Exploring the Rolling Door Machine Factory Innovations in Manufacturing

In the realm of modern manufacturing, the rolling door machine factory stands out as a vital contributor to the production of high-quality rolling doors. These doors, renowned for their durability, security, and space efficiency, have become essential in various sectors including industrial, commercial, and residential markets. Within the factory setting, advanced machinery and innovative technology converge to create these versatile products, paving the way for enhanced operational efficiency and customer satisfaction.

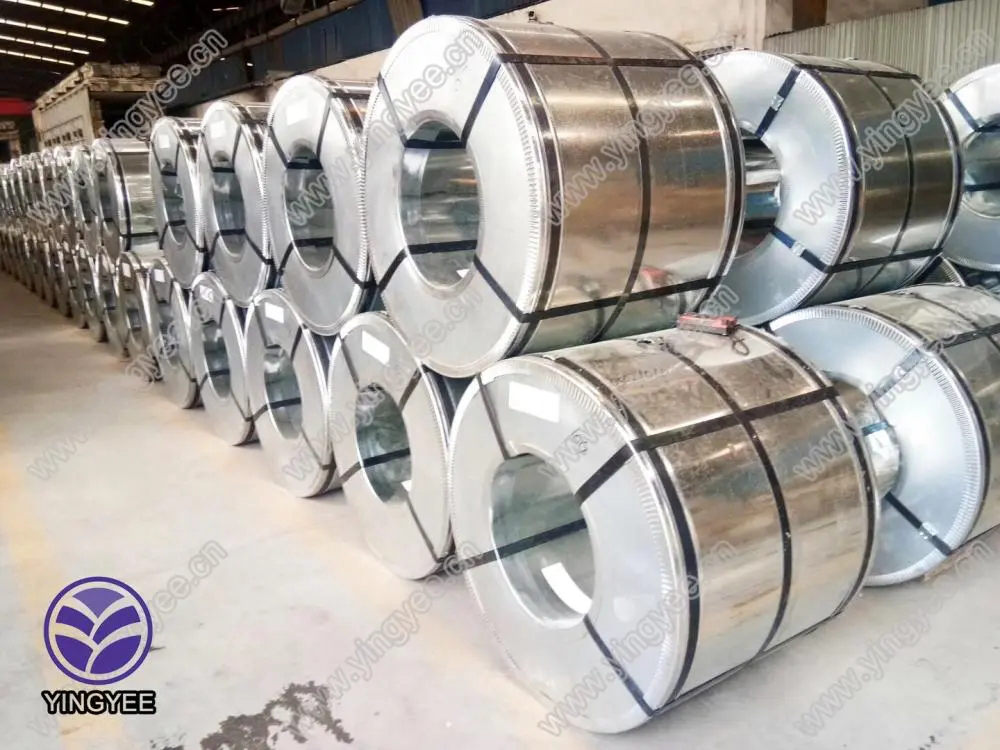

At the heart of a rolling door machine factory lies the machinery designed specifically for the manufacturing process. These machines are engineered to cut, shape, and assemble the components of rolling doors with remarkable precision. High-speed laser cutting machines, for instance, ensure that metal sheets are processed swiftly and accurately, laying the groundwork for sturdy door panels. Next in the line is the forming machine, which bends and shapes the cut sheets into the desired rolling door profiles. This seamless integration of technology not only boosts productivity but also significantly reduces material wastage, promoting a more sustainable manufacturing approach.

Quality control is a paramount concern in the rolling door machine factory. Each step of the production process is meticulously monitored to uphold the highest standards. Automated inspection systems, equipped with advanced imaging technology, scan finished products for any defects before they leave the factory floor. This commitment to quality assurance instills confidence in customers and reinforces the factory's reputation for delivering reliable and robust rolling doors.

Another crucial aspect of a rolling door machine factory is the workforce. Skilled technicians and engineers play a vital role in overseeing the operation of complex machinery and ensuring that production runs smoothly. Continuous training and development programs are essential to keep staff abreast of the latest technological advancements. By investing in human capital, the factory not only enhances its operational efficiency but also fosters a culture of innovation where employees are encouraged to contribute ideas and improvements.

In addition to manufacturing rolling doors, these factories often engage in research and development to explore new materials and designs. The evolution of rolling doors has led to the introduction of features such as enhanced insulation, greater security options, and aesthetic customization. Sustainability has also emerged as a key focus, with manufacturers exploring eco-friendly materials and energy-efficient production processes.

Partnerships with suppliers further enhance the capabilities of rolling door machine factories. By collaborating with material suppliers, manufacturers can gain access to cutting-edge resources that improve product quality and manufacturing efficiency. This symbiotic relationship fosters innovation and drives industry advancements.

In conclusion, the rolling door machine factory is a cornerstone of the modern manufacturing landscape. Through advanced machinery, a dedicated workforce, and a commitment to quality and innovation, these facilities produce rolling doors that meet the diverse needs of today’s consumers. As technology continues to evolve and sustainability becomes increasingly vital, rolling door machine factories are poised to redefine their role in the industry, ensuring that they remain at the forefront of manufacturing excellence. With ongoing innovation and a focus on quality, the future of rolling door production looks bright, catering to an ever-evolving marketplace.