The Evolution and Significance of Welding Rod Factories

Welding, an essential process in various industries, transforms metal components into durable structures and products. At the heart of this process lies the welding rod, a key element that ensures a strong and lasting bond between metals. Welding rod factories play a crucial role in manufacturing these vital tools, reflecting technological advancements and the growing demand for quality welding materials.

The Evolution and Significance of Welding Rod Factories

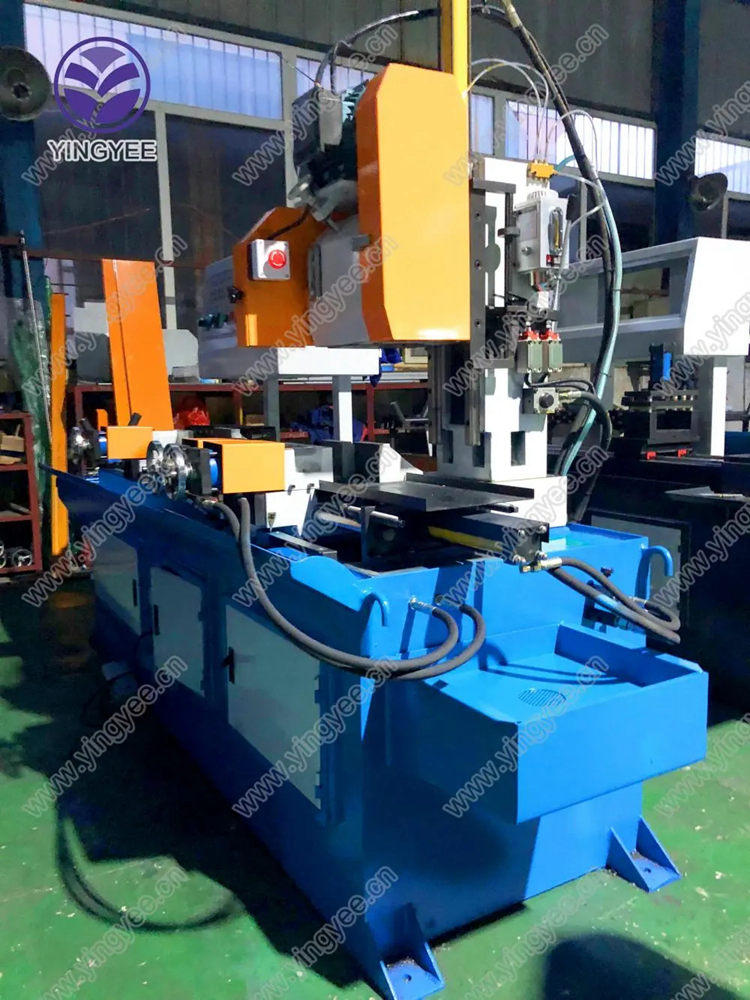

Welding rod factories can be traced to their rich technological lineage. Modern facilities utilize state-of-the-art machinery and automation systems, allowing for efficient production processes. From the raw materials stage to the final packaging of welding rods, each step is meticulously monitored to ensure quality control. This attention to detail is essential, as the properties of the welding rod influence the overall integrity of the weld and the performance of the end product.

One of the most significant advancements in welding rod production is the introduction of specialized rods tailored for specific applications. For instance, stainless steel rods are often used in food processing and chemical industries due to their resistance to corrosion. In contrast, high-strength low-alloy rods are favored in construction and heavy equipment manufacturing for their durability. These variations in welding rods underscore the importance of research and development within welding rod factories, as they strive to meet the diverse needs of their customers.

As global industrial markets continue to evolve, welding rod factories are adjusting their practices to embrace sustainability. With increasing environmental regulations and a shift toward greener technologies, many manufacturers have begun using recycled materials in their production processes. This not only reduces waste but also lowers the carbon footprint associated with the manufacturing of welding rods. By integrating eco-friendly practices, welding rod factories contribute to a more sustainable future while maintaining their commitment to quality.

Furthermore, training and workforce development are critical components of modern welding rod factories. Skilled workers are vital to maintaining high standards of production. Factories invest in regular training programs to ensure that employees are well-versed in the latest technologies and best practices. This commitment to workforce education not only enhances productivity but also fosters innovation and creativity within the production process.

In conclusion, welding rod factories represent a critical intersection of technology, craftsmanship, and sustainability within the manufacturing landscape. As industries worldwide continue to rely on welding for construction, repair, and fabrication, the role of these factories becomes increasingly vital. By embracing innovation, quality control, and sustainable practices, welding rod factories are well-positioned to meet the challenges of the future, ensuring that they continue to provide the essential tools that make modern construction and manufacturing possible.