The Importance of Corrugated Sheet Rolling Machines in Modern Manufacturing

In the dynamic landscape of modern manufacturing, the significance of efficient production equipment cannot be overstated. Among the key players in this arena is the corrugated sheet rolling machine, a specialized tool that enhances the production of corrugated sheets utilized in diverse applications ranging from packaging to construction. This article explores the features, benefits, and operational principles of corrugated sheet rolling machines, as well as their impact on the manufacturing sector.

Understanding Corrugated Sheets

Before delving into the machines themselves, it’s essential to understand what corrugated sheets are. These sheets are made from a fluted layer of paper sandwiched between two liners, creating a structure that is both lightweight and robust. The unique design of corrugated sheets allows for excellent compressive strength, making them ideal for transporting goods, providing structural support in buildings, and serving numerous other purposes.

The corrugated sheet rolling machine plays a pivotal role in the production of these sheets, as it efficiently transforms raw materials into finished corrugated products.

Features of Corrugated Sheet Rolling Machines

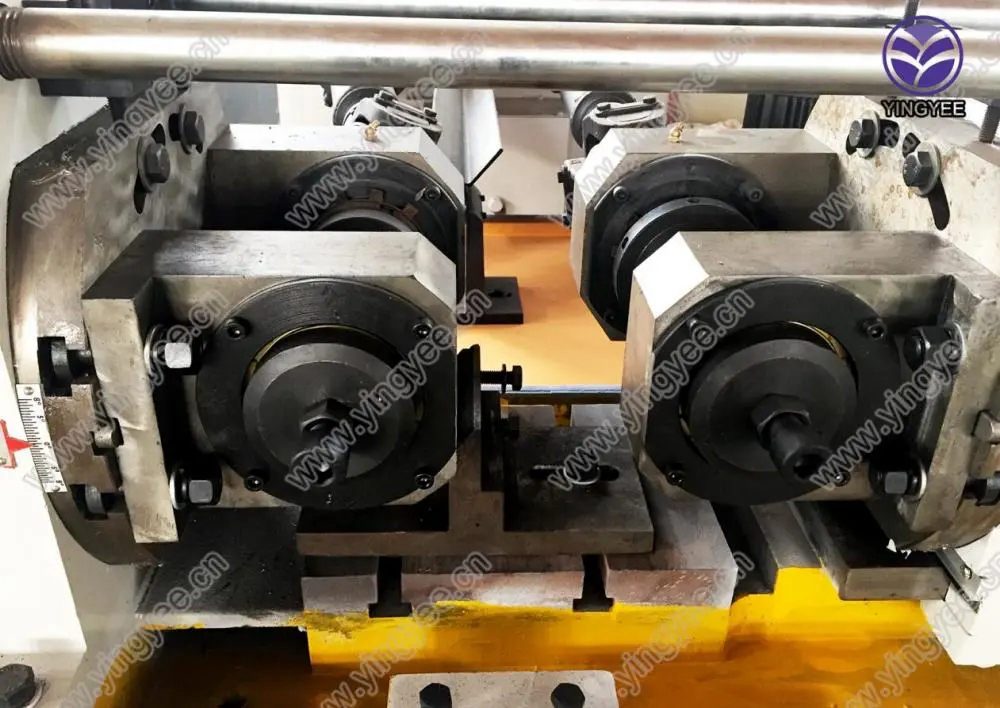

Corrugated sheet rolling machines are equipped with advanced features designed to enhance productivity and quality. Typically, these machines include multiple rollers that process metal or paper sheets into corrugated forms. The most notable features include

1. Adjustable Rollers This feature allows for customization of sheet thickness and wave height, accommodating various production needs and specifications. 2. Control Systems Modern machines often come with computerized control systems that enhance precision in production. Operators can program the machine for specific parameters, ensuring consistency and reducing wastage.

3. Speed and Efficiency These machines are designed to operate at high speeds, significantly reducing the time taken to produce large quantities of corrugated sheets. This efficiency leads to increased output and profitability for manufacturers.

4. Durability and Maintenance Built with high-quality materials, corrugated sheet rolling machines are designed to withstand continuous use. Regular maintenance protocols can be implemented easily to ensure longevity and optimal performance.

5. Automation Automation features, such as automatic feeding systems and cutting tools, minimize manual labor and improve safety in the production process.

Benefits of Using Corrugated Sheet Rolling Machines

The advantages of employing corrugated sheet rolling machines in manufacturing are manifold

1. Cost-Effectiveness By enhancing production efficiency and reducing waste, these machines contribute to lower overall manufacturing costs. They enable businesses to meet market demands swiftly and effectively.

2. Versatility Corrugated sheet rolling machines can produce a variety of sheet sizes and designs, making them suitable for different applications. This versatility allows manufacturers to cater to diverse industries, from packaging to construction.

3. Quality Assurance The precision capabilities of these machines ensure that every sheet produced meets specified standards, leading to higher-quality end products. This reliability fosters customer trust and satisfaction.

4. Scalability As businesses grow, their production needs can change. Corrugated sheet rolling machines offer the flexibility to scale operations, enabling manufacturers to expand their product lines without significant overhauls in equipment.

The Future of Corrugated Sheet Rolling Machines

With advancements in technology, the future of corrugated sheet rolling machines looks promising. Innovations in artificial intelligence and machine learning are expected to further enhance the efficiency and accuracy of these machines. Integrating smart technology can allow for real-time monitoring and predictive maintenance, further reducing downtime and extending equipment life.

In addition, as eco-friendly practices gain traction, the development of machines that utilize sustainable materials will become increasingly important. Manufacturers are likely to invest in machines capable of producing recycled corrugated sheets, aligning production with global sustainability goals.

Conclusion

In the ever-evolving world of manufacturing, corrugated sheet rolling machines play a vital role in creating one of the industry's most versatile and essential products. Their innovative features significantly enhance production efficiency, offering cost-effective and high-quality solutions for various applications. As technology continues to advance, these machines will undoubtedly become even more integral to the manufacturing landscape, ensuring that businesses can meet the demands of the future while prioritizing sustainability and efficiency.