The Evolution of Wall Angle Making Machines in Gypsum Stud and Drywall Construction

In the ever-evolving world of construction technology, the demand for precision and efficiency has led to significant advancements in machinery. One of the standout innovations in this field is the wall angle making machine, particularly in the context of gypsum stud and drywall installation. This technology seeks to streamline the construction process while ensuring high-quality finishes, ultimately revolutionizing how walls are constructed.

Gypsum studs and drywall have become essential materials in modern construction due to their lightweight, fire-resistant, and soundproofing qualities. However, the installation of these materials requires a high level of accuracy and craftsmanship. Traditional methods often involved labor-intensive processes that could lead to inconsistencies and increased labor costs. This is where wall angle making machines come into play, offering a specialized solution designed to meet the unique demands of drywall installations.

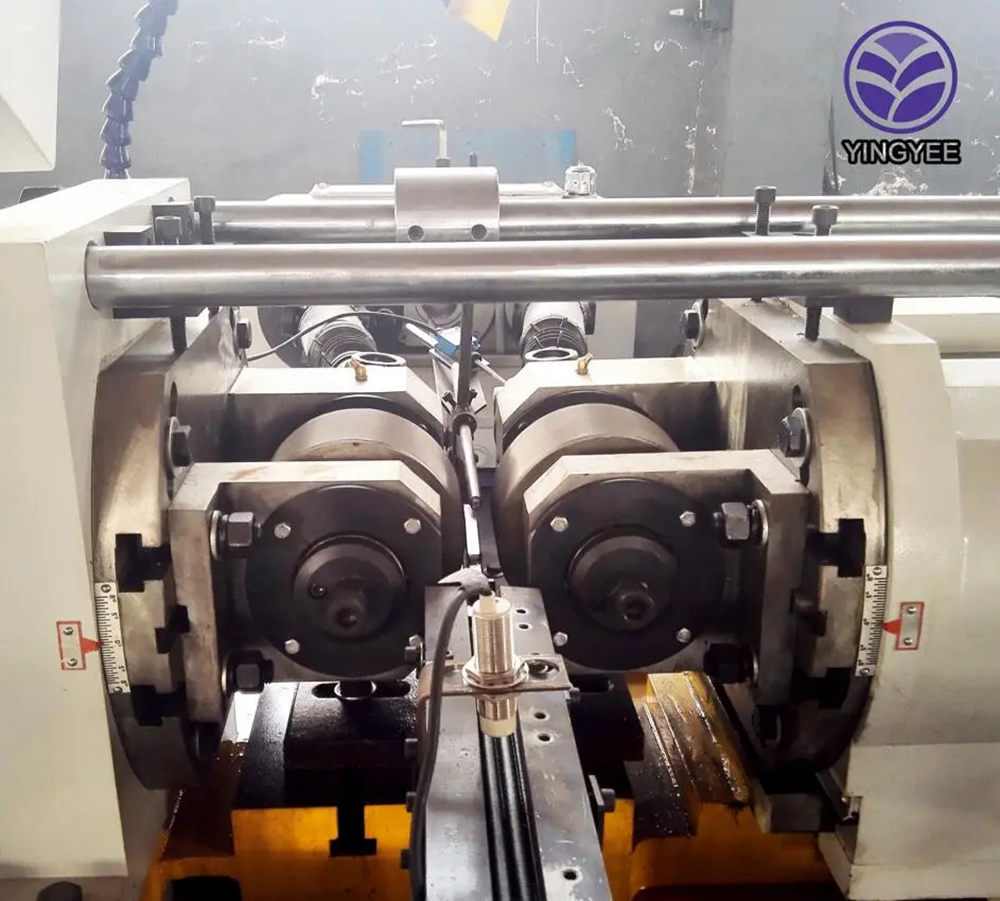

A wall angle making machine automates the production of corner angles used in drywall systems. These machines can create various angle types, ensuring that the drywall panels fit seamlessly at their joints. The precision offered by these machines allows for tighter seams and improved aesthetics, which are crucial in both residential and commercial settings. Furthermore, by utilizing advanced technology, such as computerized numerical control (CNC), these machines can produce components at a rapid pace, significantly reducing production time and labor costs.

In addition to efficiency, wall angle making machines contribute to sustainability in construction. By reducing waste during the manufacturing process and ensuring that materials are cut with pinpoint accuracy, these machines support more eco-friendly building practices. As the industry increasingly prioritizes sustainable methods, the adoption of such technology becomes not just advantageous but essential.

Moreover, wall angle making machines are designed to be user-friendly, with many models featuring intuitive interfaces that make it easier for operators to set up and adjust the machine for various production runs. This user-friendliness, combined with their versatility in producing different sizes and types of angles, allows construction companies to be agile and adapt quickly to project requirements.

As the construction landscape continues to change, the integration of wall angle making machines into the workflow of drywall installations is becoming more prevalent. This shift not only enhances the quality of construction but also improves overall productivity. The rise of automation in the industry, coupled with the increasing complexity of building designs, makes it crucial for construction professionals to embrace these technologies.

In conclusion, wall angle making machines are a testament to the advancements in the construction industry, particularly in the optimal use of gypsum studs and drywall. Their ability to enhance precision, efficiency, and sustainability makes them an invaluable asset in modern construction, paving the way for a new era of building practices that prioritize quality and speed. As the industry continues to evolve, these machines will undoubtedly play a pivotal role in shaping the future of wall construction.