Ceiling Bar Roll Forming Machine Revolutionizing Ceiling Design

In the modern construction and interior design industry, innovation is key to achieving efficiency and quality. One such innovation that has made significant strides is the ceiling bar roll forming machine. This specialized equipment is designed to produce ceiling bars – the structural elements that support ceiling systems – with precision and speed. In this article, we will delve into the workings, benefits, and applications of ceiling bar roll forming machines.

Understanding Ceiling Bar Roll Forming Machines

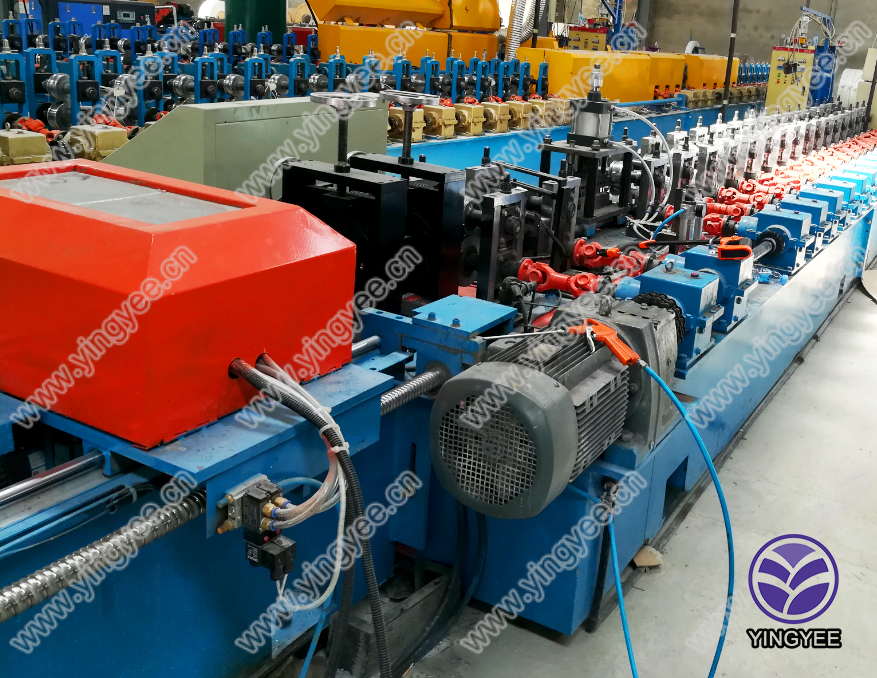

A ceiling bar roll forming machine is a type of industrial machinery used to convert flat metal sheets into various profiles needed for ceiling systems. The process involves feeding metal sheets into a series of rollers that gradually shape the metal into designated profiles. The output can range from simple flat bars to complex shaped components depending on the design requirements.

The machine operates by using a series of rollers, which are aligned in a specific sequence to gradually shape the metal sheet into the desired cross-section. As the metal passes through each roller, it is precisely formed into the intended profile. This method of production is not only efficient but also enhances the durability and consistency of the ceiling bars produced.

Advantages of Using a Ceiling Bar Roll Forming Machine

1. High Production Efficiency One of the primary benefits of using a ceiling bar roll forming machine is its ability to produce large quantities of ceiling bars quickly. This high-speed production capability is essential for large construction projects where time is a critical factor.

2. Cost-Effectiveness By automating the production process, manufacturers can significantly reduce labor costs and minimize waste. The precision of the roll forming process also ensures that metal is used efficiently, further lowering overall material costs.

3. Versatility Ceiling bar roll forming machines can be customized to produce a variety of shapes and sizes. This versatility allows manufacturers to cater to specific project requirements, whether they need standard profiles or unique designs.

4. Consistency and Quality The automated nature of roll forming ensures that each ceiling bar produced is consistent in size and quality. This uniformity is crucial in construction, where precision is vital for structural integrity and aesthetic appeal.

5. Reduced Labor Dependency With advanced technology, roll forming machines require fewer operators to manage the production line, reducing dependency on manual labor. This is especially beneficial in regions facing labor shortages.

Applications of Ceiling Bar Roll Forming Machines

Ceiling bar roll forming machines find a wide range of applications in various sectors. They are commonly used in

- Commercial Construction In office buildings, shopping malls, and industrial facilities, ceiling bars provide the essential framework for suspended ceilings and other design features.

- Residential Renovations Home improvement projects often require custom ceiling profiles to match existing decor, making roll forming machines an invaluable tool for contractors.

- Architectural Designs Unique, eye-catching ceiling designs are increasingly popular in modern architecture. Roll forming machines can create intricate patterns and shapes that elevate the aesthetic appeal of any interior space.

- Acoustic Ceilings The construction of acoustic ceilings, which are designed to reduce noise, often utilizes specialized ceiling bars. Roll forming machines can produce the specific profiles needed for these applications.

Conclusion

The ceiling bar roll forming machine represents a significant advancement in the production of ceiling support structures. Its efficiency, cost-effectiveness, and ability to produce high-quality, consistent products make it an essential tool in the construction and design industries. As architects and builders continue to push the boundaries of design, ceiling bar roll forming machines will play an integral role in bringing innovative concepts to life. Embracing this technology not only enhances the quality of construction projects but also streamlines processes, making it a worthwhile investment for manufacturers and contractors alike.