in Technology

As construction demands evolve, so do the capabilities of standing seam making machines. Recent advancements include the incorporation of smart technology, which allows for more precise control over the roll-forming process. Automated systems can now adjust parameters such as speed, temperature, and pressure based on the specific type of metal being used, optimizing production and ensuring consistent quality.

Moreover, developments in materials science have led to the use of lighter, more durable metals, enhancing the performance and longevity of the standing seam roofs. The integration of sustainable practices in manufacturing processes is also on the rise, reflecting a growing emphasis on environmental responsibility within the industry.

Market Trends and Future Prospects

The market for standing seam making machines is poised for growth. Factors driving this trend include an increasing demand for sustainable building practices, the rise in commercial construction projects, and the growing awareness of the long-term benefits associated with standing seam roofing.

Additionally, as the construction industry continues to recover and expand post-pandemic, investments in advanced machinery will likely rise. Manufacturers are anticipated to explore innovative designs that enhance efficiency and reduce costs, further solidifying the standing seam making machine's place in the market.

Conclusion

The standing seam making machine represents a significant advancement in the field of construction technology. With its ability to produce durable, efficient, and aesthetically pleasing roofing solutions, it plays a crucial role in shaping the future of architectural design. As the industry continues to evolve, standing seam roofs will undoubtedly remain a preferred choice, paving the way for continued innovation in roofing technologies. The ongoing development of standing seam making machines not only promises to improve productivity but also enhances the overall quality and sustainability of construction practices around the globe.