The Rise of Corrugated Panel Lines Innovations in Manufacturing

In recent years, the manufacturing industry has witnessed significant advancements, particularly in the production of corrugated panels. Corrugated panel lines play a crucial role in the efficient and effective manufacturing of these versatile materials, which are widely used across various sectors including construction, packaging, and transportation. This article explores the importance, technology, and benefits of corrugated panel lines in today's market.

Understanding Corrugated Panels

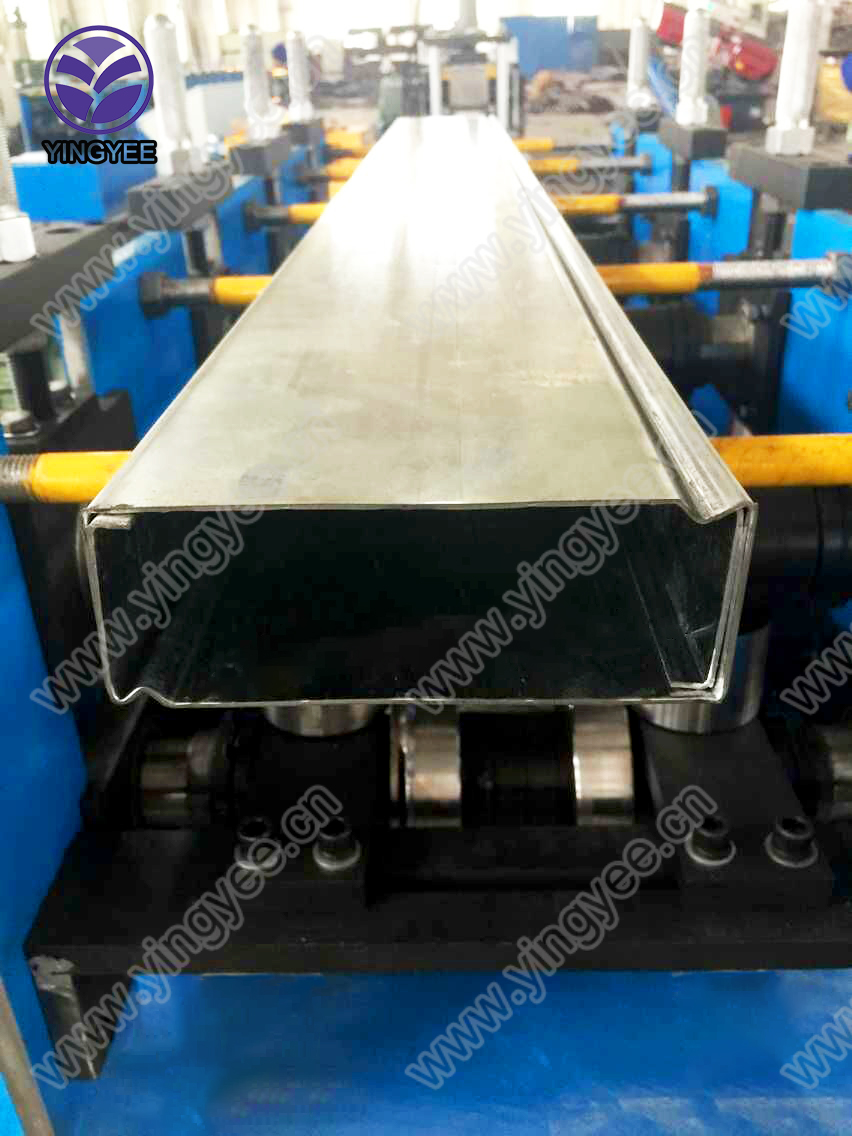

Corrugated panels are sheets of material with a distinctive wave-like structure, providing them with enhanced strength and durability compared to flat panels. Commonly made from materials such as cardboard, metal, or plastic, these panels are lightweight, yet they offer excellent resistance to impact and compression. Their structure makes them ideal for creating packaging boxes, roofing sheets, wall panels, and various other applications.

The Importance of Corrugated Panel Lines

The efficiency of corrugated panel production is largely reliant on specialized machinery known as corrugated panel lines

. These lines streamline the manufacturing process by integrating several stages, including material feeding, shaping, cutting, and stacking. By automating these processes, manufacturers can significantly reduce lead time and enhance productivity. This is particularly important in a competitive market where time and cost-effectiveness can dictate business success.Innovations in Technology

Recent advancements in technology have further refined the functionality of corrugated panel lines. The incorporation of computer numerical control (CNC) systems has enabled precise measurements and cuts, ensuring that panels adhere to strict industry standards. Additionally, the use of robotics in these lines has improved the efficiency of tasks such as stacking and packing, reducing manual labor and minimizing the risk of injuries.

Furthermore, smart manufacturing technologies, such as the Internet of Things (IoT), have been adopted in corrugated panel production. This allows for real-time monitoring of machinery and production processes, facilitating predictive maintenance and minimizing downtime. The integration of data analytics enables manufacturers to optimize their operations and respond swiftly to shifts in demand or production issues.

Benefits of Using Corrugated Panel Lines

The deployment of corrugated panel lines brings numerous benefits. Firstly, they significantly enhance production speed, allowing businesses to meet market demands more effectively. Secondly, the consistency in quality achieved through standardized processes leads to higher customer satisfaction and reduced waste from defective products. Additionally, the automation of labor-intensive tasks can lead to considerable cost savings, enabling companies to invest in other areas of their operations.

Lastly, the versatility of corrugated panels means that companies can cater to a wide range of applications, thus opening new markets and revenue streams. Whether in the construction industry or for packaging solutions, the ability to produce high-quality corrugated panels efficiently gives businesses a competitive edge.

Conclusion

As the manufacturing landscape continues to evolve, corrugated panel lines stand at the forefront of innovation. They are not only instrumental in enhancing production efficiency but also play a pivotal role in delivering high-quality products to meet diverse market needs. Embracing advancements in technology and automation will ensure that manufacturers remain competitive in an ever-changing environment, solidifying the significance of corrugated panel lines in modern manufacturing.